EX-TRACK

®

Operator Manual, Revision T-134

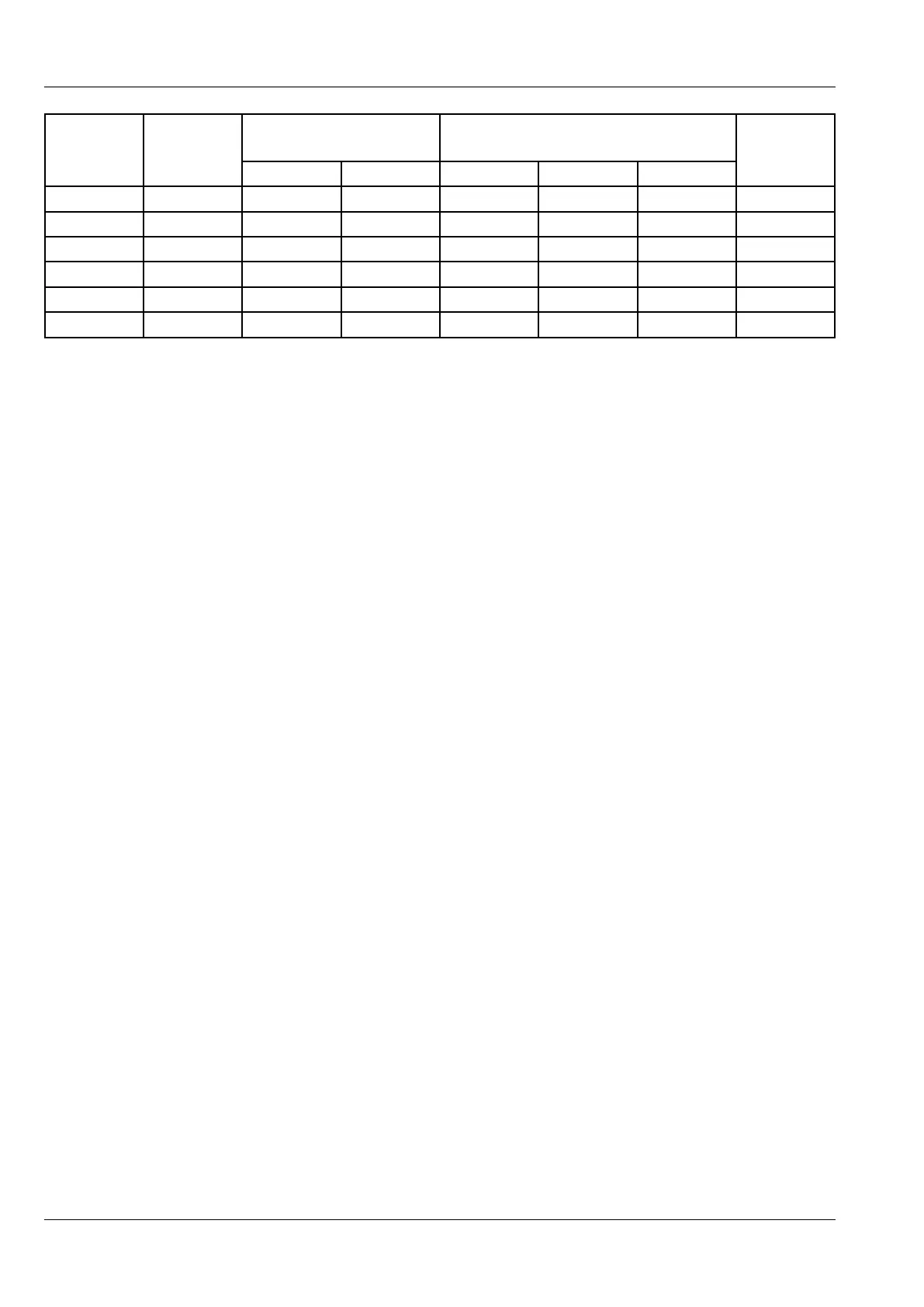

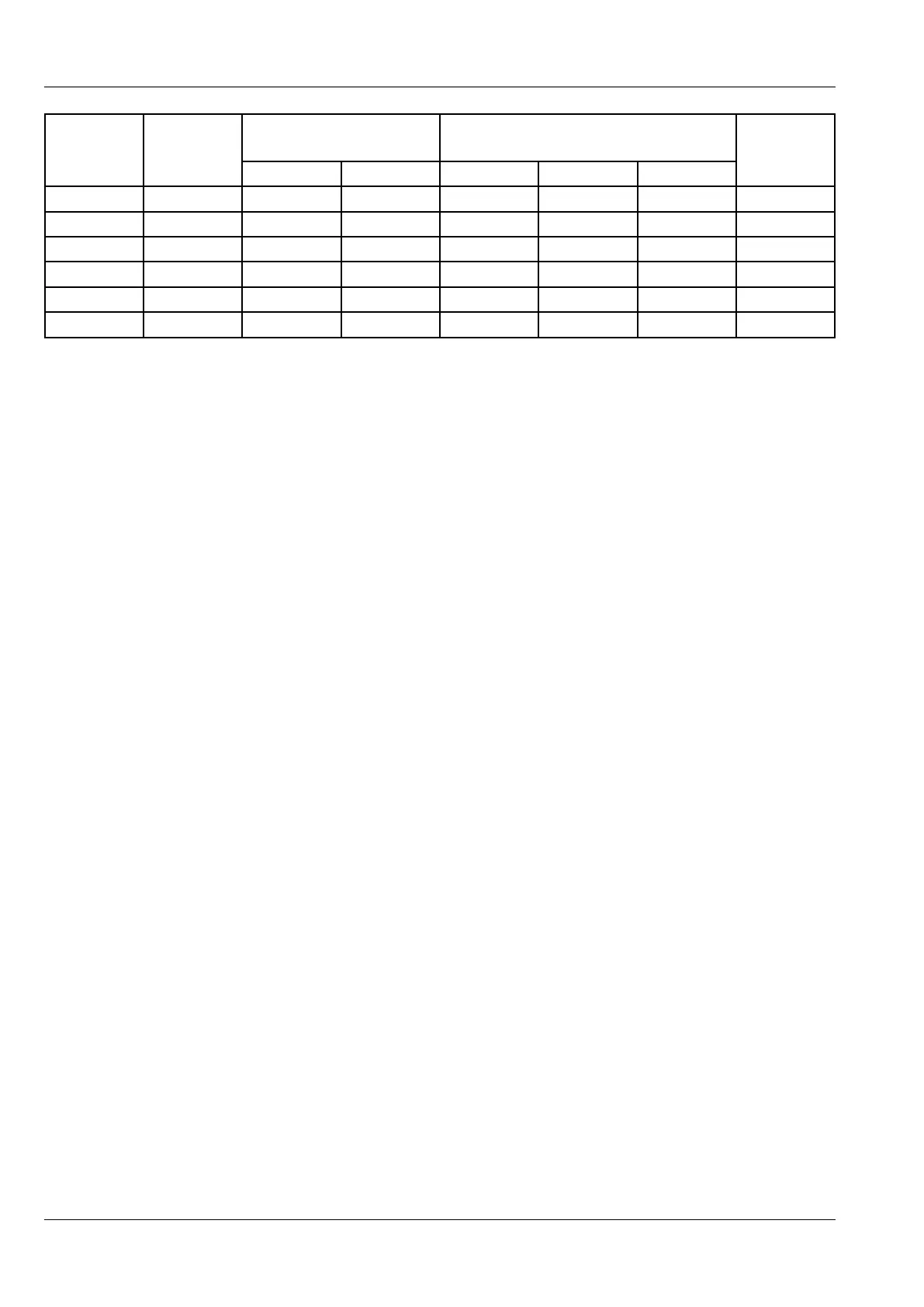

Nozzle type

Work-piece

thickness

(mm)

Pressure

(bar)

Consumption

(Nl/h)

Cutting

speed

(mm/min)

Oxygen Fuel gas Cutting O

2

Preheat O

2

Fuel gas

1. 5 - 10 2.0 0.2 1200 1180 310 660 - 550

2. 10 - 15 2.5 0.2 2100 1180 310 550 - 490

3. 15 - 30 3.0 0.25 3400 1370 360 490 - 400

4. 30 - 40 3.0 0.25 4300 1370 360 400 - 350

5. 40 - 50 3.5 0.3 6500 1860 490 350 - 320

6. 50 - 100 4.0 0.3 11000 1860 490 320 - 200

5.1.6. Pre-ignition check

Prior to the torch being ignited, it is advisable to make a dry run on the workpiece, ensuring that the

cut path matches the profile shape required.

5.2. Ignition and flame adjustment - oxy propane cutting

The following information relates solely to Oxy Propane cutting, for alternative gases such as

Acetylene, seek advice from your gas supplier. Use the cut chart data as a guide, adjust the gas flow

pressure at the regulator, after ignition further adjustment to the flame may be required.

1. Unscrew the fuel gas valve on the torch, a 1/4 turn.

2. Unscrew the oxygen preheating valve on the torch, a 1/2 turn and ignite the gas flow at the

torch tip.

3. Gradually unscrew the fuel gas valve and oxygen preheating valve on the torch, until the

required Neutral flame is achieved. See images of the carburizing, oxidizing and neutral flame

profiles.

4. Approximate distance between the cutting nozzle face and the workpiece:

Propane gas 8 - 10mm

5. A neutral flame, correct nozzle size, travel speed and torch height are required to achieve

the desired profile cut finish. The cleaning of profile parts is easy when all parameters are set

correctly.

6. Ensure the nozzle size used is suited to the material thickness, a nozzle that is too big in

size for thin material will cause the material to distort and have a poor cut quality, likewise,

a nozzle that is too small for thick material will travel too slow, cause edge damage and

possible incomplete severance of the part. Flashbacks can occur from cutting with incorrect

settings, ensure “Flashback Arrestors” are fitted, used correctly and maintained.

7. To maintain a constant cut quality, ensure settings are adjusted as required, use the supplied

nozzle cleaning kit to keep the nozzle clean and free from dross and spatter.

Loading...

Loading...