21

Base inspections Section 1 – Scheduled Maintenance

▪

B - Frequent/periodic/pre-delivery inspection

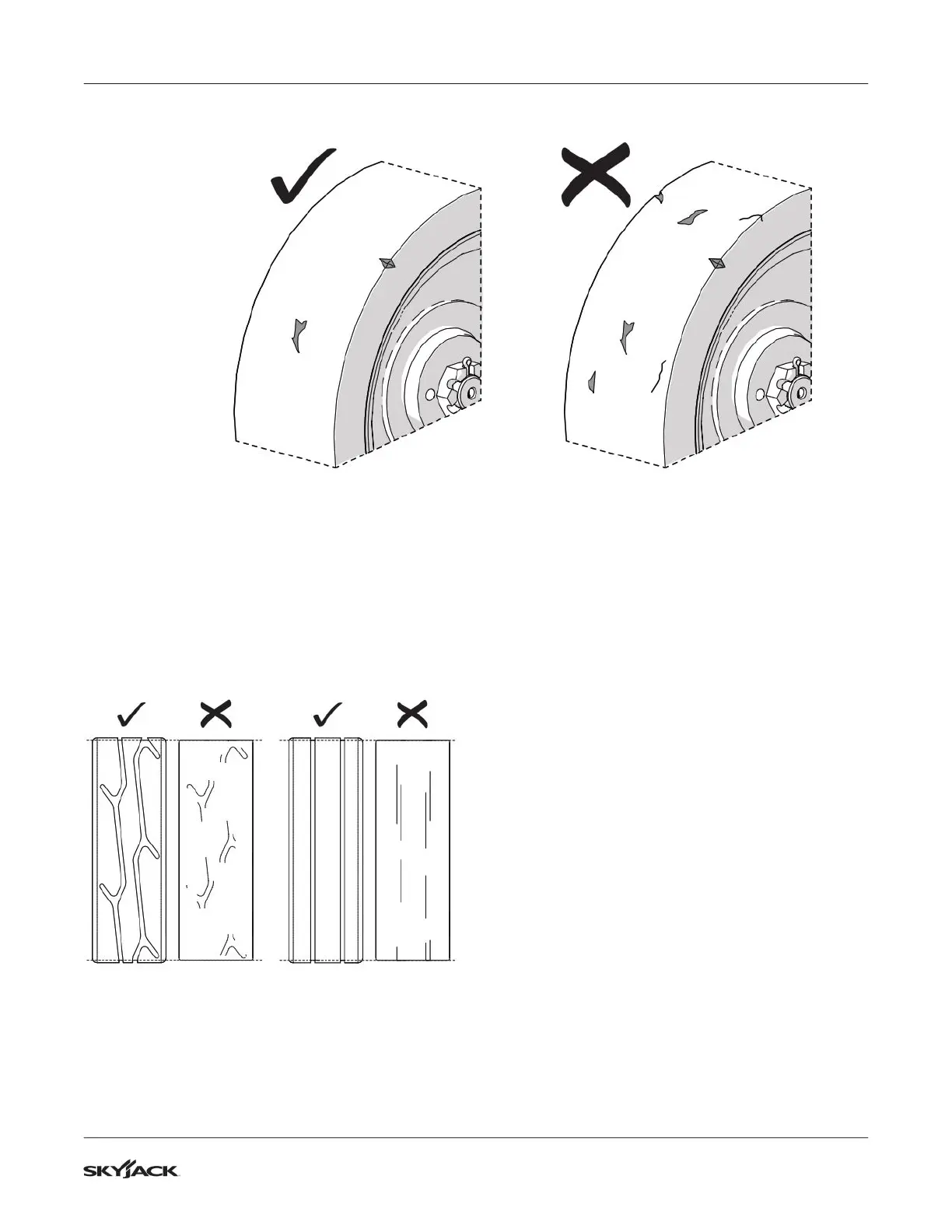

Do a check for damage or wear on each tire and rim.

▪

Look for damage or cracked welds on each rim.

The rims should be round.

▪

Look for uneven or unusual wear on the tire.

▪

Look for flat spots on the tread face of the tire.

▪

The tire tread should be visible and not worn

down completely. Refer to Figure 02.

Figure 02

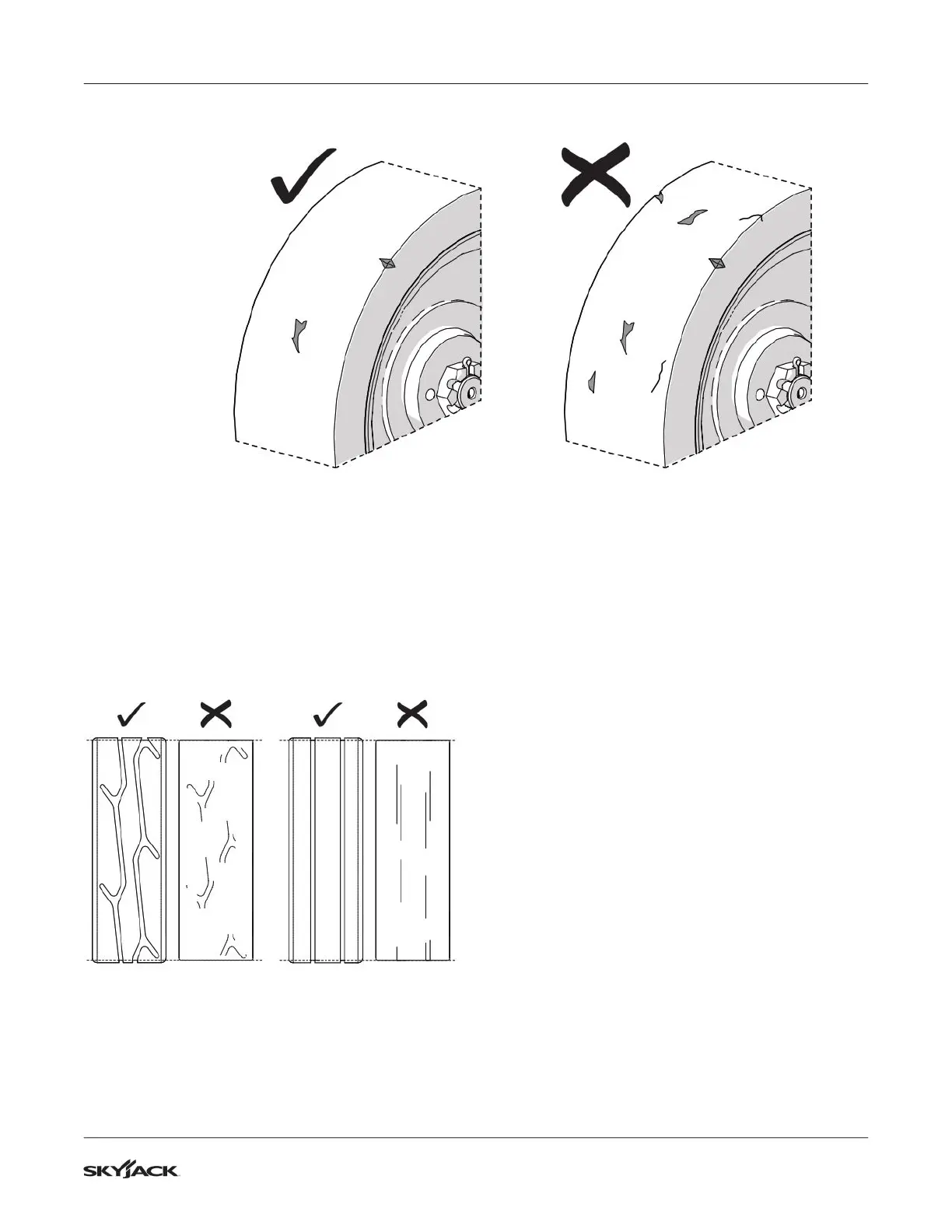

Do a check for cuts or missing chunks in the edges

and tread face of the tire. Refer to Figure 03.

▪

The cut or missing chunk must not extend

more than 10 mm (3/8”) towards the centre of

the tire.

▪

Each cut or chunk should not be larger than

25 mm x 10 mm (1” x 3/8”), or deeper than

20 mm (3/4”).

▪

There should be no more than 2 cuts or

chunks in each 1/4 section of the tire. There

must be no more than 6 cuts or chunks in total

in the tire.

▪

There should be no embedded debris.

Do a check of the wheel components and mounts.

▪

Make sure the wheels are correctly aligned

vertically and horizontally.

▪

Make sure the wheel motors have no loose or

missing parts and there is no visible damage.

▪

C - Annual inspection

▪

Make sure the castle nut is in position and is

tight.

▪

Make sure the cotter pin is correctly installed.

▪

If the cotter pin is not installed, refer to 2.8

Torque Specifications for proper torque

information.

Figure 03

The tire treads have

been removed from the

illustration for clarity.

Loading...

Loading...