© Jun 2022 5-36 TB24 Plus&26J Plus Maintenance Manual

MAINTENANCE PROCEDURES

7. Rinse out the inside of the tank using a mild solvent,

and open the drain plug to empty the solvent.

8. After the hydraulic tank becomes dry, re-install the

hydraulic tank cover and attach the suction hose

and return hose to the hydraulic tank.

9. Add new hydraulic oil as needed.

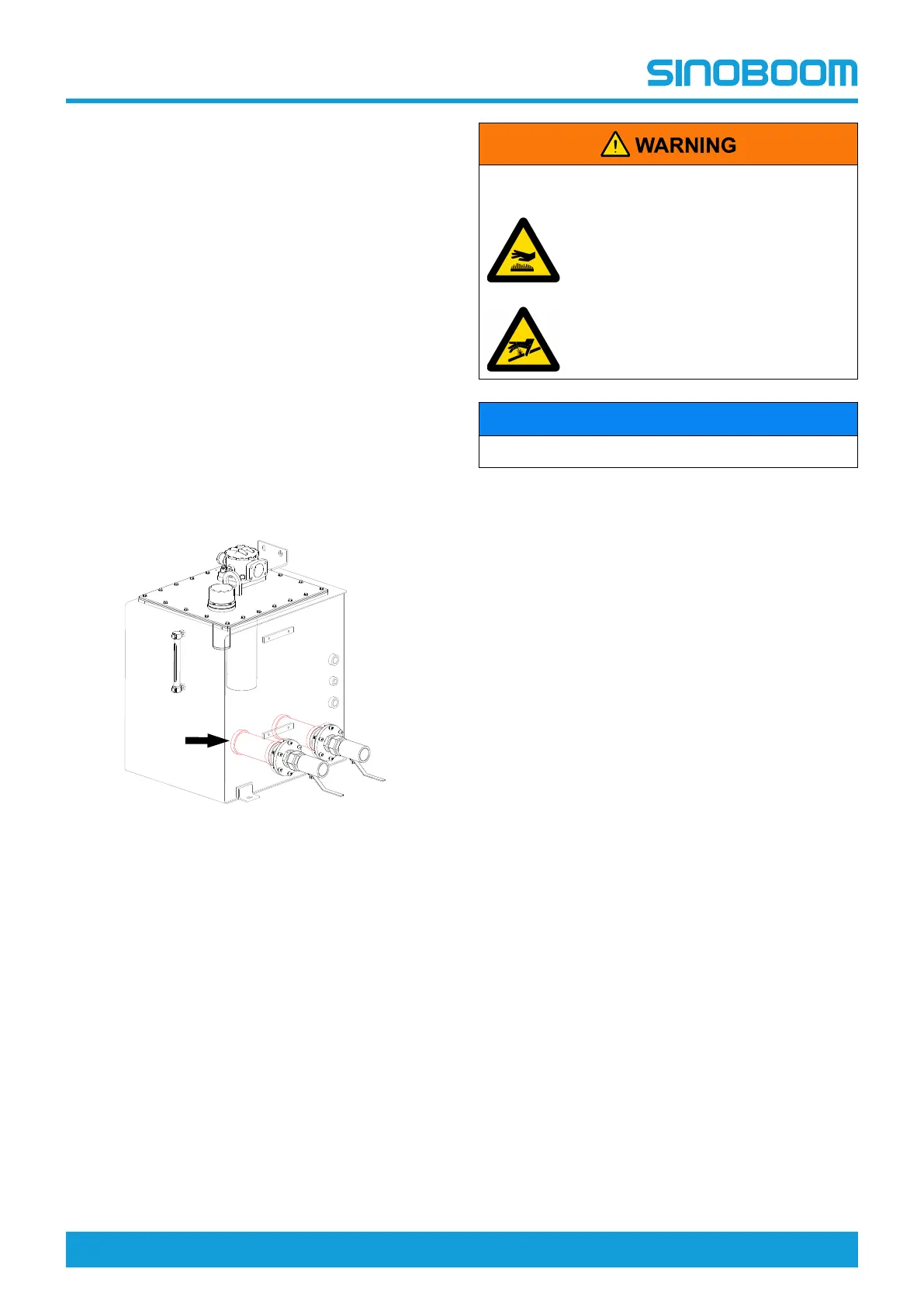

D-4 Replace Hydraulic Tank Suction

Filter

Regularly replacing hydraulic tank suction filter is vital

to good machine performance and extending service

life. Dirty hydraulic oil may cause the machine to

function improperly and continued use may result in

hydraulic component damage. Extremely dirty condition

requires the oil changes to be performed more

frequently.

When performing the procedure D-3 Replace

Hydraulic Oil, page 5-35, the hydraulic tank suction

filter must also be replaced.

Figure 5-53

D-5 Replace Coolant and Coolant

Hoses (water-cooled engine)

Regularly replacing the coolant and coolant hoses is

vital to good engine performance and extending service

life. Unqualified cleanliness coolant may cause the

machine to function improperly and continued use

could result in hydraulic component damage. Extremely

harsh condition requires the coolant changes to be

performed more frequently.

BURN AND HIGH PRESSURE

HAZARD

Before replacing the coolant, allow

the fluid in the coolant tank to cool

down to room temperature.

NOTICE

Shut off the engine before inspection.

1. Open the right side cover of turntable, and locate

the coolant tank.

2. Disconnect the the coolant return hose, and drain

the coolant inside the return hsoe into a suitable

vessel.

3. Open the coolant tank cover.

4. Open the coolant tank drain valve to completely

drain the coolant into a suitable vessel.

5. After the coolant is fully drained, close the drain

valve.

6. Remove the coolant hose clamp, and remove the

coolant hoses from each connector.

7. Install the clamp onto the new coolant hose, and

attach the hose to the corresponding connector.

8. Secure the hose clamp in place.

9. Add new coolant into the tank until the coolant level

reaches the fill port of the tank.

10. Clean up the coolant spills in performing the

procedure.

11. Start the engine from the ground controller to

circulate the coolant in the cooling system.

12. Shut off the engine.

D-6 Replace Fuel Hoses

Regularly replacing the fuel hoses is vital to safe engine

operation and extending service life. Long-time use of

old, frayed or broken fuel hoses may pose dangers to

machine operation.

Loading...

Loading...