96

Section 5 – Procedures Wheel Reinstallation and Torquing Procedure

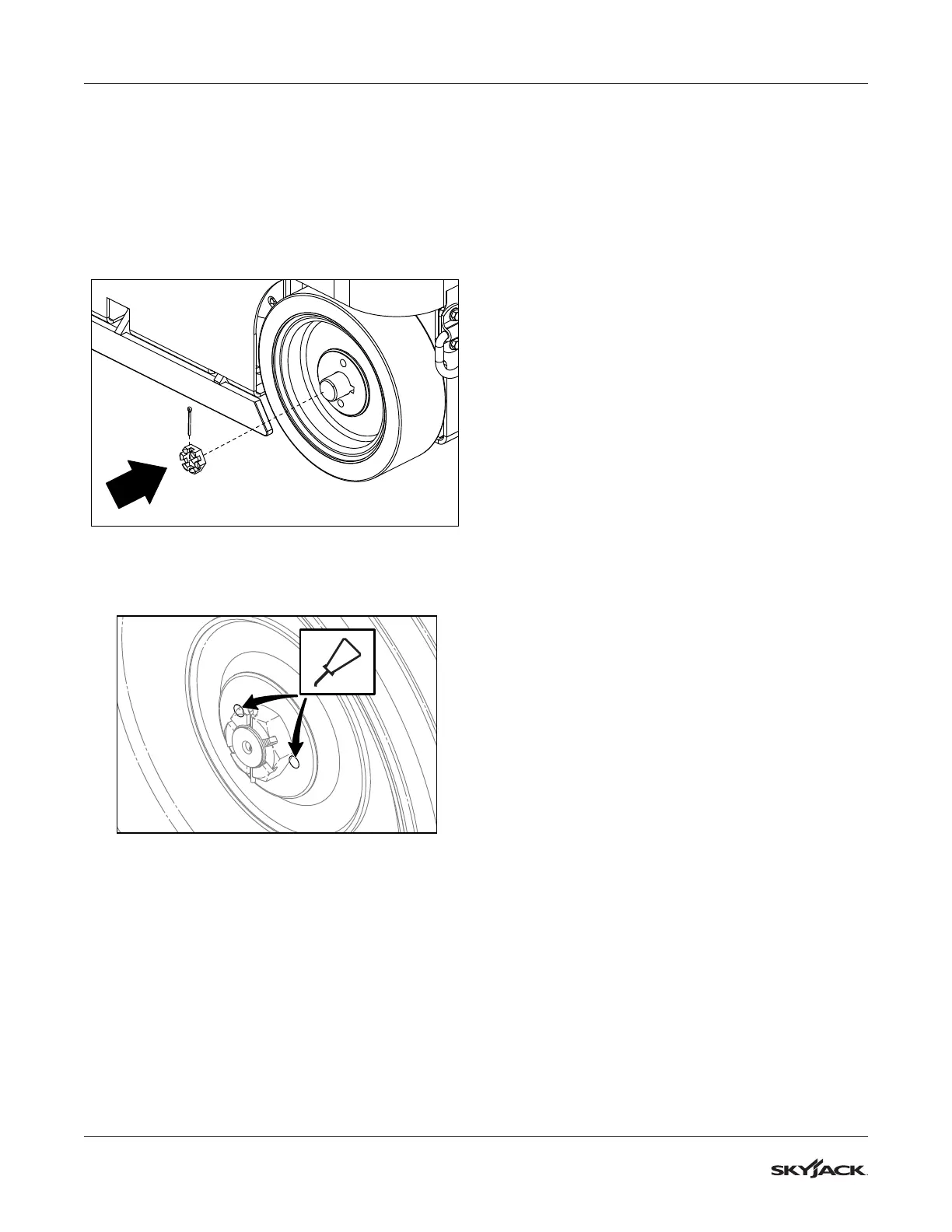

6. Use a torque wrench to tighten the castle nut to

95 Nm ( 70 ft-lb ) and insert the cotter pin.

7. If the holes do not align to install the cotter pin,

continue to torque the castle nut clockwise until

the next hole is visible.

8. Make sure the cotter pin is pushed in completely.

9. Bend the ends of the cotter pin to secure the

castle nut.

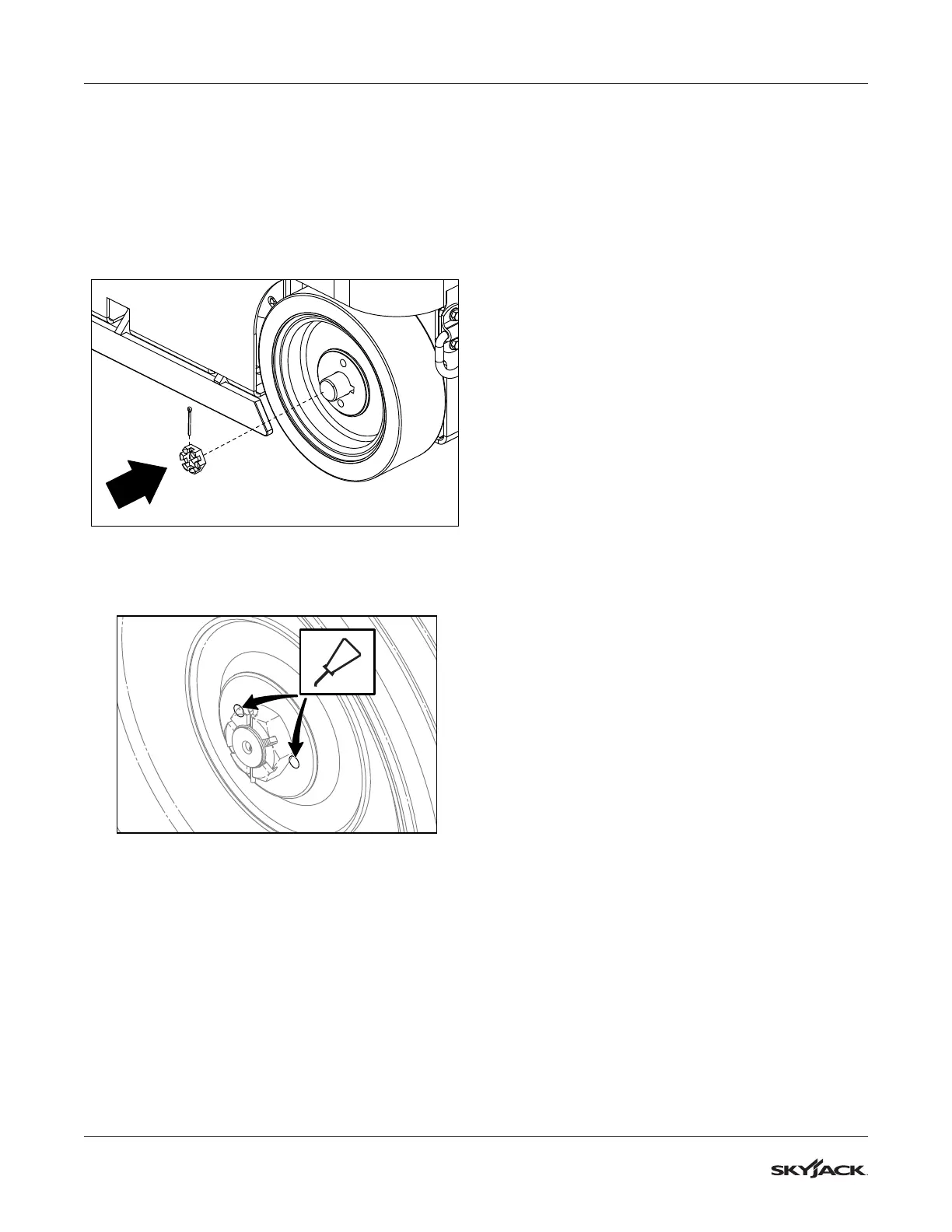

10. To limit rust bleed, it is recommended that a

few drops of grease be applied to the two small

tapped holes on the front wheels.

Loading...

Loading...