22

Section 1 – Scheduled Maintenance Base inspections

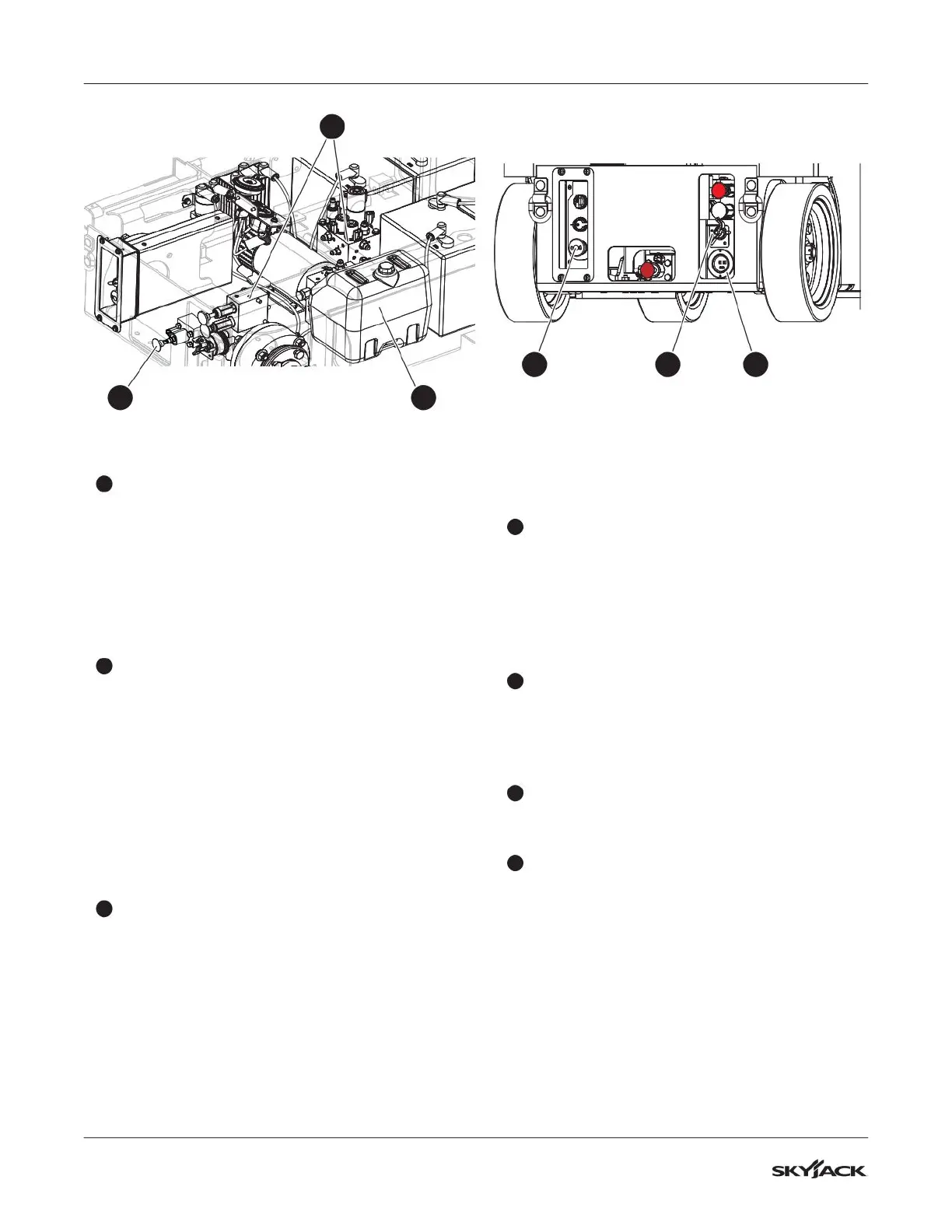

9

Hydraulic tank (B)

▪

Make sure the hydraulic filler cap closes tightly.

▪

Make sure there is no visible damage or

hydraulic leaks.

▪

Hydraulic pump and motor (B)

▪

Make sure there are no loose or missing

fasteners.

▪

Make sure there is no visible damage.

10

Hydraulic oil level (B, C)

▪

B - Frequent/periodic/pre-delivery Inspection

▪

Make sure the platform is fully lowered.

▪

Do a check on the gauge on the side of the

hydraulic oil tank. The hydraulic oil level must

be at or a small distance above the top mark

of the gauge.

▪

C - Annual Inspection

▪

Do a check on the hydraulic oil and filters

▪

Replace the hydraulic oil and filters if

necessary.

11

Electrical components (B)

▪

Do a check on these areas for chafed, corroded,

and loose wires:

▪

Base to platform cables and wiring harness

▪

Hydraulic and electrical compartment wiring

harnesses.

▪

Motor controller (B)

▪

Make sure the motor controller has no damage

and is correctly attached.

▪

Make sure there are no loose wires or missing

fasteners.

12

Manifolds (B)

▪

Make sure all fittings and hoses are correctly

tightened.

▪

Make sure there is no indication of hydraulic

leakage.

▪

Make sure there are no loose wires or missing

fasteners.

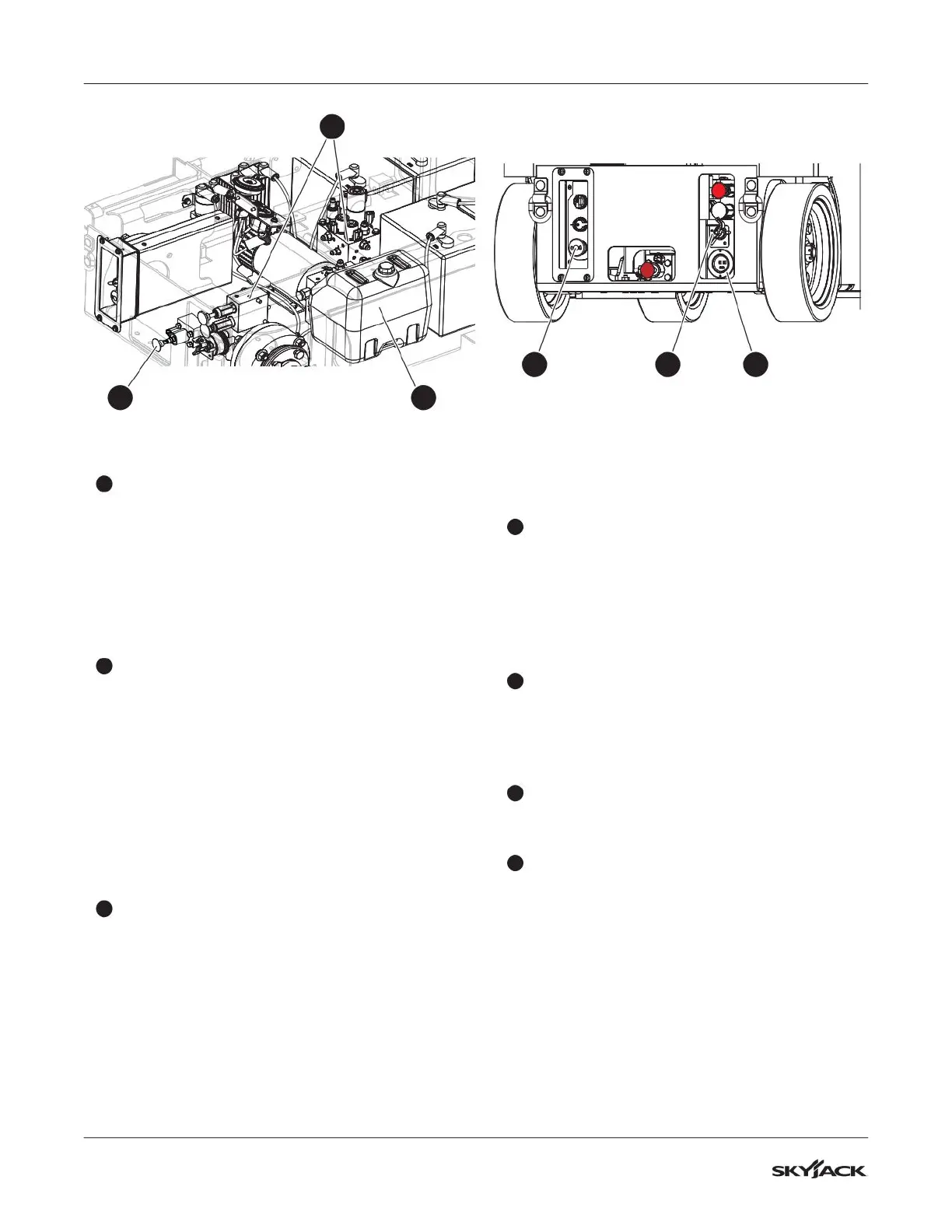

13

Main Power Disconnect Switch (B)

▪

Turn main power disconnect switch to off

position.

▪

Make sure all cables are secure and switch is in

proper working condition.

14

Base Controls (B)

▪

Make sure there are no signs of visible damage

and all switches operate correctly.

15

AC power socket (B)

▪

Make sure there is no visible damage.

12

1314

12

15

9

Loading...

Loading...