23

Mast inspections Section 1 – Scheduled Maintenance

1.7 Mast inspections

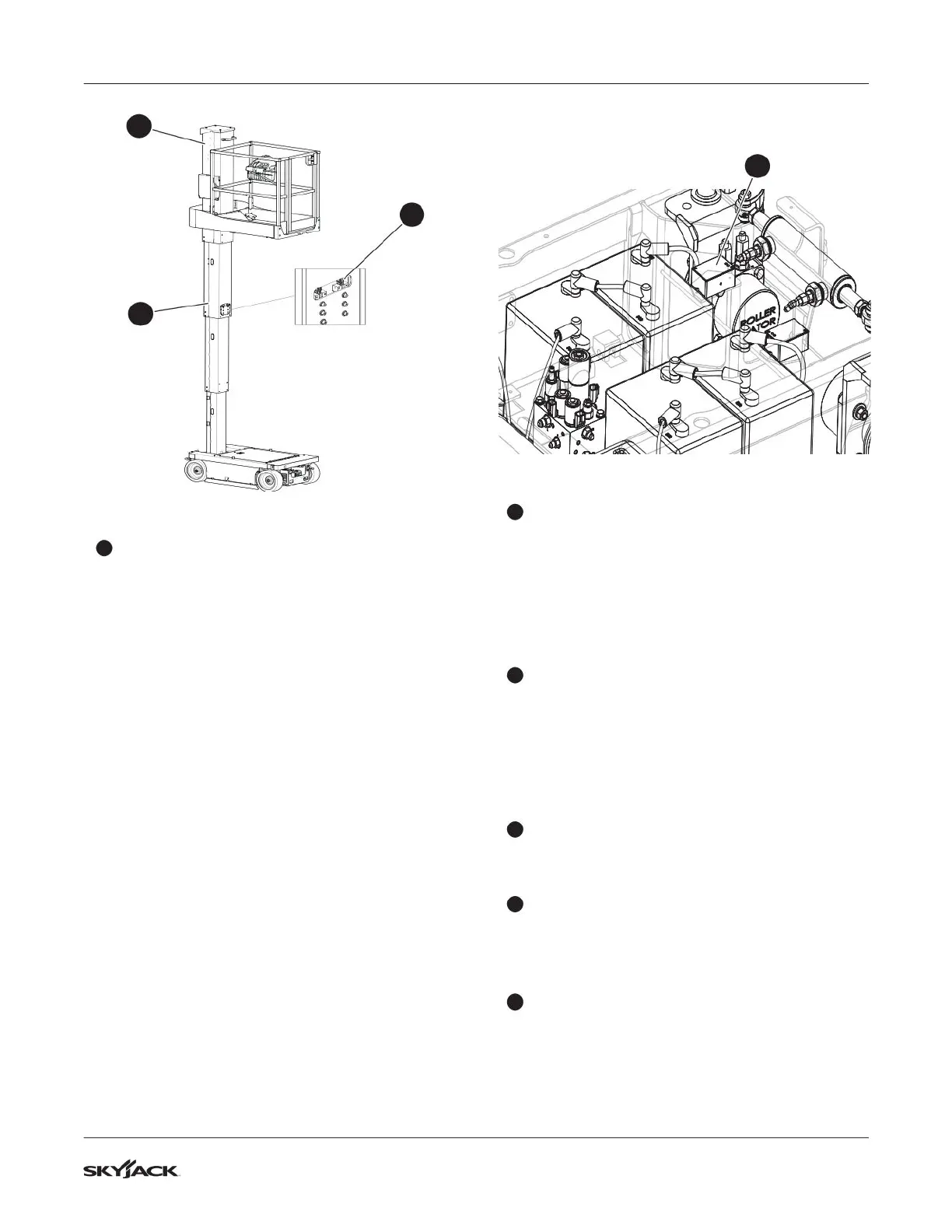

1

Mast assembly (B, C)

▪

B - Frequent/periodic/pre-delivery Inspection

▪

Make sure the mast assembly shows no signs

of visible damage, deformation, or cracks in

the weldments.

▪

Make sure the lift cylinder is properly secured,

there are no loose or missing parts and there

is no sign of damage.

▪

Make sure there are no loose or missing

fittings and there is no sign of hydraulic leaks.

▪

Mast lubrication is an annual requirement as

a minimum. Based on machine use, the mast

may need to be lubricated more frequently.

Examples include:

▪

It is used in very dusty environments.

▪

The mast does not move freely.

▪

Refer to 5.8 Mast Lubrication Procedure for the

mast lubrication procedure.

▪

C - Annual Inspection

▪

Lubricate the mast.

▪

Refer to 5.9 Mast Lubrication Procedure for the

mast lubrication procedure.

2

Chains (C)

▪

Make sure the chains are correctly attached.

▪

Make sure the bolts are tight.

▪

Make sure there are no loose or missing parts.

▪

Make sure there is no visible damage.

▪

Refer to 5.11 Mast Chain Visual Inspection for a

mast chain inspection.

3

Rollers (B)

▪

Make sure the rollers are correctly attached and

not obstructed.

▪

Make sure there are no loose or missing parts.

▪

Refer to 5.10 Mast Roller Inspection/Maintenance

for roller and roller mount inspection details and

instructions.

4

Control Cables (B)

▪

Make sure the cables are secure.

▪

Make sure there is no visible damage.

5

Wear Pads (B)

▪

Make sure the bolts are tight.

▪

Make sure there are no loose or missing parts.

▪

Make sure there is no visible damage.

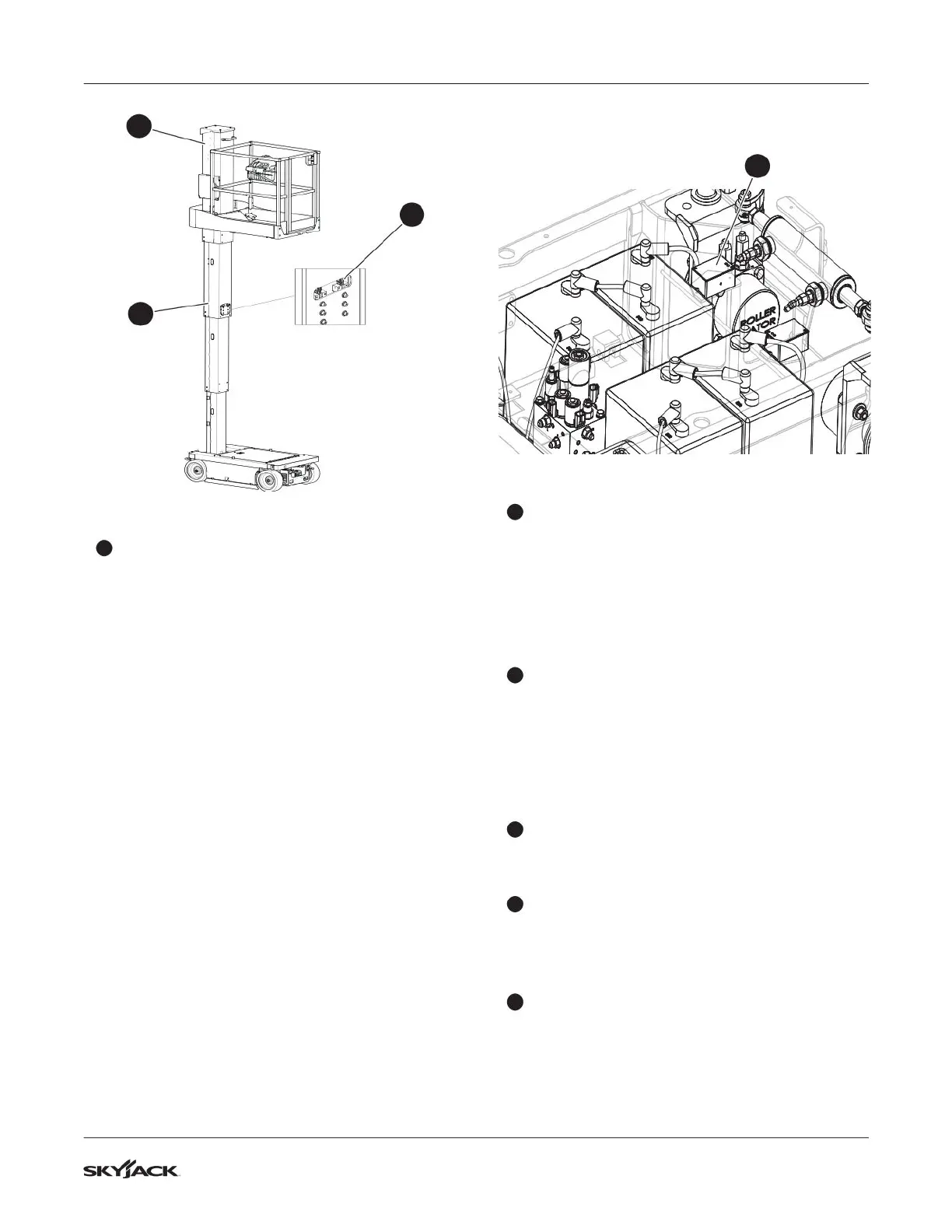

6

Tilt sensor (B)

▪

Make sure the tilt sensors are correctly

attached and there is no visible damage.

1

5

2

6

Loading...

Loading...