7. Cylinder / Piston

7-2

Precautions in Operation

General Information

y Both cylinder and piston service cannot be carried out when engine mounted on frame.

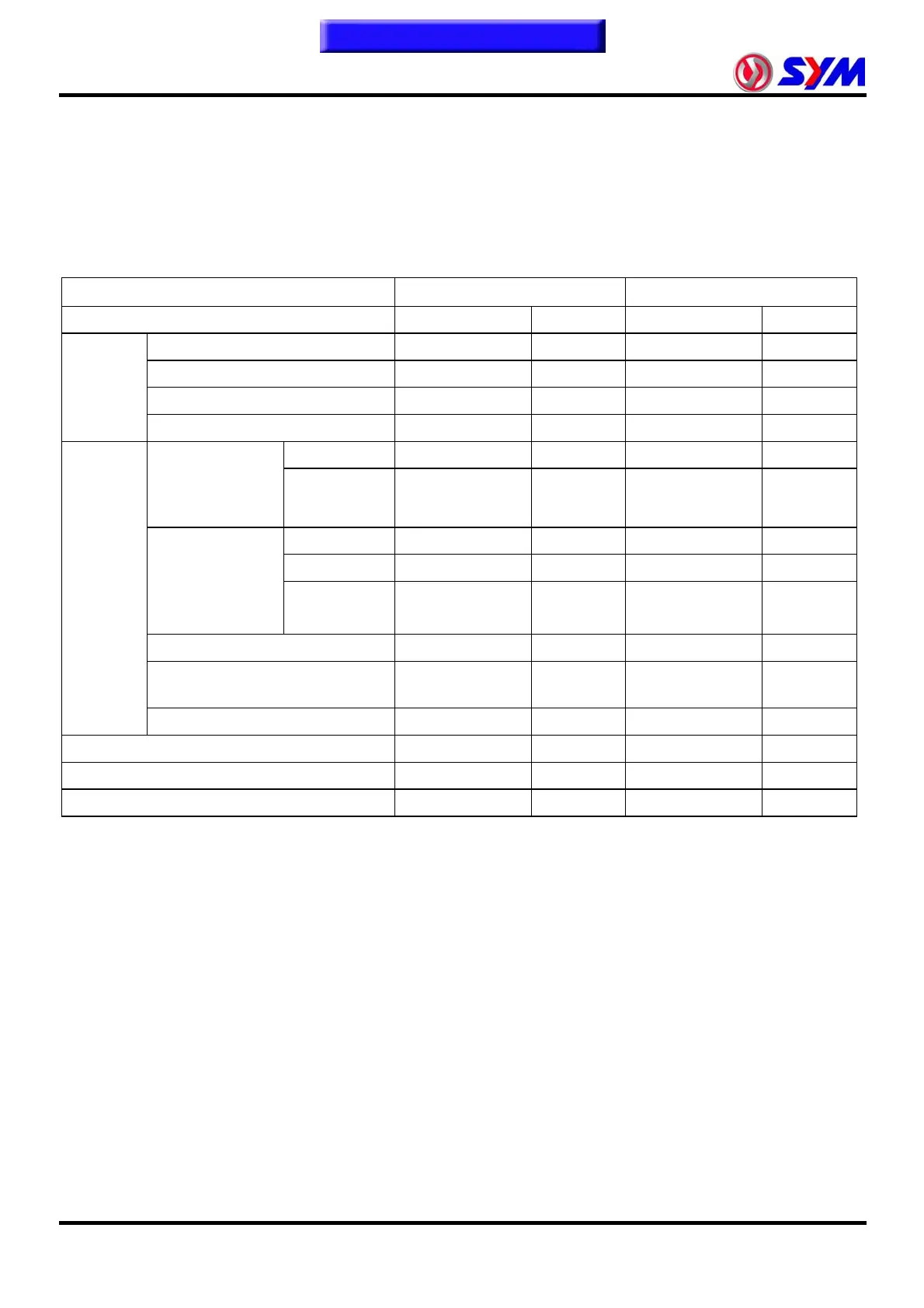

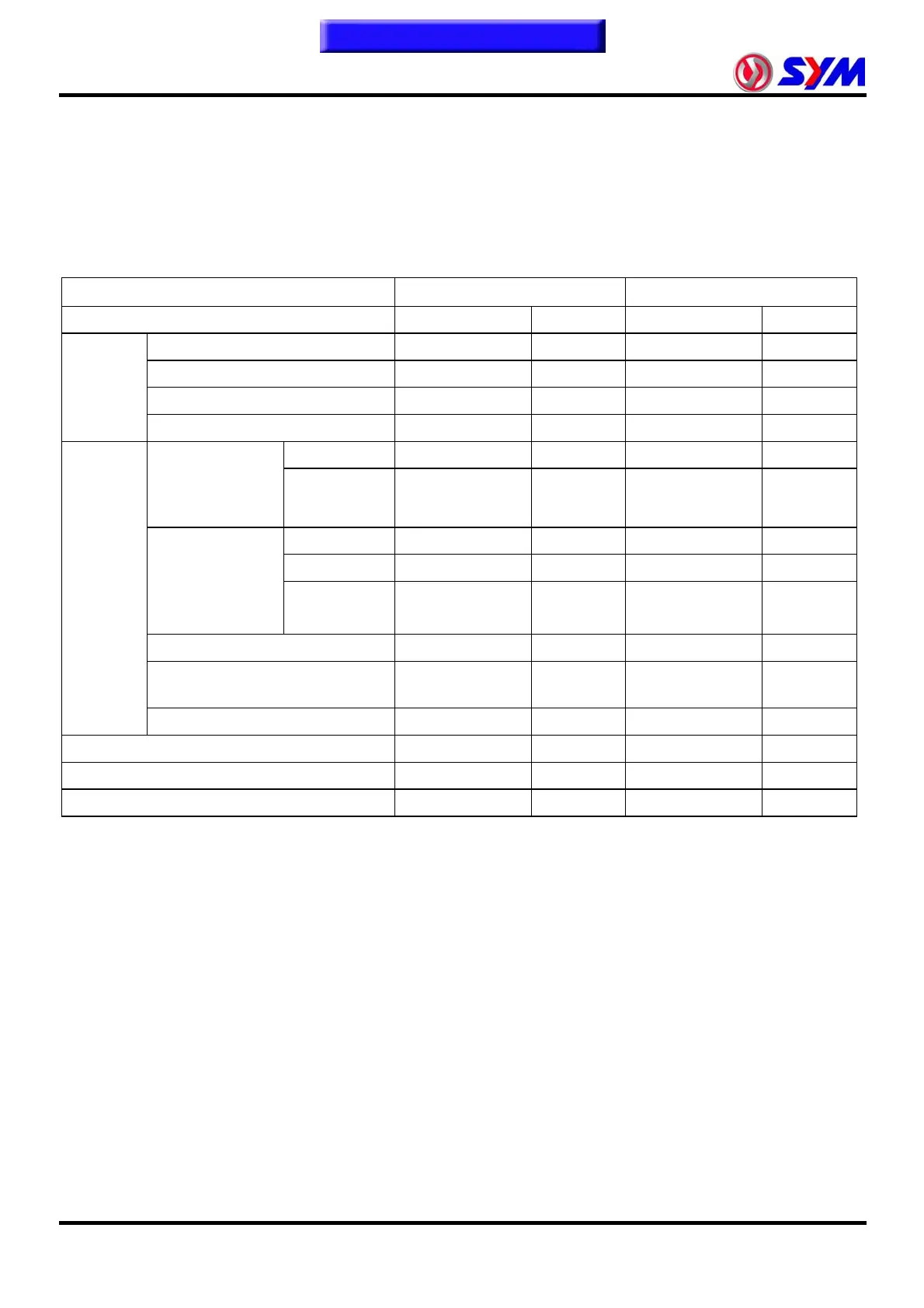

Specification Unit:mm

LM25W5 LM30W

Item Standard Limit Standard Limit

I.D. 70.995~71.015 71.100 72.995~73.015 73.100

Out of round - 0.050 - 0.050

Taper - 0.050 - 0.050

Cylinder

Warpage - 0.050 - 0.050

Top 0.015~0.050 0.090 0.015~0.050 0.090 Clearance

between

piston ring and

ring groove

2

nd

0.015~0.050 0.090 0.015~0.050 0.090

Too 0.150~0.300 0.500 0.150~0.300 0.500

2

nd

0.300~0.450 0.650 0.300~0.450 0.650

Piston ring end

gap

Oil

(side rail)

0.200~0.700 - 0.200~0.700 -

Piston O.D. (2

nd

) 70.430~70.480 70.380 72.430~72.480 72.380

Clearance between piston

and cylinder

0.010~0.040 0.100 0.010~0.040 0.100

Piston/

Piston

ring

ID of piston pin boss 17.002~17.008 17.020 17.002~17.008 17.020

Piston pin O.D. 16.994~17.000 16.960 16.994~17.000 16.960

Clearance between piston and piston pin 0.002~0.014 0.020 0.002~0.014 0.020

Connecting rod small end I.D. 17.016~17.034 17.064 17.016~17.034 17.064

Troubleshooting

Low or Unstable Compression Pressure

y Cylinder or piston ring worn out

Knock or Noise

y Cylinder or piston ring worn out

y Carbon deposits on cylinder head top-side

y Piston pin hole and piston pin wear out

Smoking in Exhaust Pipe

y Piston or piston ring worn out

y Piston ring installation improperly

y Cylinder or piston damage

Engine Overheat

y Carbon deposits on cylinder head top side

y Cooling pipe clogged or not enough in coolant

flow

To this chapter contents

Loading...

Loading...