© Jun 2022 5-34 TB24 Plus&26J Plus Maintenance Manual

MAINTENANCE PROCEDURES

C-5 Replace Air filter of Hydraulic Tank

Keeping the breather cap of hydraulic tank in well-

ventilated condition is vital to normal operation of

hydraulic pump and extending service life. Dirty or

blocked air filter of hydraulic tank may cause the

hydraulic pump to suction improperly, and continued

operation may result in component damage. The air

filter of hydraulic tank should be inspected more often

in hostile operating environment.

1. Using a wrench, remove the air filter of hydraulic

tank(located as shown inFig 5-21 , page 5-20).

2. Install and tighten the new filter.

C-6 Inspect Weighing System

Before the test, move the boom fully up and down and

telescope in and out for at least twice to ensure the

pulley and track are adequately lubricated.

Table 5-14

MODELS TEST RESULTS

TB24 Plus&26J

Plus (KG mode)

Under restricted configuration:

When the load does not exceed 454kg (1000 lb) , ensure that the platform is able to lift to the

highest position.

when the load exceeds 454kg (1000 lb) , the buzzer will sound continuously, the overload

indicator light will flash, the display screen will indicate platform overload, all motion functions

are restricted and will not resume until the excessive load is removed.

Under unrestricted configuration:

the load does not exceed 300kg (661 lb) , ensure that the platform is able to lift to the highest

position.

when the load exceeds 300kg (661 lb) , the buzzer will sound continuously, the overload

indicator light will flash, the display screen will indicate platform overload, all motion functions

are restricted and will not resume until the excessive load is removed.

TB24 Plus&26J

Plus (non-KG

mode)

Under restricted configuration:

When the load does not exceed 454kg (1000 lb) , ensure that the platform is able to lift to the

highest position.

When the load exceeds 454kg (1000 lb) , the buzzer will sound continuously, the overload

indicator light will flash, the display screen will indicate platform overload, some motion

functions will be restricted, but boom retracting, turntable rotating and boom lowering after fully

retracted is allowed. All motion functions will not resume until the excessive load is removed.

Under unrestricted configuration:

When the load does not exceed 300kg (661 lb) , ensure that the platform is able to lift to the

highest position.

When the load exceeds 300kg (661 lb) , the buzzer will sound continuously, the overload

indicator light will flash, the display screen will indicate platform overload, some motion

functions will be restricted, but boom retracting, turntable rotating and boom lowering after fully

retracted is allowed. All motion functions will not resume until the excessive load is removed.

CHECKLIST D

PROCEDURES

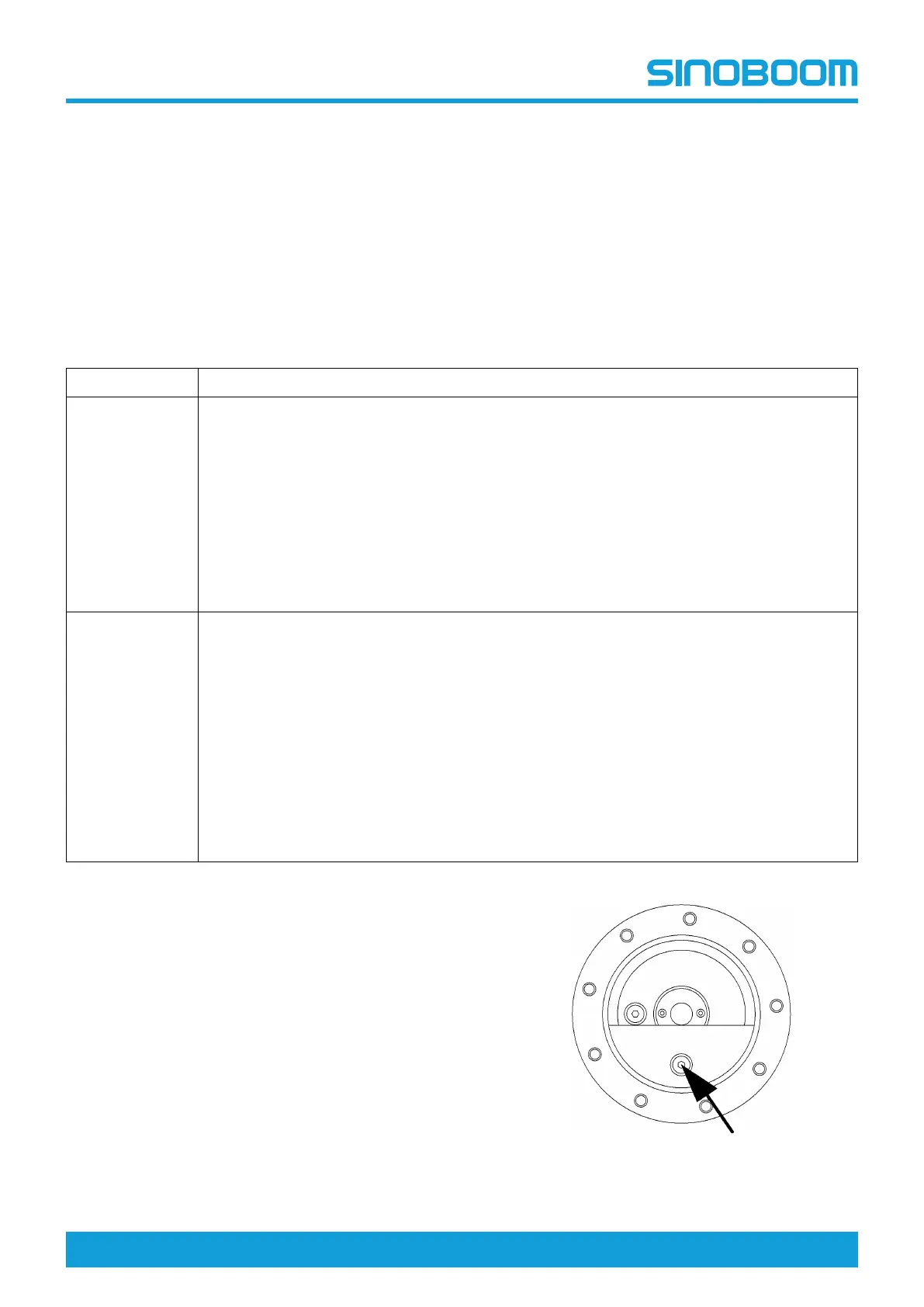

D-1 Replace Drive Reducer Gear Oil

Regularly replacing drive reducer gear oil is vital to

good machine performance and extending service life

of the reducer.

1. Drive the machine to rotate the reducer to the

position with one bolt at the bottom, as shown in the

figure below.

Figure 5-51

Loading...

Loading...