SWDE200B Operation & Maintenance Manual

7.5 ROTARY HEAD

Before mounting to the main machine, do not contact with rainwater. Don not throw away

the packing bag provided by the manufacturer.

If the machine temperature reaches the maximum value 80 ℃ , or the rotary head leakage,

stop the machine and check the sealing ring and the internal structure.

Lubricate all the point in the predefined time, 2#molybdenum disulphide grease is

recommended.

Only the technical personnel who learned the guide book can operate the rotary head.

The maintenance work must comply with relevant

safety regulations. The maintenance work must

comply with relevant safety regulations. Stop the

machine to make sure that the pressure has been

released from the hydraulic system and air

supplying system before assembly and

disassembly.

Operation Maintenance

Check hydraulic circuit joint and hose to make sure

the pipe fittings are tightened.

Make sure that joint and hose are tightened; check

the hose for bending to prevent high pressure gas leakage.

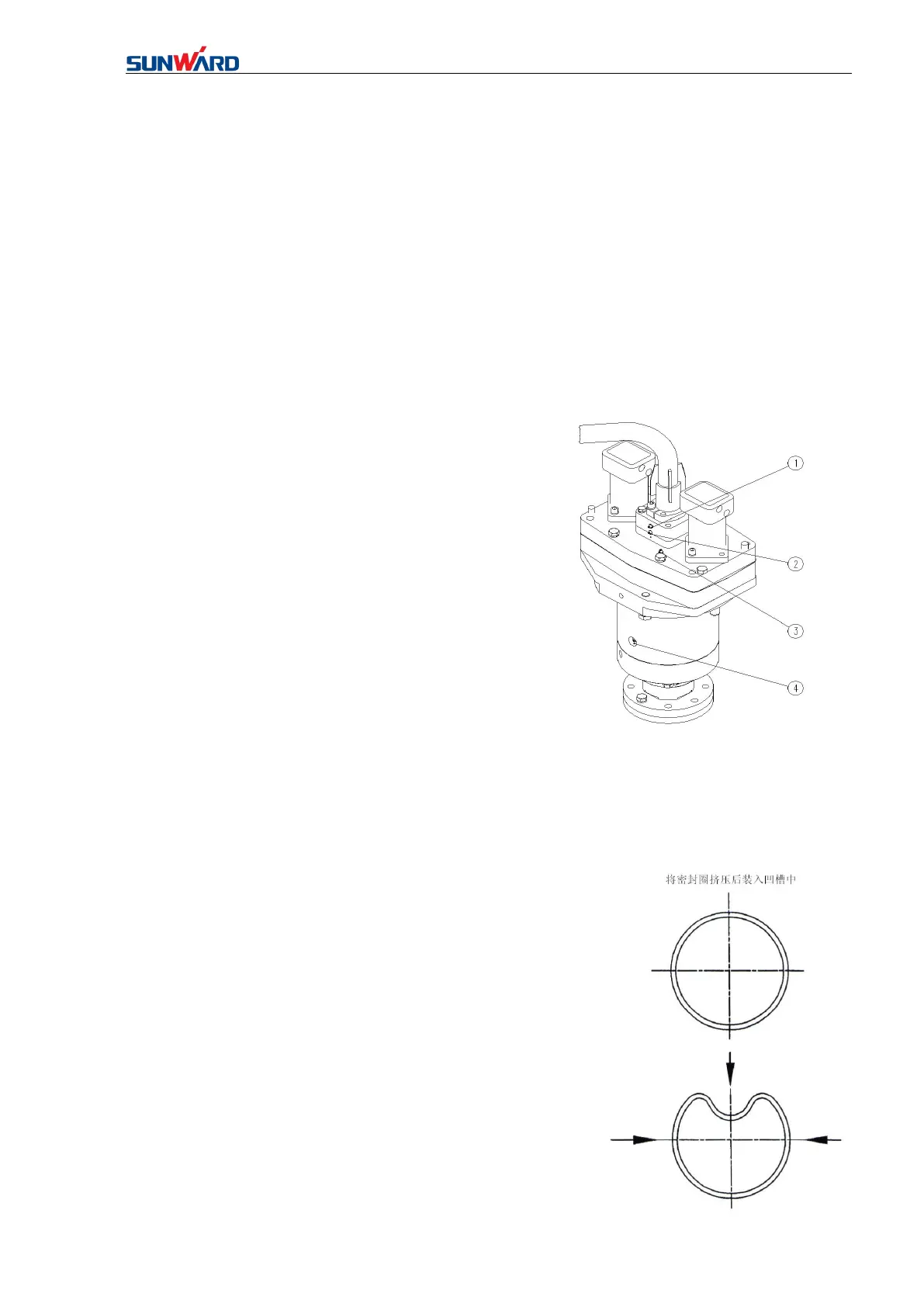

Lubricate the rotary head by using the grease gun, the sealing ring on the air inlet joint

should be lubricated once every 4 hours, every 8 hours for other positions (see the right

figure). Please use the grease recommended by

SUNWARD.

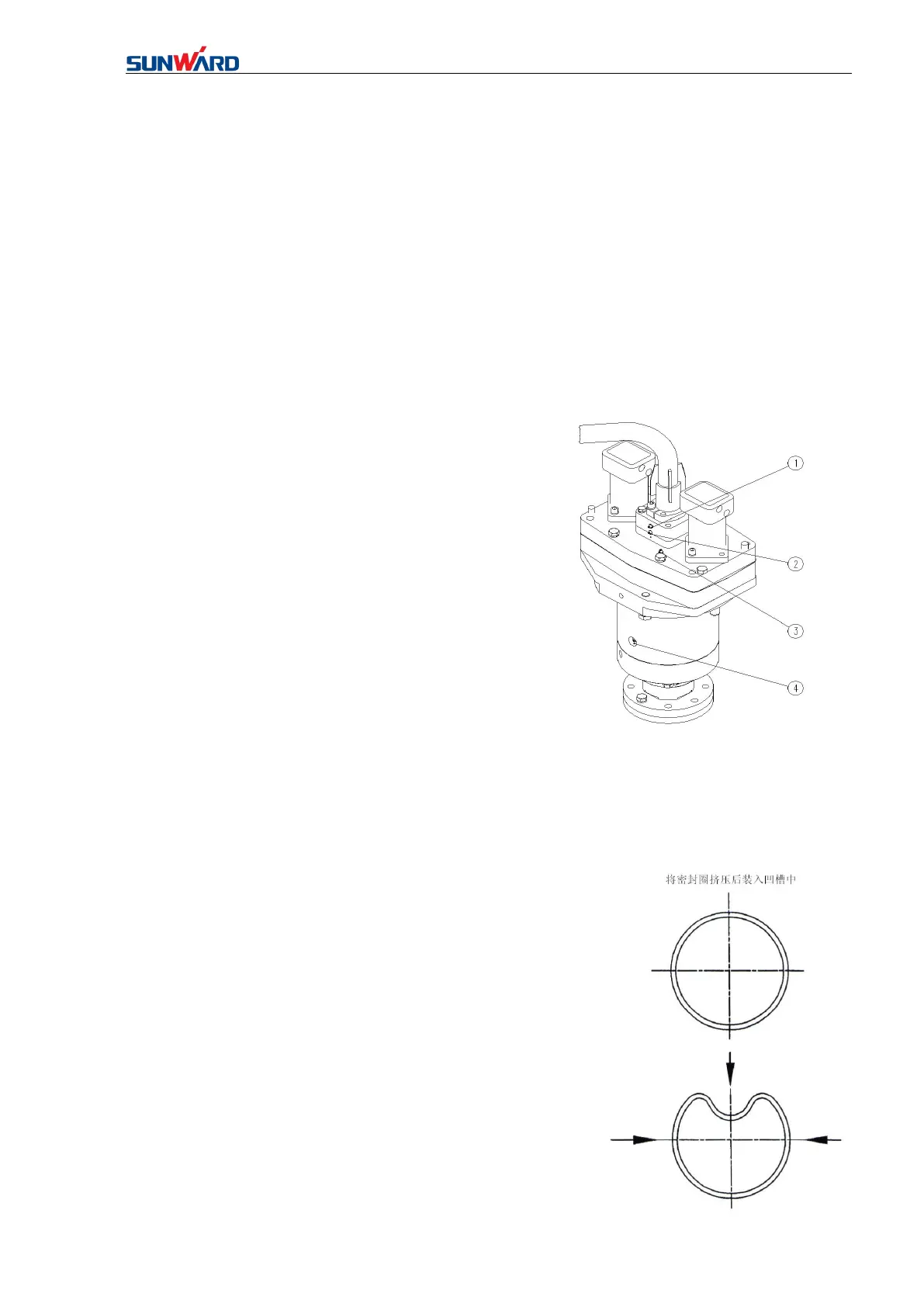

Replace the sealing part of rotary head

The rotary head sealing has an important influence on

performance; it must be lubricated accordance with the

requirement. When the sealing ring wear seriously, it must

be replaced, generally its cycle of replacement is 500hours.

Check sealing groove scratches before assembling. In most

cased, small scratches can be polished with sandpaper. After

all the parts cleaned, the surface coated with grease and then

can install a new seal.

Loading...

Loading...