REPAIR PROCEDURES

TB24 Plus&26J Plus Maintenance Manual 6-3 © Jun 2022

Jib Boom Assembly (TB26J Plus only)

MOVING OBJECT HAZARD

Wear eye protection when tapping

the brass drift with a wooden

hammer.

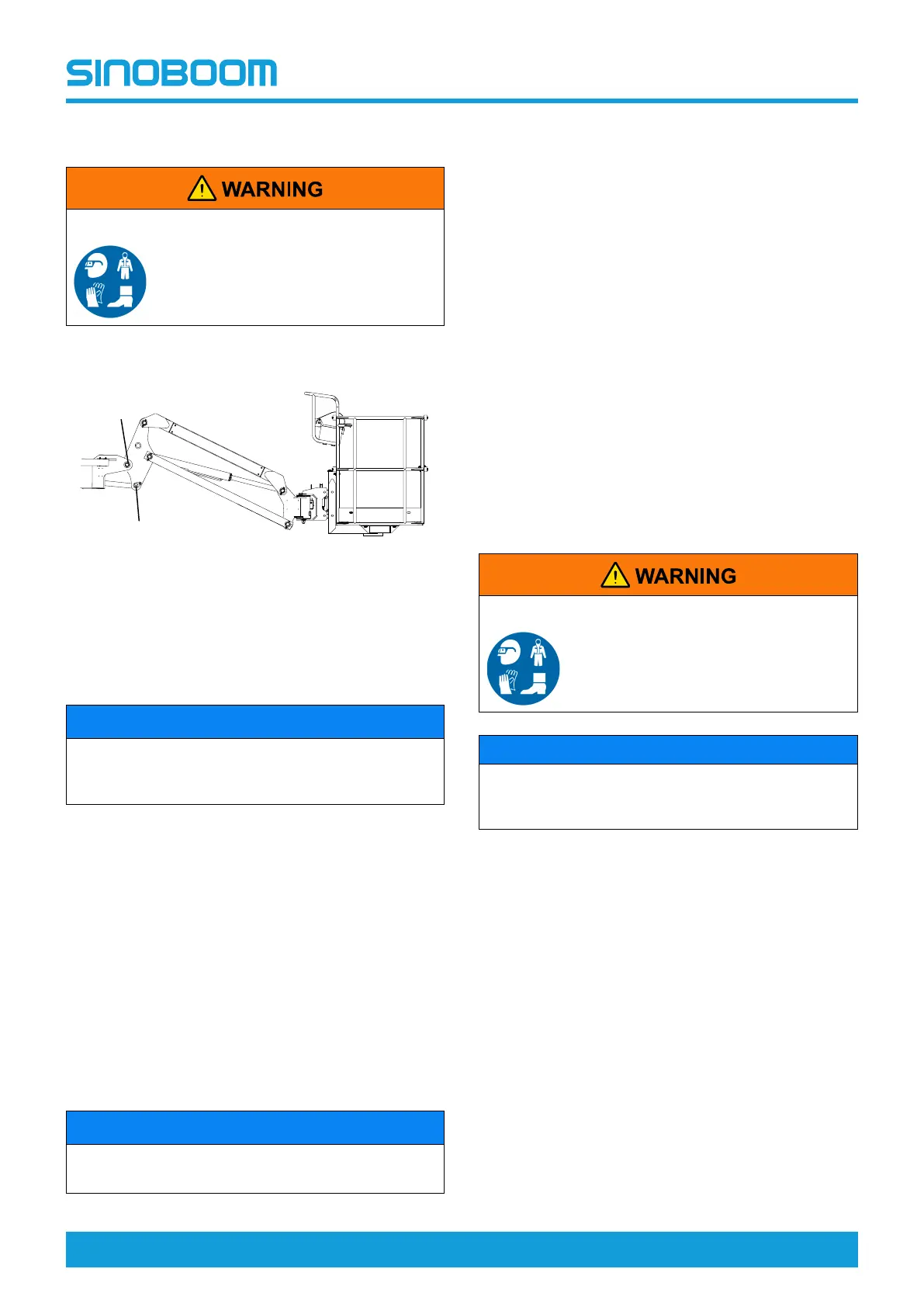

Figure 6-3

Removing the jib boom assembly

NOTICE

When removing the hose and fitting, the O-ring on

the fitting and hose end must also be removed,

replaced and tagged.

1. Position the main boom horizontal, and attach the

jib boom assembly to a suitable crane.

2. Use a suitable device to support the upper level

cylinder.

3. Remove the fasteners at the pivot pin 1# of upper

level cylinder, and drive the pivot pin 1# out using a

brass drift and wooden hammer.

4. Remove the fasteners at the pivot pin 2#, and drive

the pivot pin 2# out using the brass drift and

wooden hammer.

5. Using the crane, slowly lift the jib boom assembly

off the main boom.

Inspecting the jib boom assembly

NOTICE

When inspecting the pins and bearings, please see

Pins and composite bearing, page 4-5.

• Check the pivot pins for wear, scratch, deformation

or other damages, and replace if needed.

• Check the inside of bearings for wear, scratch,

deformation or other damages, and replace if

needed.

• Check the jib lift cylinder connecting pins for wear,

scratch, deformation or other damages. Before

installation, ensure the pin surface is subject to

protective treatment. Replace if needed.

• Check the inside of the bearings connecting the

platform rotate motor for wear, scratch, deformation

or other damages, and replace if needed.

• Check all threaded parts for elongation, thread

deformation, torsion or other damages, and replace

if needed.

• Check all structures of jib boom assembly for

deformation, cracks, weld detachment or other

damages, and replace the jib boom if needed.

Platform Level Cylinder

MOVING OBJECT HAZARD

Wear eye protection when tapping

the brass drift with wooden hammer.

NOTICE

When removing the cylinder, special care should be

taken to avoid the fall of the cylinder and component

damage.

The machine is configured with 2 platform level

cylinders located at the boom upper end and lower end.

The platform level cylinder is used for maintaining the

platform level (in relation to the turntable) through the

entire range of motion.

1. Extend the boom until the platform level cylinder

rod-end pivot pin is accessible.

2. Slightly raise the boom and place a support under

the platform.

3. Lower the boom until the platform sits on the

support. Take special care not to press the total

weight of boom over the support.

4. Disconnect and plug the hydraulic lines to the

platform level cylinder.

5. Remove the retaining screw from the rod-end pivot

pin #1 of the platform level cylinder. And do not

move the pivot pin.

Loading...

Loading...