REPAIR PROCEDURES

TB24 Plus&26J Plus Maintenance Manual 6-7 © Jun 2022

Installing tires and rims

It is extremely important to apply and maintain proper

wheel mounting torque.

UNSAFE OPERATION HAZARD

• Use the wheel nuts that suit the

rim bolts. The wheel nuts must be

installed and maintained at the

proper torque to prevent loose

wheels, broken studsand possible

dangerous separation of wheels

from the axle, Be sure to only use

the nuts matched to the cone

angle of the wheel.

• Tighten the lug nuts to the proper

torque to prevent wheels from

coming loose, Use a torque

wrench to tighten the fasteners. If

you do not have a torque wrench,

tighten the fasteners with a socket

wrench, then immediately have a

service garage or dealer tighten

the lug muts to the proper torque.

Over-tightening will result in

breaking the studs or

permanently deforming the

mounting stud holes in the

wheels.

The proper procedure for attaching wheels is as

follows:

1. First apply the threadlocker Loctite 272 to the nuts,

then hand tighten all nuts to prevent the bolts and

nuts becoming loose. Do not use a lubricant on

threads or nuts.

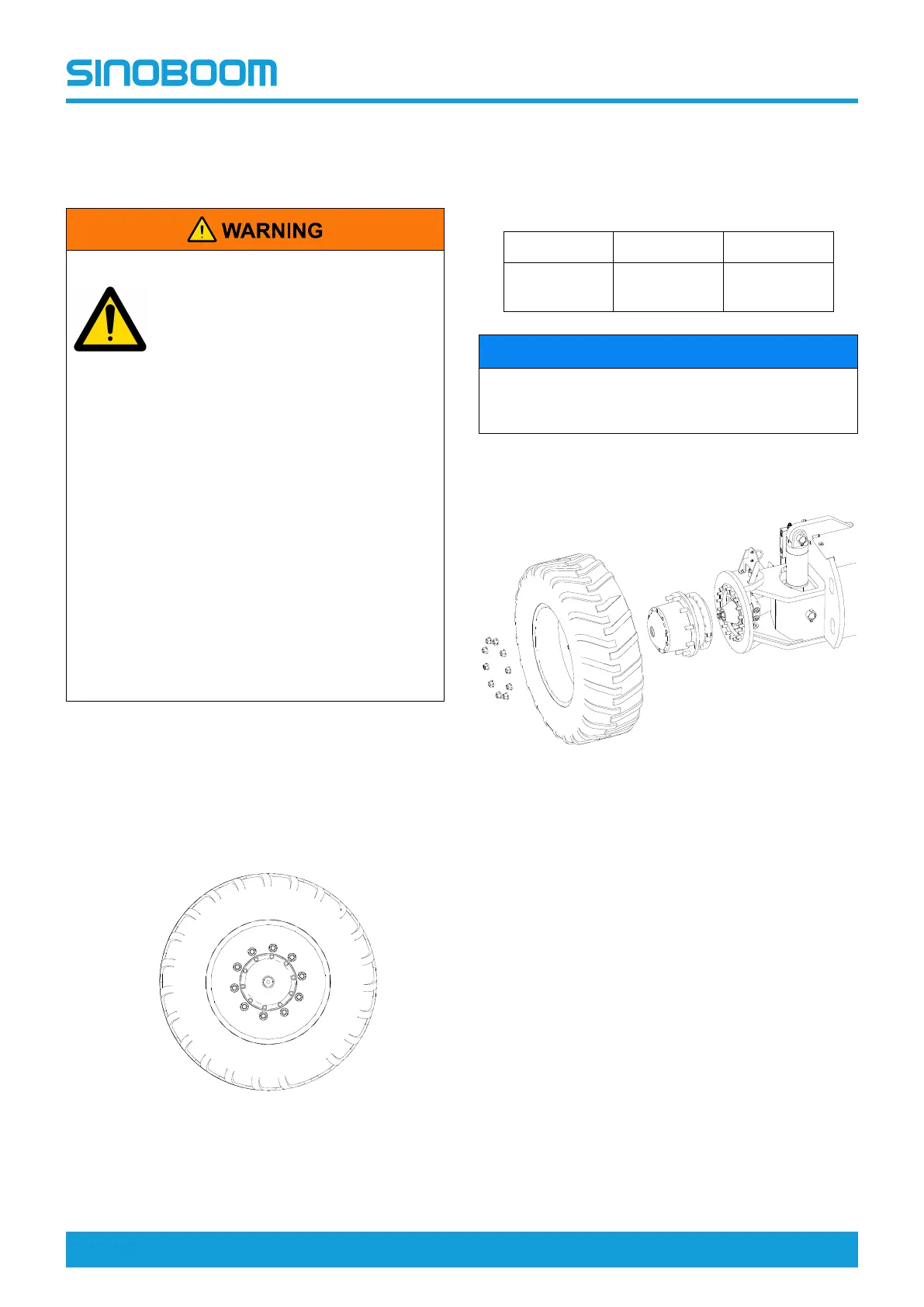

2. Tighten the nuts in the sequence as shown below.

Figure 6-13

3. The tightening of the nuts should be done in stages.

Following the recommended sequence, tighten nuts

per wheel torque as listed in the table below.

Table 6-1

1st Stage 2nd Stage 3rd Stage

250Nm

(185ft-lb)

550Nm

(406ft-lb)

700Nm

(517ft-lb)

NOTICE

Wheel nuts should be torqued prior to first use of

machine and after each wheel removal. Check

torque every 3 months or 150 hours of operation.

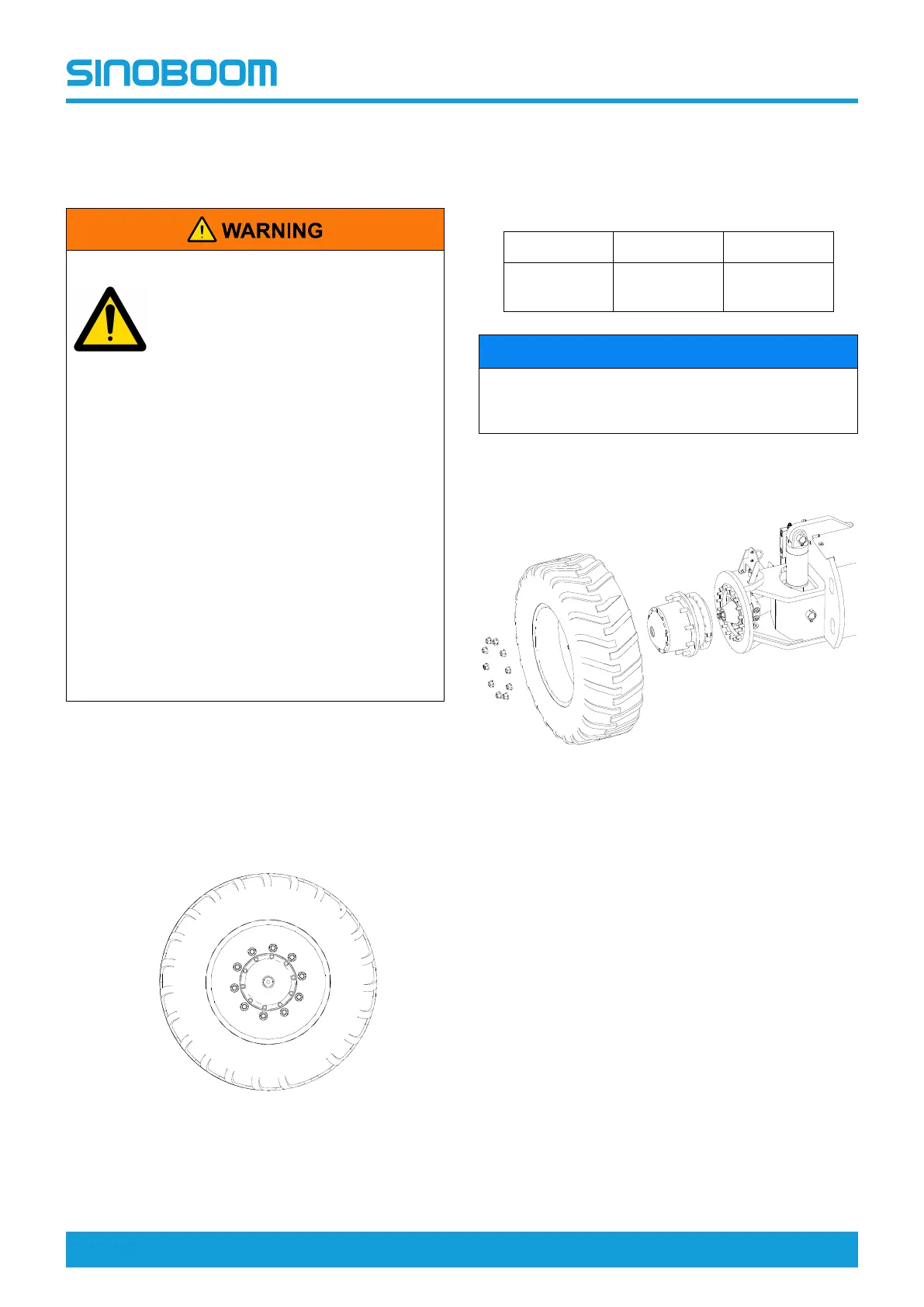

Reducer and Drive Motor

Figure 6-14

Loading...

Loading...