EX-TRACK

®

Operator Manual, Revision T-148

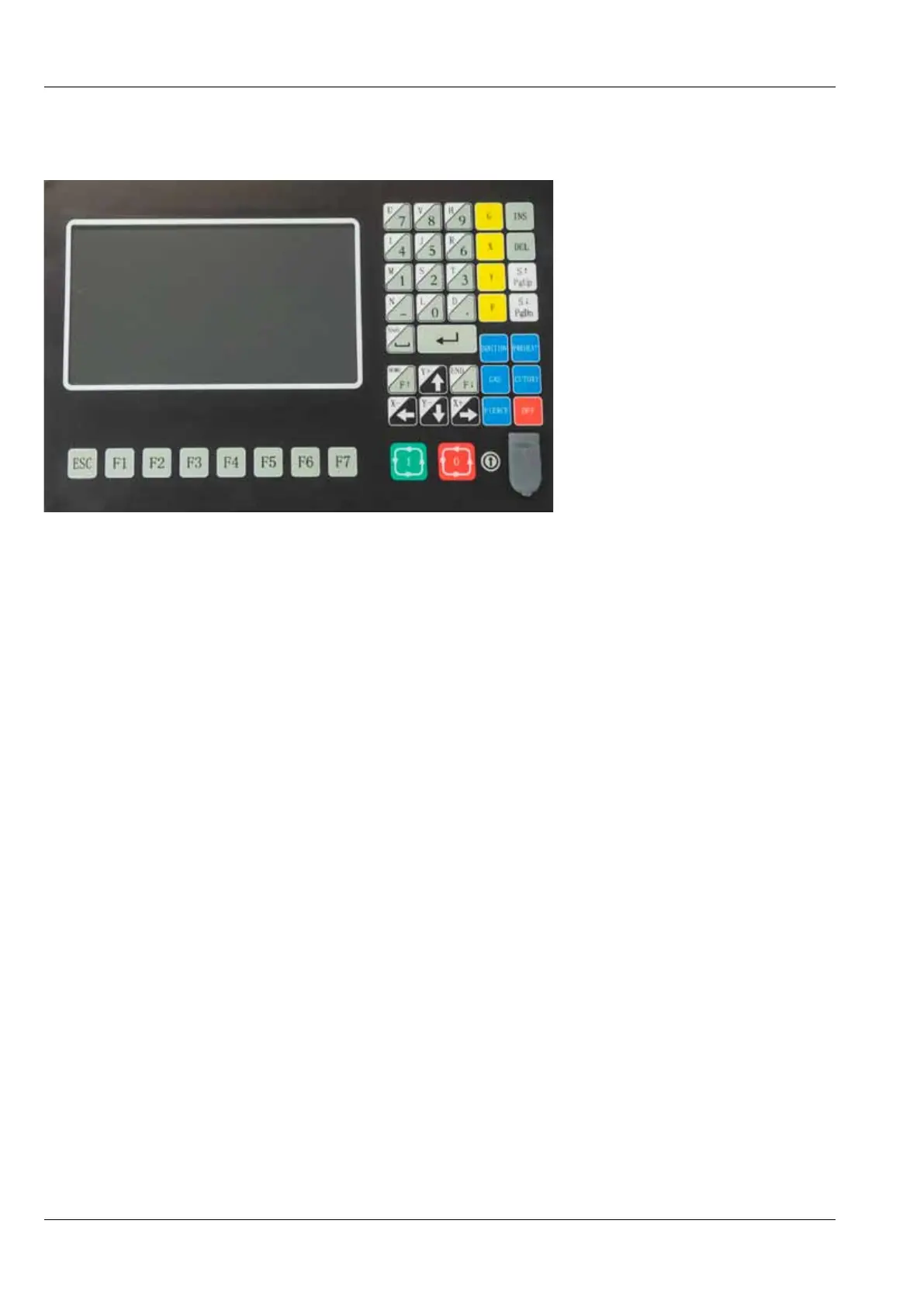

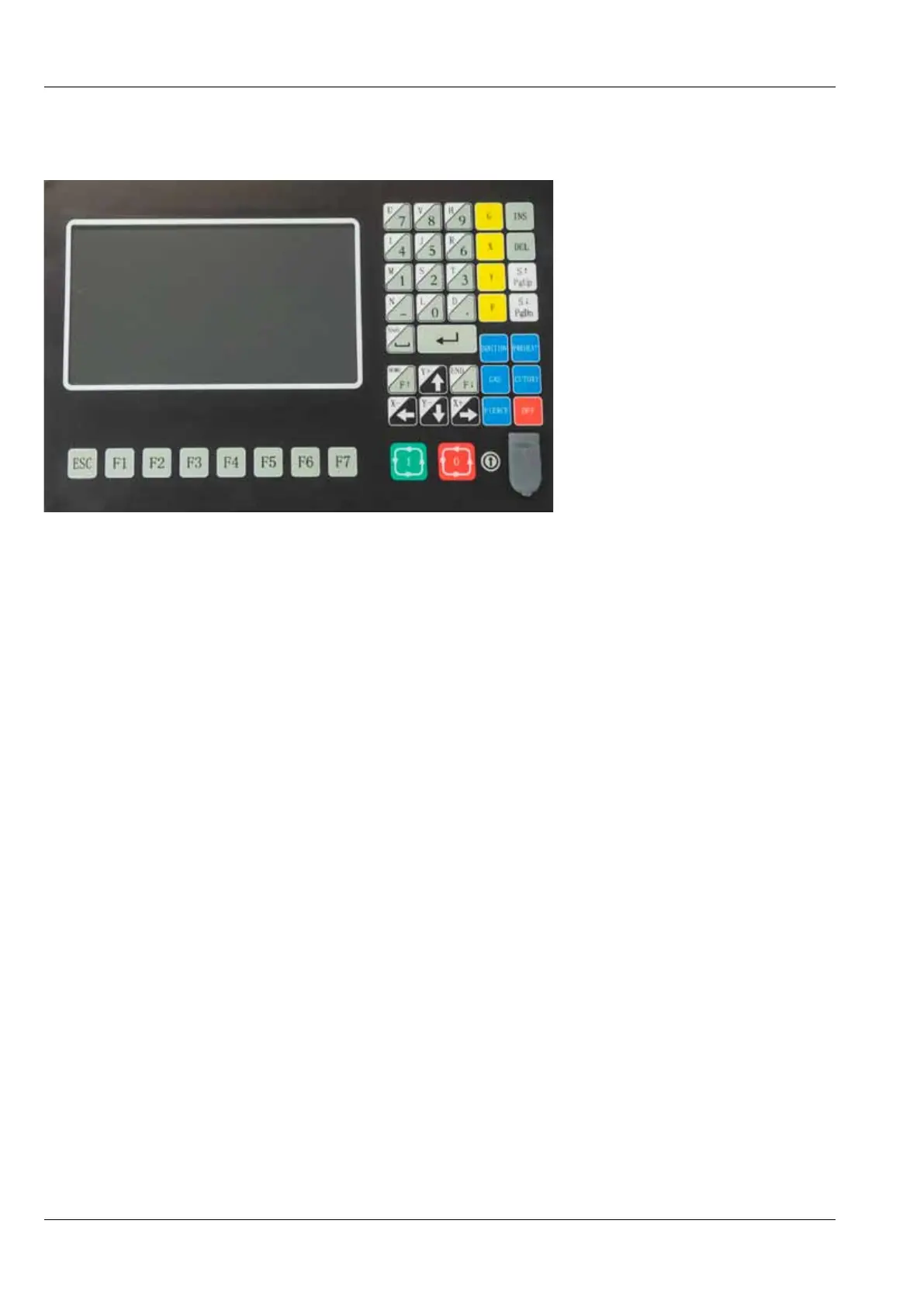

9.1. Control panel functions

9.2. CNC system functions

1. Versatile CNC cutting system, suitable for use with oxy fuel and plasma cutting processes.

2. The system is reliable and protected against electrical interference from plasma cutting and

fluctuation in the power input.

3. Automatic height control and change of direction speed control, built-in kerf compensation

and monitoring.

4. “AVC” Arc Voltage Control, maintains correct torch to work piece distance during plasma arc

cutting process.

5. No loss of program data through sudden power loss, re-start at last position.

6. Dry run/trace capability, shape check and workpiece alignment/fit up.

7. Quick program access to any line or pierce/start point in a single or nested program.

8. Suited for use in a wide variety of applications in the metalworking industry.

9. Internal library of 50 pre-programmed customizable patterns/shapes.

10. STARCAM nesting software and FASTCAM nesting software are fully compatible. Interface

conversion, in both English and Chinese language, customizable to other languages.

11. Dynamic graphic display, 1 to 8x zoom, automatically follows torch position.

12. USB port for loading software, updates and CNC programs.

NOT to be used for CHARGING PURPOSES.

1. Display

2. Input keys

3. Menu / Function keys

4. Start button

5. Stop button

6. Software update button

7. USB / Dongle port

Note:

USB port has low power

for file transfer only.

Not for telephone charging.

1

2

3

4 5 6 7

Loading...

Loading...