MAINTENANCE PROCEDURES

TB24 Plus&26J Plus Maintenance Manual 5-23 © Jun 2022

7. TB26J Plus:when the boom extends to the

farthest(the ground display reads 17.91m of boom

length), the buzzers at the ground and platform

controls should be sounding, boom further

extending and boom up/down should be restricted,

but boom retracting and turntable rotating should be

allowed.

8. Using the main boom telescope switch, retract the

boom.

9. The boom can be fully retracted.

Inspecting angle sensor

1. Turn the Ground/Platform select switch at ground

controls to the Ground.

2. Pull out the emergency stop button at the ground

controls to ON position.

3. Turn the key switch at ground controls to ON

position.

4. Using the main boom lift and jib up/down function(if

equipped), adjust the main boom and jib boom(if

equipped) to horizontal.

5. Using the main boom telescope function, extend

the main boom.

6. When the main boom is raised to the upper limit of

lift angle(ground display reads 70°[±1°]), the boom

should be prevented from further raising.

7. When the main boom is lowered to the lower limit of

lift angle(ground display reads -12°[±1°]), the boom

should be prevented from further lowering.

8. Using the boom telescope and up/down function,

retract and lower the boom.

9. The boom can be fully retracted.

Note:The allowable tolerance of angle sensor do not

exceed 0.5° through the full metering range.

B-10 Inspect Engine Exhaust System

Inspecting engine exhaust system is vital to proper

engine operation and extending service life.

NOTICE

Shut off the engine before inspection.

1. Inspect whether the engine exhaust pipe is

damaged or crushed flat.

2. Inspect whether the exhaust pipe is tightly

connected.

3. Inpsect whether the muffler shows signs of heating

fatigue or possiblity of interal malfunction.

4. Inspect the catalytic converter for blockage.

5. Tighten or replace parts, if needed, to ensure the

exhaust system is free of leakage.

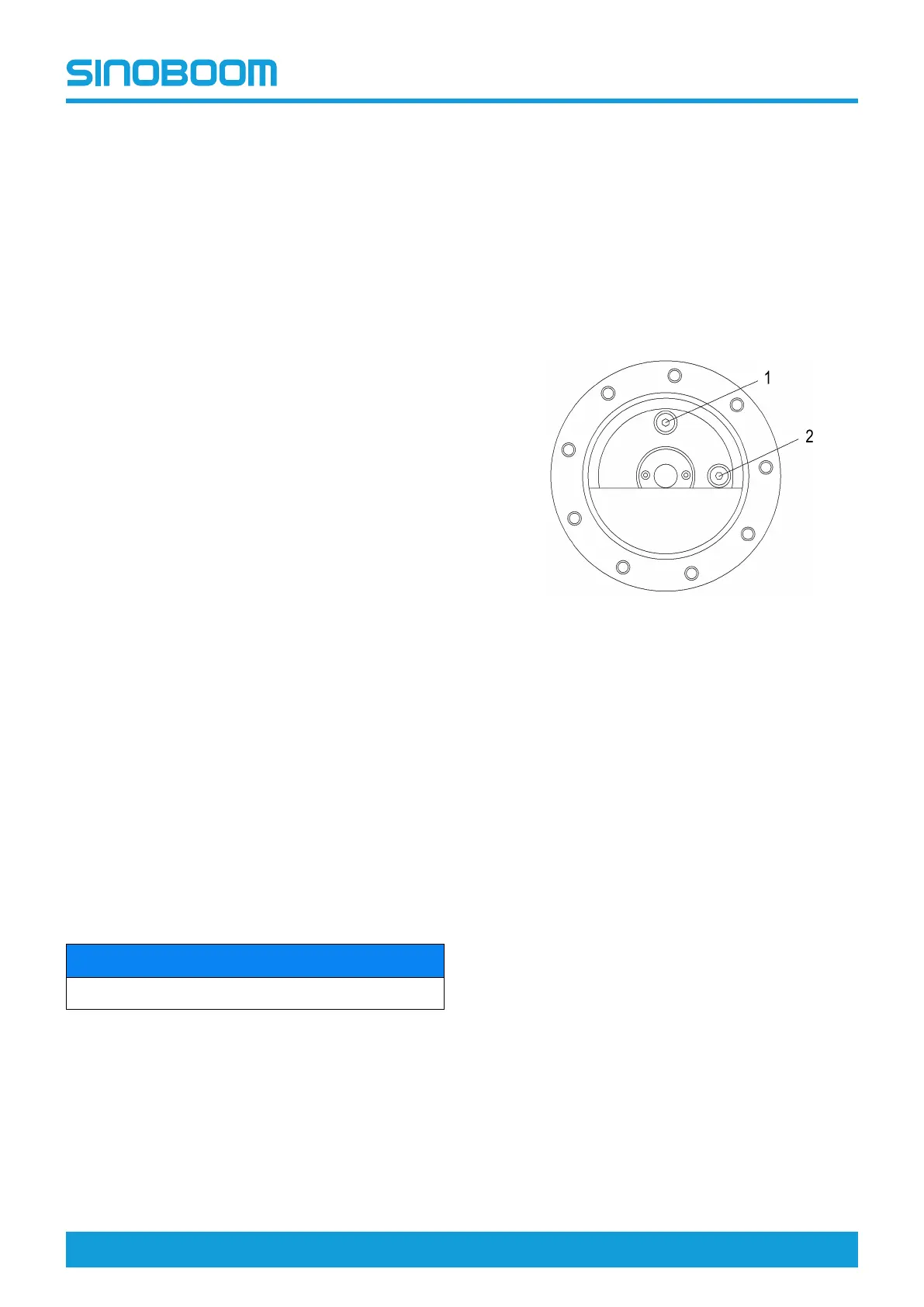

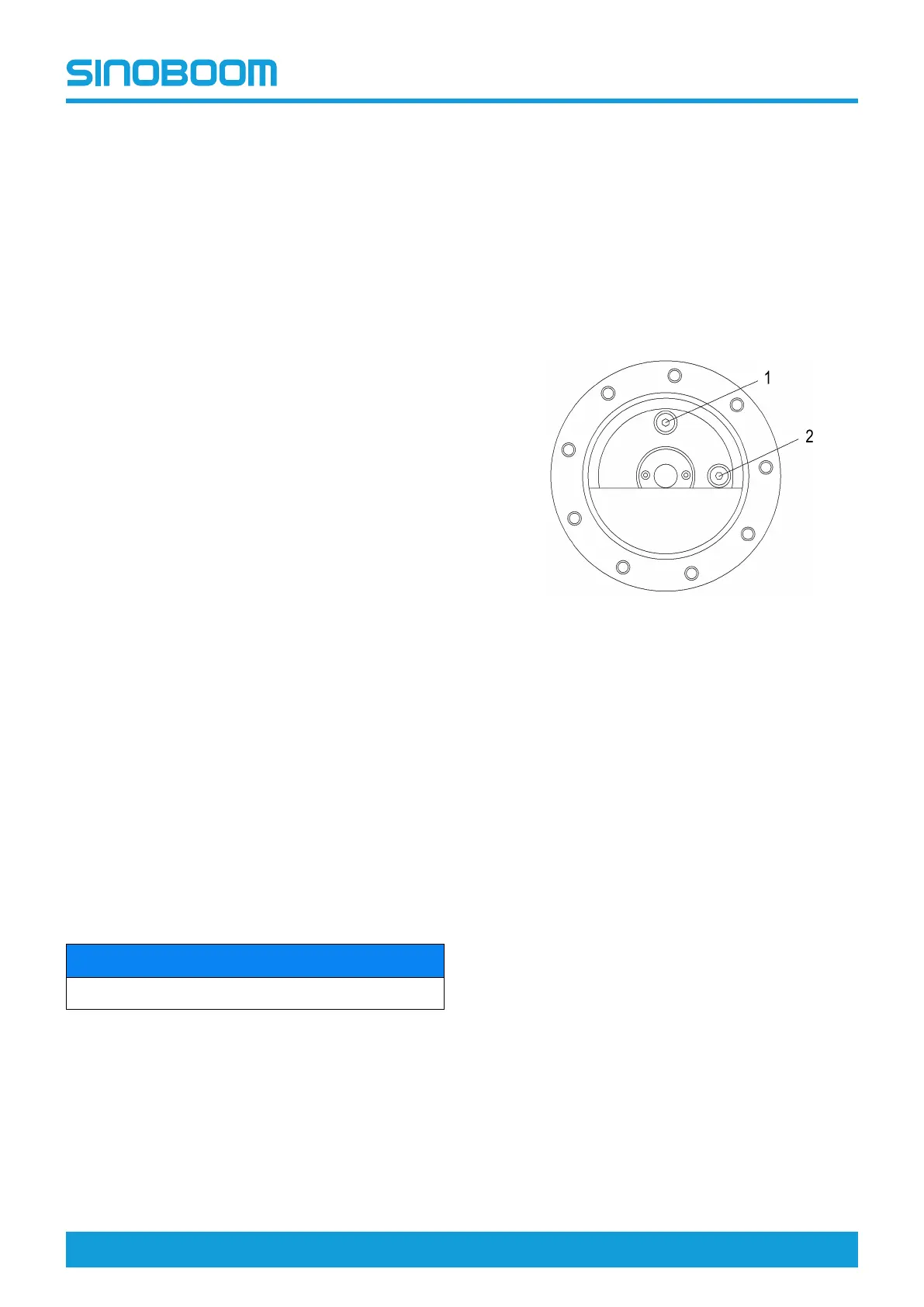

B-11 Inspect Drive Reducer Oil Level

Inappropriate gear oil level of drive reducers will reduce

the machine performance, and continued use could

result in component damage.

1. Drive the machine to rotate the reducer until one

bolt at top and the other one at 90 degrees, as

shown in the figure below.

Figure 5-29

2. Remove the bolt #2, and check the oil level.

3. The oil level should be even with the bolt hole.

4. If necessary, add oil to the bolt hole.

5. Remove the bolt #1, add gear oil to the bolt hole #1

until the oil level is even with that of the bolt hole #2.

6. Install the bolts back.

7. Clean up the gear oil spills during the inpection.

8. Perform this inspection procedure to all drive

reducers of the machine.

B-12 Inspect Slewing Reducer Oil

Level

Inappropriate gear oil level of slewing reducers will

reduce the machine performance, and continued use

could result in component damage.

Loading...

Loading...