© Jun 2022 5-24 TB24 Plus&26J Plus Maintenance Manual

MAINTENANCE PROCEDURES

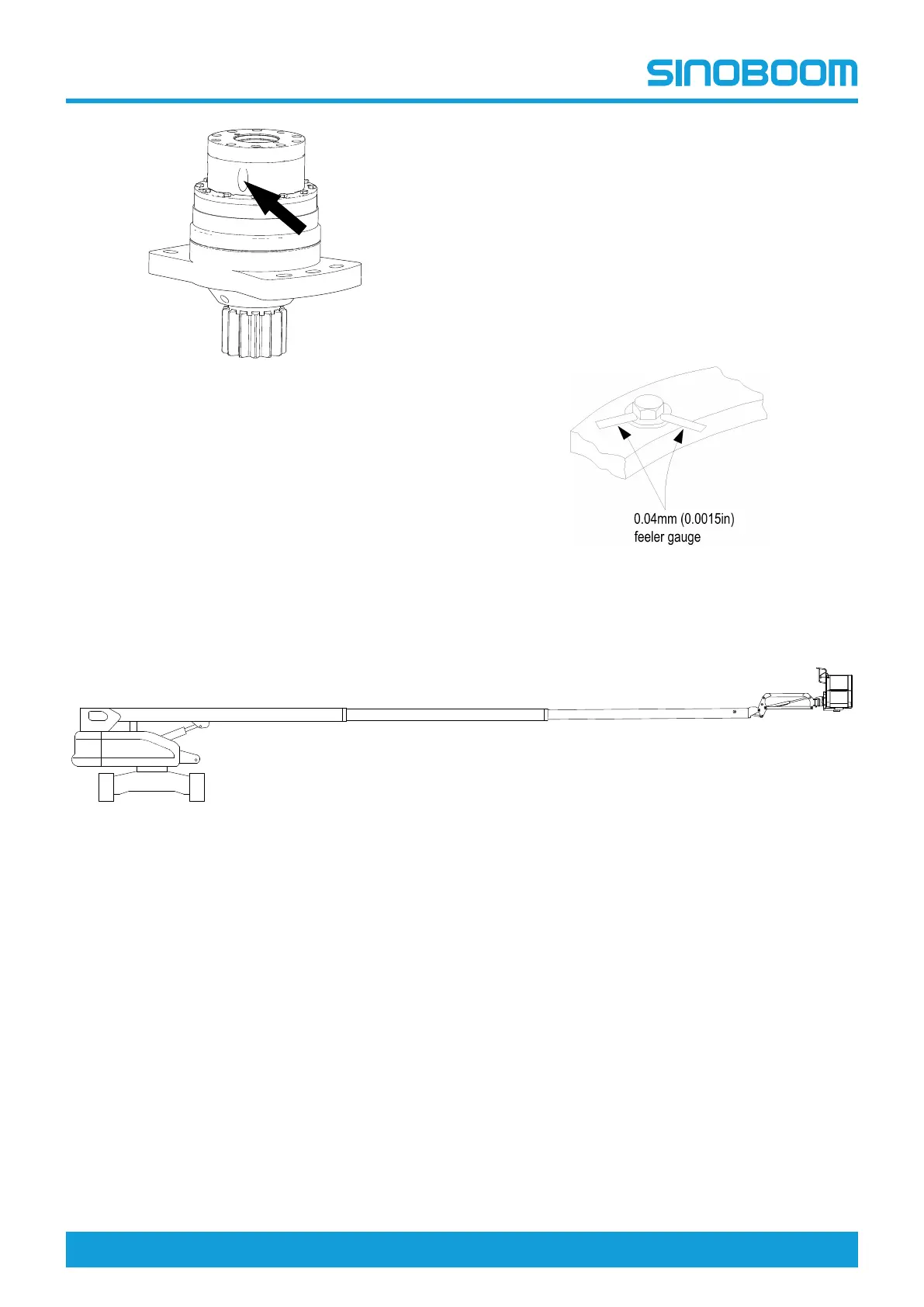

Figure 5-30

1. Open the left side cover of turntable, and locate the

slewing reducer.

2. Remove the plug of fill port to check the oil level.

3. The oil level should be even with the bottom of the

plug hole.

4. If the oil level is lower than the bottom of the plug

hole, add oil.

5. Add gear oil from the fill port until the oil level is

even with the bottom of the plug hole.

6. Install the plug back.

7. Clean up the gear oil spills during the inpection.

B-13 Inspect Slewing Bearing Bolts

Regularly inspecting the slewing bearing bolts is vital to

proper machine operation. This inspection should be

performed after the first 50 hours of operation and

every 600 hours thereafter. If the bolts come off or get

loose, replace with new ones. Apply threadlocker

Loctite 272 to the new bolts and torque to specification.

After the bolts are replaced and torqued, re-inspect the

bolts for tightness.

Figure 5-31

Inspecting the connecting bolts between

chassis and slewing bearing

Figure 5-32

1. Fully extend the boom and raise to horiztzontal

position.

2. Locate the connecting bolts between chassis and

slewing bearing.

3. As indicated by the arrow Fig 5-30 , page 5-24,

insert 0.04mm feeler gauge in between the bolt and

washer.

4. Ensure the feeler gauge won’t go through the

outside of bolt head to the bolt shank.

5. Rotate the turntable to inspect all the bolts.

Inspecting the connecting bolts between

turntable and slewing bearing

Loading...

Loading...