MAINTENANCE PROCEDURES

TB24 Plus&26J Plus Maintenance Manual 5-35 © Jun 2022

2. Place a suitable vessel under the bolt as indicated

by the arrow in the figure.

3. Remove the bolt as indicated.

4. Fully drain the drive reducer gear oil to the vessel.

5. Mount back the loosened bolt.

6. Drive the machine to rotate the reducer until one

bolt is at top and the other is at 90 degrees.

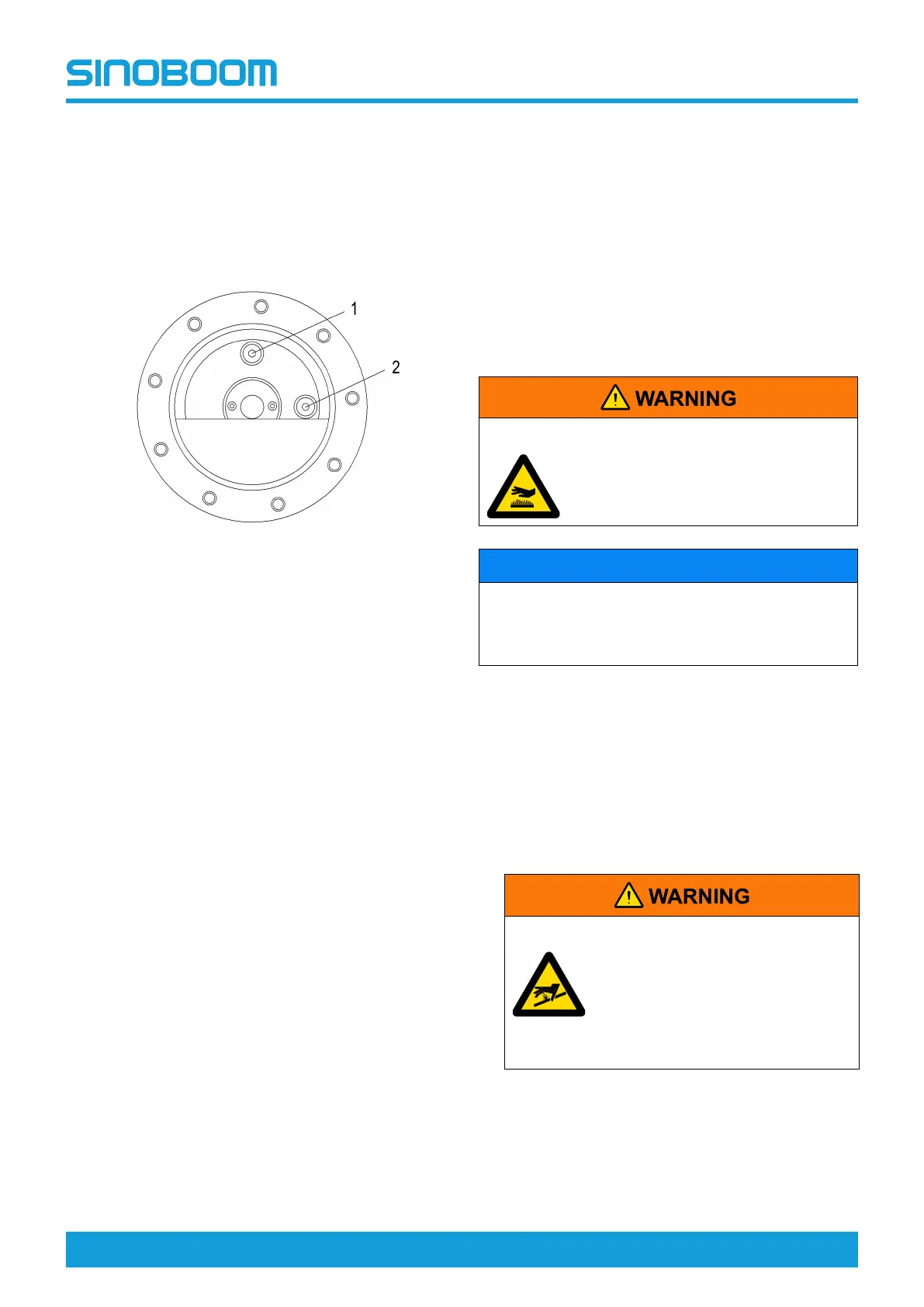

Figure 5-52

7. Remove the #1 and #2 bolts as indicated.

8. Add new gear oil to the port #1 until the oil level is

even with that of the port #2.

9. Mount back the bolts.

10. Clean up the oil spills in performing the inspection

procedure.

11. Perform the same procedure on all drive reducers

of the machine.

D-2 Replace Slewing Reducer Gear Oil

Regularly replacing slewing reducer gear oil is vital to

good machine performance and extending reducer

service life.

1. Open the left side cover of turntable, and locate the

slewing reducer.

2. Place a suitable vessel under the drain plug of the

slewing reducer.

3. Remove the drain plug.

4. Fully drain the slewing reducer gear oil to the

vessel.

5. Mount back the drain plug.

6. Remove the fill plug (for the location, reference B-

12 Inspect Slewing Reducer Oil Level, page 5-

23), add new gear oil to the fill port until the oil level

is even with the bottom of the fill plug.

7. Mount back the fill plug.

8. Clean up the gear oil spills in performing the

inspection procedure.

D-3 Replace Hydraulic Oil

Regularly replacing hydraulic oil is vital to good

machine performance and extending service life.

Unqualified cleanliness of oil may cause the machine to

perform poorly and continued use may result in

hydraulic component damage. Particularly harsh

working condition requires the oil changes to be

performed more frequently.

BURN HAZARD

Before servicing the hydraulic

system, allow the hydraulic oil to

cool down to room temperature.

NOTICE

The inspection must be performed with the engine in

off position.

When removing the hose and fittings, the O-rings on

the hose and fittings must be replaced.

1. Open the left side cover of turntable, and locate the

hydraulic tank.

2. Close the hydraulic shutoff valve located on the

side of hydraulic tank.

3. Remove the drain plug at the bottom of the tank,

and completely drain the oil into a suitable vessel.

For the capacity of hydraulic tank, please reference

Machine Specifications, page 2-1.After the oil is

completely drained, re-install the drain plug.

HIGH PRESSURE HAZARD

Slowly remove the hydraulic

elements to reduce the oil

pressure. High oil pressure may

penetrate the skin. Should any

injury occur, go to a doctor at

once.

4. Disconnect and plug the suction hoses.

5. Disconnect and plug the return hoses.

6. Remove the retaining bolts from the hydraulic tank

cover, and remove the hydraulic tank cover.

Loading...

Loading...