SWDE200B Operation & Maintenance Manual

Please use the Sunward new original accessories.

The right diagram will show how to squeeze the seal and then install it to the corresponding slot.

Before installation, the sealing surface should be coated with a layer of oil.

Insert into the corresponding groove and install the specified sealing.

As show in the figure, squeeze the sealing ring together.

NOTE: make sure there are no sharp corners, otherwise it will damage the sealing ring and

cause the failure of operation.

Install the sealing ring into the groove, watch and touch with fingers to make sure the correct

installation.

Gently press the sealing ring with a clean round sick or plastic rods to restore the original shape.

Coat the sealing ring with grease and then set it onto the main shaft. Do not knock it hard!

Rotary head inspection

There are heavy load for thread connection on the rotary head, so it should be checked by each

day in the first 50 working hours, check once by week after that period. Please find the

tightening torque in 7.3.

For the initial use of 250 hours to rotary head, the box cover and bottom cover should be

dismantled, the bearing , gear, main shaft should be checked for wearing, round nut, locking

screw should be checked for looseness, and the gap between bearings should be adjusted.

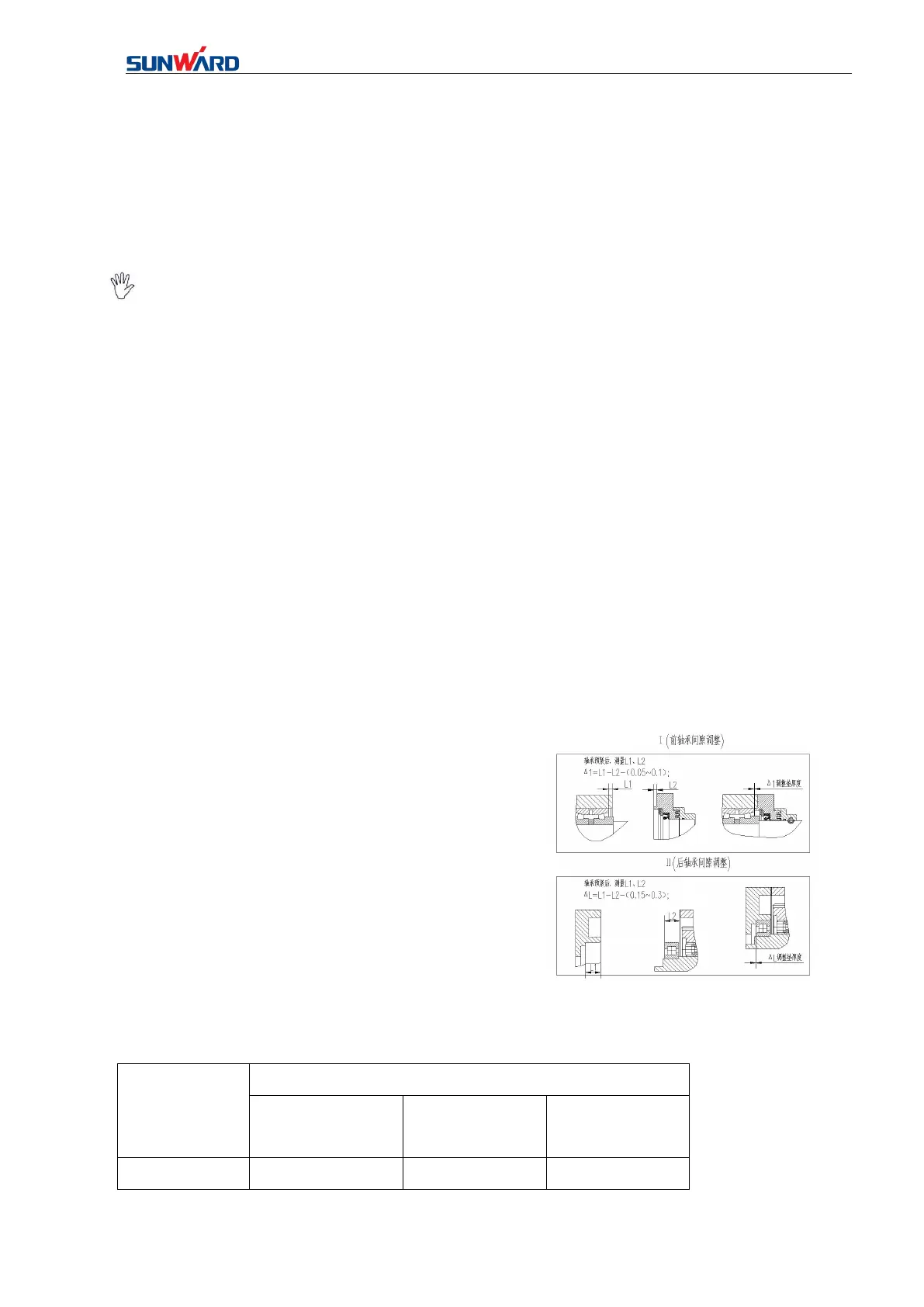

Rotary head assembly

Clean all the parts before assembly;

When assembling the bearing, knock the bearing

inner and outer rings is forbidden (place copper). The

bearing should be close to the shaft shoulder or

sleeve end.

Adjust and fasten bearing, make the bearing has an

axial clearance of 0.05~0.1.

While assembling, locking screw(M10-12.9)should

tightened by three time according to the principle of

diagonal fastening. The tightening torque can be found in following table.

Specification

of Expansion

Sleeve Screw

When assembly, 4~5L gear oil should be injected into the oil tank, and the air inlet oil groove

Loading...

Loading...