MAINTENANCE PROCEDURES

TB24 Plus&26J Plus Maintenance Manual 5-25 © Jun 2022

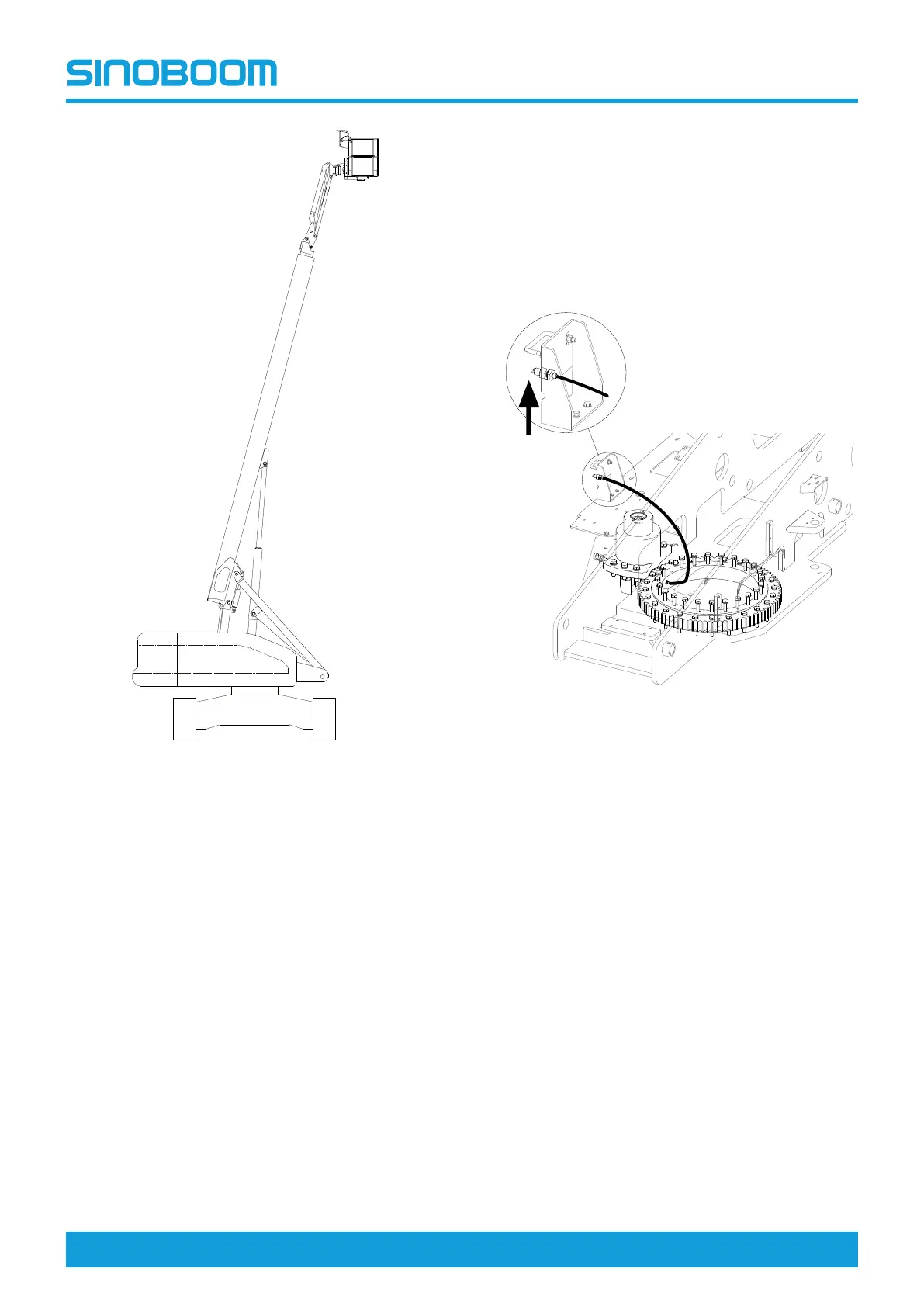

Figure 5-33

1. Fully retract the boom and raise to full height.

2. Locate the connecting bolts between turntable and

slewing bearing.

3. As indicated by the arrow Fig 5-30 , page 5-24,

insert 0.04mm feeler gauge in between the bolt and

washer.

4. Ensure the feeler gauge won’t go through the

outside of bolt head to the bolt shank.

5. Lower the main boom to horizontal position, and

fully extend the main boom.

6. As indicated by the arrow Fig 5-30 , page 5-24,

insert 0.04mm feeler gauge in between the bolt and

washer.

7. Ensure the feeler gauge won’t go through the

outside of bolt head to the bolt shank.

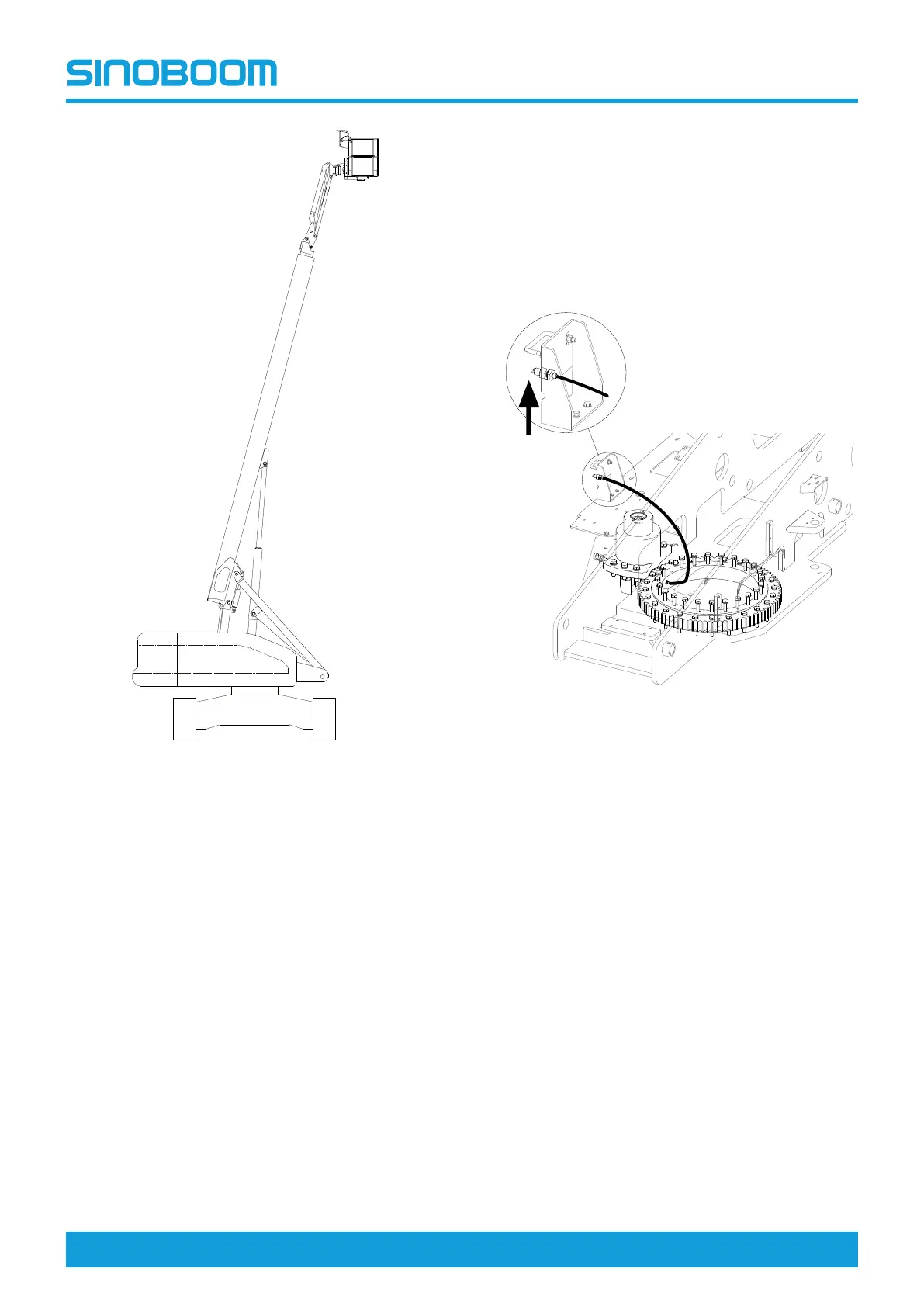

B-14 Lubricate Slewing Bearing

Regulary lubricating the slewing bearing from a long

distance is vital to proper machine operation. The

Lubricating frequency and the amount of lubricant used

should be increased if the machine is operated on

successive work shifts or in hostile environment.

• Lube point:1 grease nipple (see the following

figure)

Figure 5-34

• Amount:as needed

• Lubricant:ZL-3 lithium based grease

B-15 Inspect Platform Rotate Cylinder

Fasteners

Regularly inspecting the platform rotate cylinder

fasteners is vital to proper and safe machine operation.

Loading...

Loading...