© Jun 2022 5-26 TB24 Plus&26J Plus Maintenance Manual

MAINTENANCE PROCEDURES

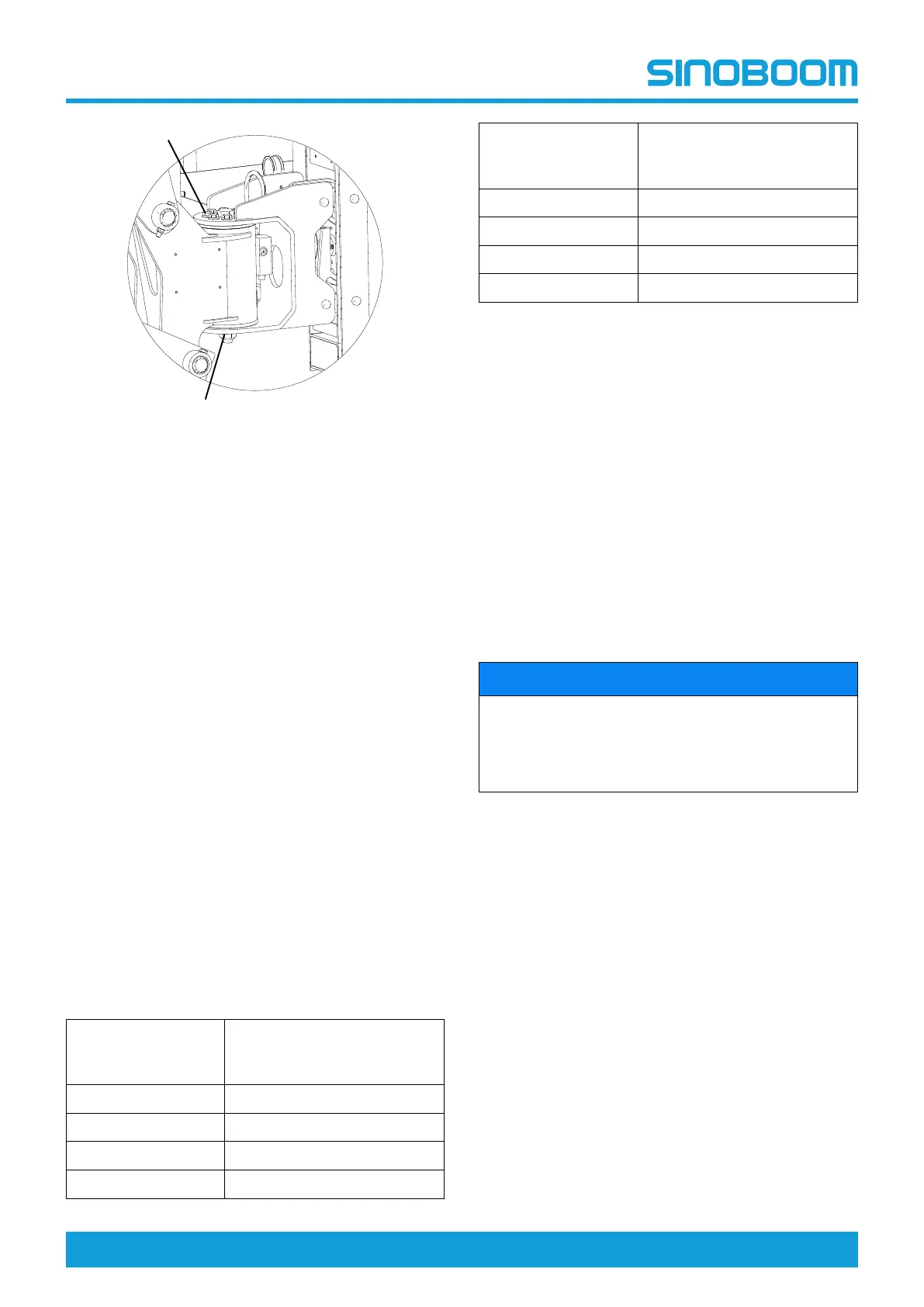

Figure 5-35

1. Place the machine in stowed position.

2. Locate the platform rotate motor.

3. Inspect whether the bolt #1 as indicated in the

above figure is properly torqued to specification

(125Nm[92ft-lb]).

4. If necessary, replace the bolt, torque to specified

value, and apply threadlocker Loctite 272.

5. Inspect whether the nut #2 as indicated in the

above figure is properly torqued to specification

(630Nm[465ft-lb]).

6. If the bolt needs to be replaced, be sure to toruqe to

specification.

B-16 Test Cylinder Drift

Platform drift

Measuring the drift from platform to ground: with rated

load on platform and power off, fully extend the main

boom. The maximum allowable drift in 10 minutes is

50mm (1.97 in). If the test result exceeds this value,

please proceed as below.

Cylinder drift

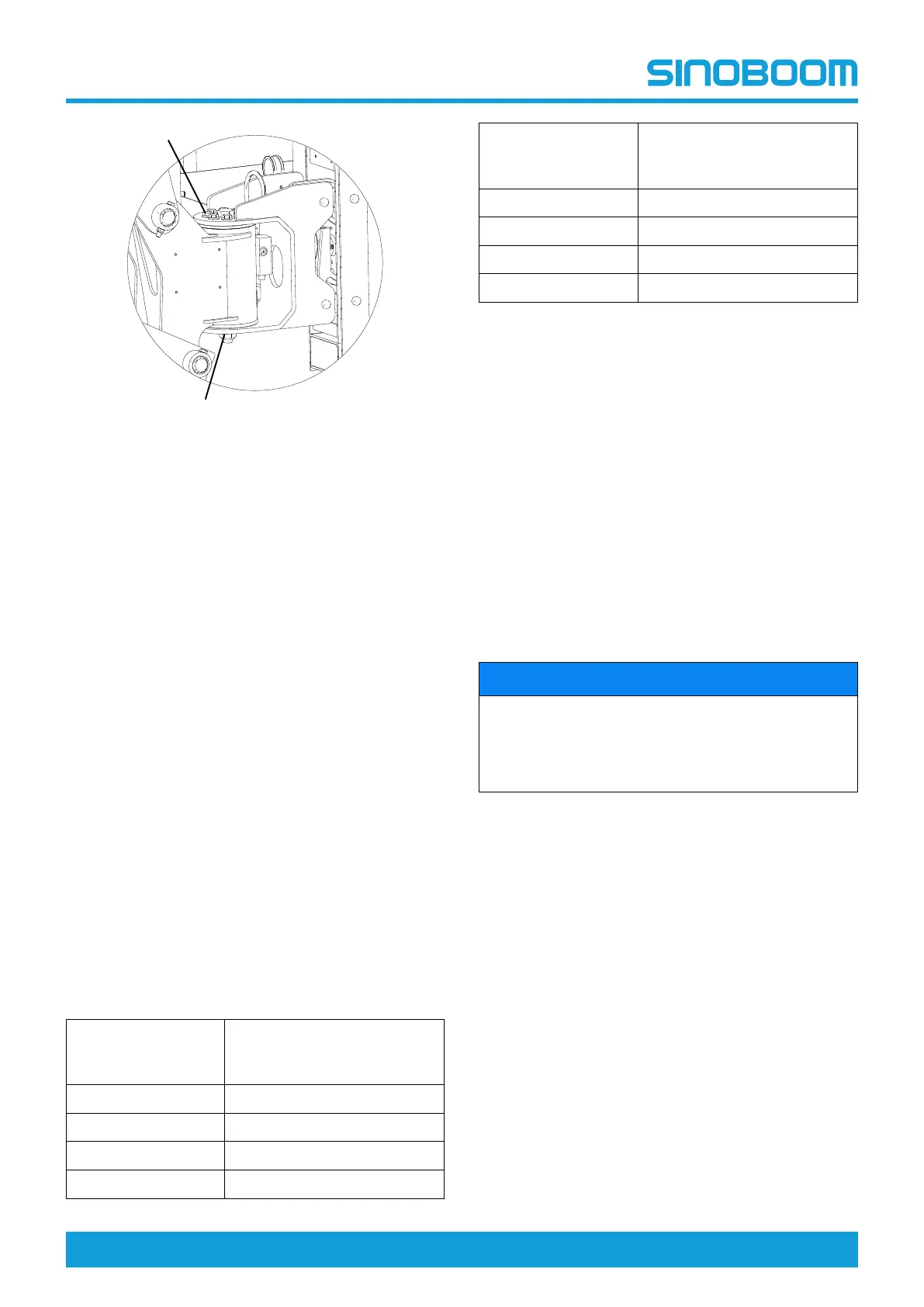

Table 5-12

Cylinder Bore

Diameter

(mm/in)

Maximum Allowable Drift in

10 Minutes

(mm/in)

63/2.48 0.96/0.037

80/3.15 0.63/0.025

100/3.94 0.39/0.015

125/4.92 0.23/0.009

Cylinder Bore

Diameter

(mm/in)

Maximum Allowable Drift in

10 Minutes

(mm/in)

160/6.30 0.14/0.006

180/7.09 0.13/0.005

200/7.87 0.10/0.0038

220/8.66 0.08/0.0030

• Measure drift at cylinder rod with a calibrated dial

indicator.

• The oil in cylinder must be at ambient temperature

and consistent.

• The cylinder must be applied with normal load from

the platform.

• The cylinder is acceptable if it passes this test.

NOTE: This information is based on 6 drops per minute

cylinder leakage. Since the hydraulic oil expands or

contracts due to thermal effect, thus the test value of

cylinder drift may have a tolerance of 7/10000 for each

temperature change of 1℃.

B-17 Test Counterbalance Valve

Locking

NOTICE

After exhausting the oscillate cylinders, test the

counterbalance valve locking, thereafter test the

oscillate system quarterly, or after replacing any

system component, or when any system malfuction

is discovered.

1. Place a 120mm (4.7 in)wooden block with bevel

side in front of the front left wheel of the machine.

2. Extend the boom by at least 1.2m to place the

machine in operating position.

3. Drive the machine to rest the front left wheel on the

wooden block.

4. Slowly rotate the turntble to the right by 90 degrees.

5. The rear detection indicator light will illuminates,

move the function switches to keep the boom

horizontal and fully extended.

6. Inspect the oscillate cylinder, ensure the oscillate

cylinder on the side with load applied is without any

evidence of retracting, and then retract the boom.

7. Move the reverse drive switch to drive the machine

off the wooden block.

8. The assistant on the ground should inspect whether

the wheel on the front left or rear right still remains

off the ground, and keept it elevated.

Loading...

Loading...