TRAÇABILITÉ CRÉATIVE

CREATIVE TRACEABILITY

TECHNOMARK

1 Allée du développement 24

42350 La Talaudière (France)

Tel : +33 (0) 4 77 22 25 91

Fax : + 33 (0) 4 77 22 38 93

E-mail : info@technomark-marking.com

V : SJ Le : 20/06/17 R : DD

www.technomark-marking.com

Brackets “[”, “]” and no ASCII characters aren’t allowed in the text. Use the UID codes to add others

characters.

Speed corresponds to the marking speed. Marking speed is different from the rest of the file marking

speed to obtain a quality suitable for code reading.

Code type corresponds to the two dimension code type to create: : Datamatrix STD (datamatrix

standard format), Datamatrix GS1 (datamatrix GS1 format) or QR.

Format corresponds to the code format and depends on the code type selected.

Datamatrix: The code can be automatic (rectangle or square) or at a fixed format selected in

the list.

QR: The code is always square. Its size is automatic or defined by one of the format of the

list.

Format defines the code size (number of elements) but as well the maximum number of characters

than can be encoded.

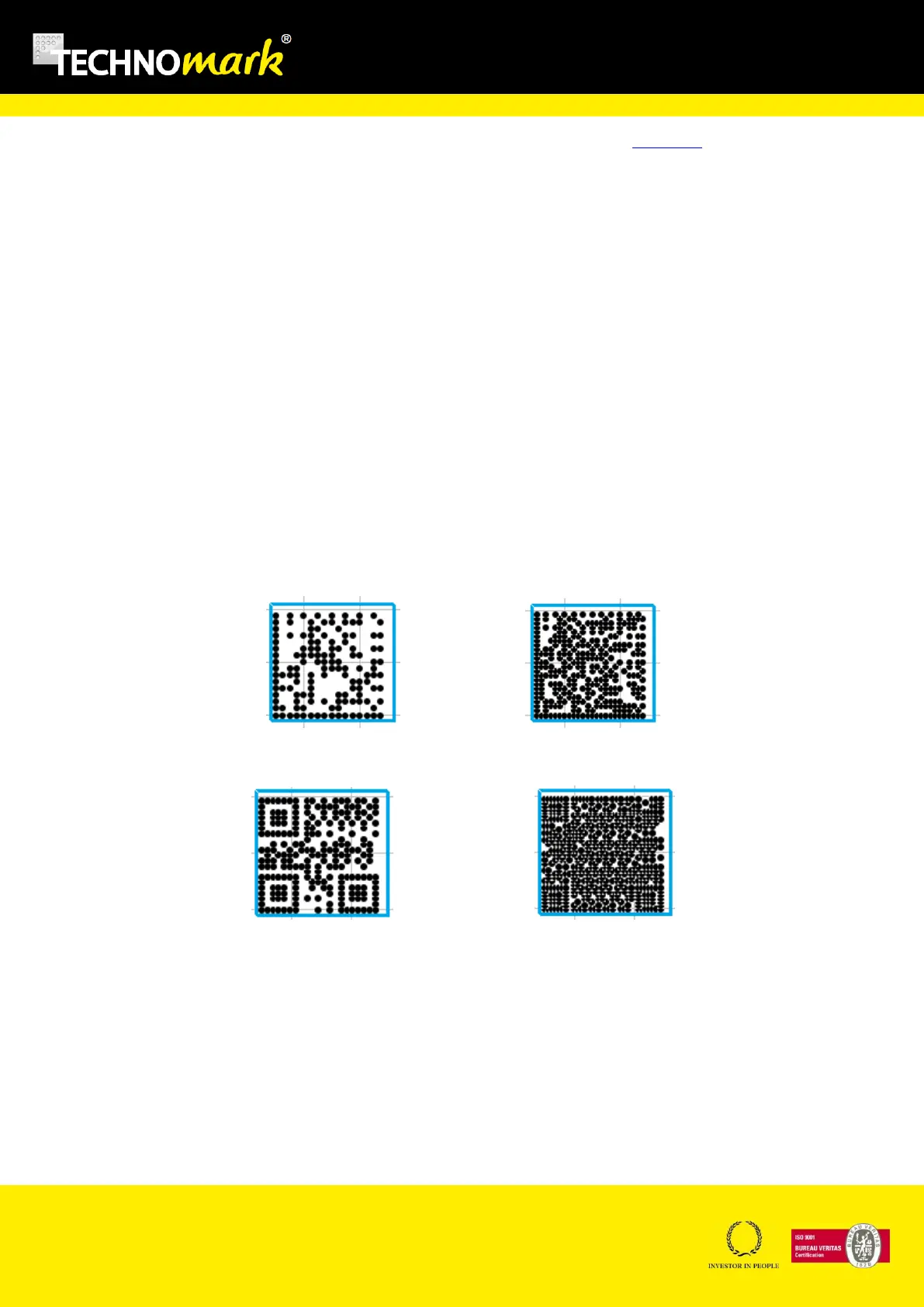

Datamatrix 16x16 Datamatrix 24x24

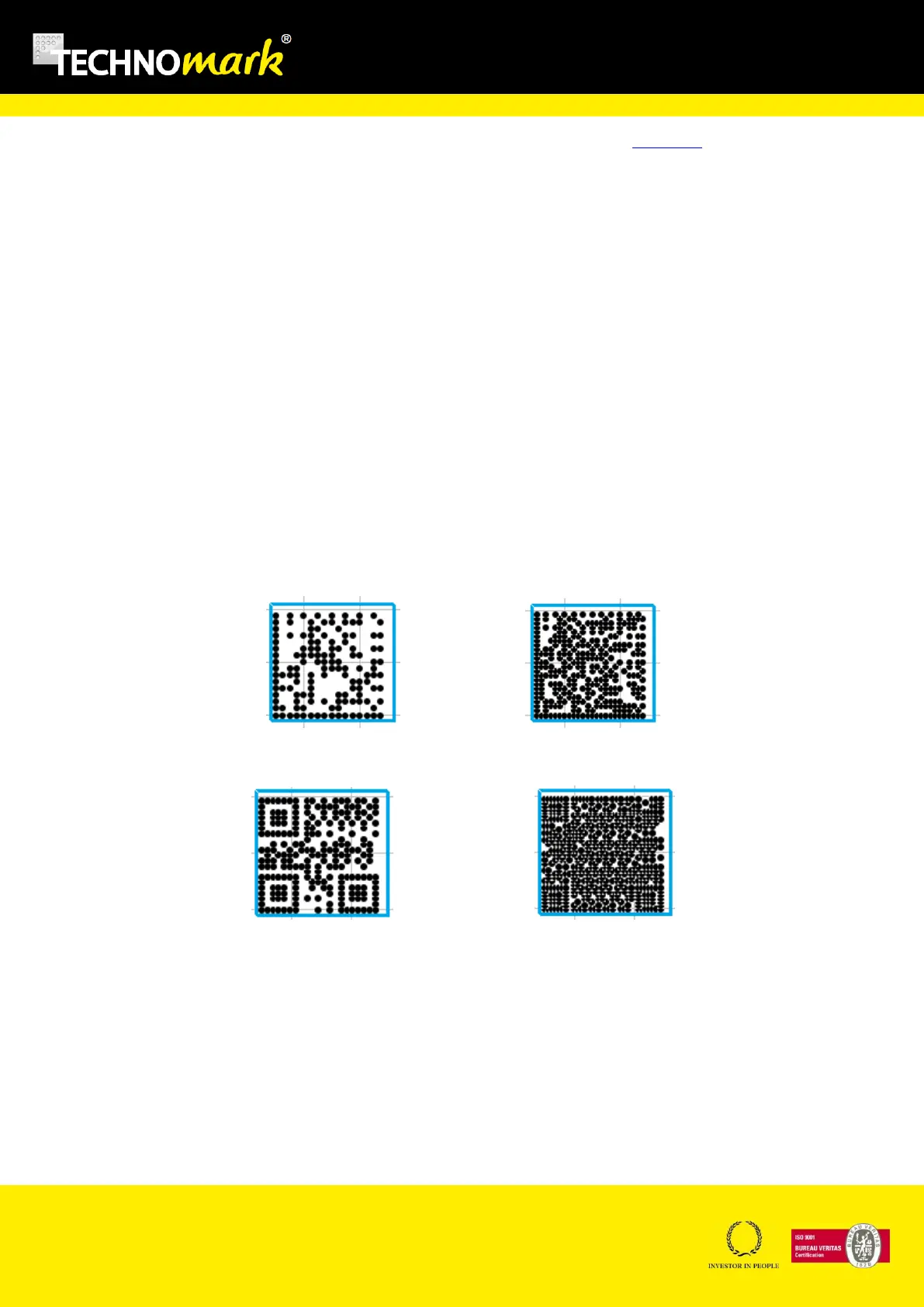

QR 21x21 QR 33x33

Bidirectional corresponds to marking head’s movement. If this parameter is activated, the marking

head will move in both directions on the X or Y axis.

Axis corresponds to the marking axis. By default it will be the X axis.

Auto cell size corresponds to the size of datamatrix cells. If this parameter is activated, the 2D code

size is the same as the line’s height. If this parameter is disabled, the field Value is available.

Loading...

Loading...