84

6. Commissioning

NOTE

Only fill using clean lubricant and an

appropriate device. Contaminated lubricants

lead to system malfunctions. The lubricant

reservoir must be filled without introducing

bubbles.

NOTE

Different lubricants must not be mixed to-

gether. Doing so can cause damage and

require costly and complicated cleaning of

the product/lubrication system. It is re-

commended that an indication of the

lubricant in use be attached to the lubricant

reservoir in order to prevent accidental

mixing of lubricants.

6.1 General

The described product functions automati-

cally. The lubricant transport in the lubrication

lines should, however, be subjected to regular

visual inspection.

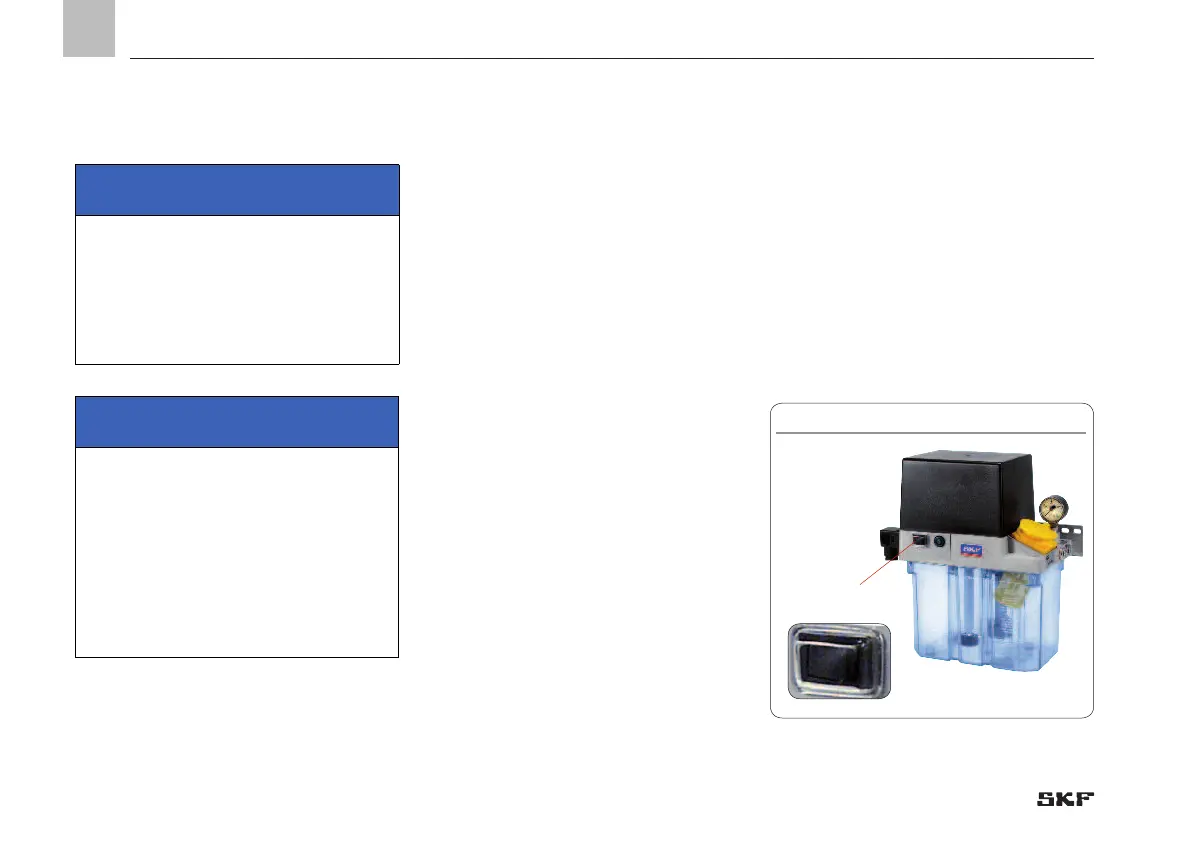

6.2 Interim lubrication pushbutton

The gear pump unit can optionally be equip-

ped with a pushbutton (1) (DK) for manually

triggering an interim lubrication. This is

often used when performing setup work on

the machine/system. The gear pump unit

delivers lubricant as long as the pushbutton

remains pressed.

MKU gear pump unit, Fig. 4

1

Cover cap

EN

6. Commissioning

DK

pushbutton

Loading...

Loading...