95

Wheel Reinstallation and Torquing Procedure Section 5 – Procedures

5.5 Wheel Reinstallation and

Torquing Procedure

Tools Needed

▪

Adjustable Torque Wrench

Capacity 380 Nm (280 ft-lb)

▪

Hub Puller

Hub/Integrated Hub Wheel Removal

1. Use an appropriately rated lifting device to raise

up the MEWP until all the wheels are off the

ground. Set the MEWP on stands adequately

rated to support the weight of the machine.

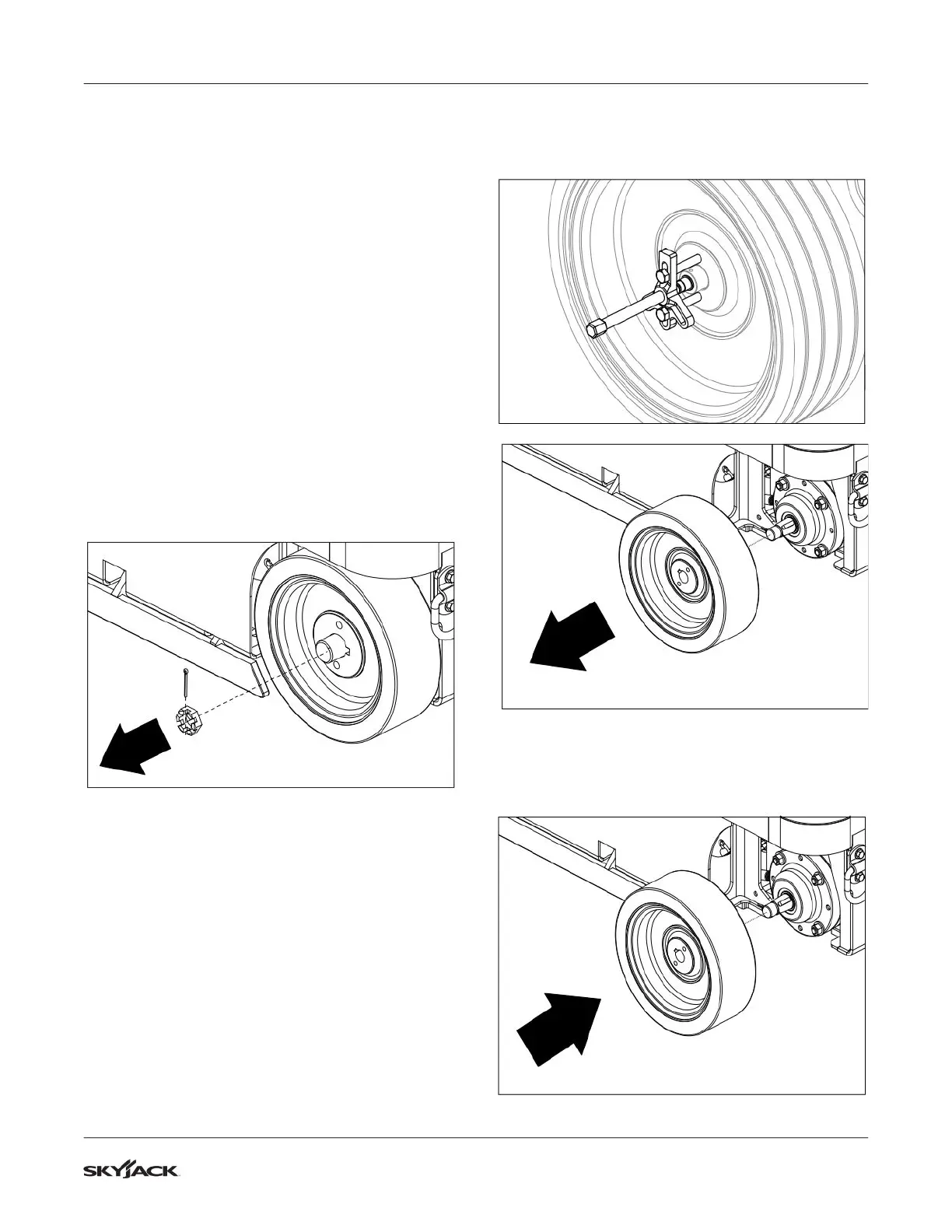

2. Remove and set aside the castle nut.

3. Remove and discard the cotter pin. A new one

will be required for re- installating the integrated

hub wheel.

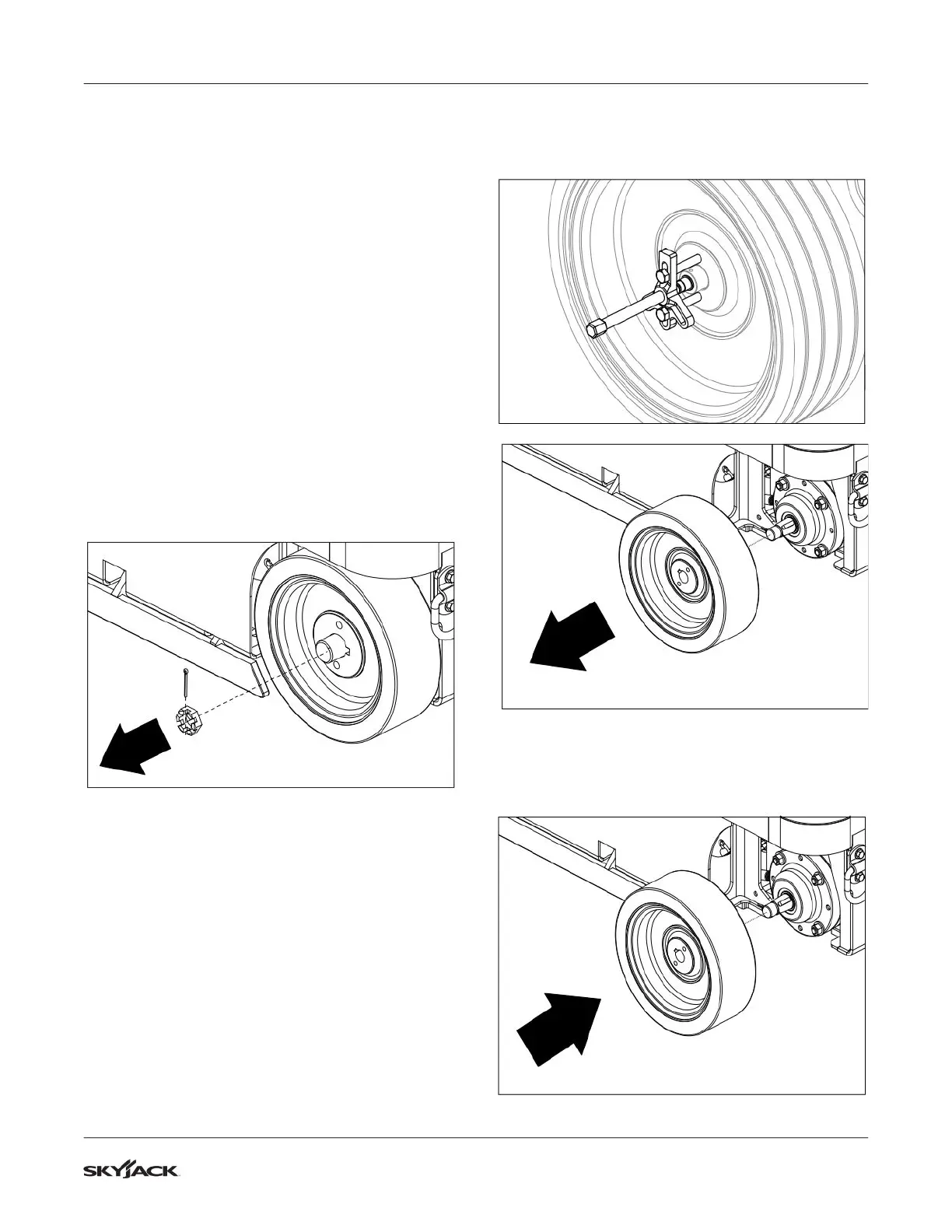

4. Use two 3/8”-24 bolts with a hub puller to

remove the wheel.

5. Install the wheel onto the brake.

Loading...

Loading...