EX-TRACK

®

Operator Manual, Revision T-1 35

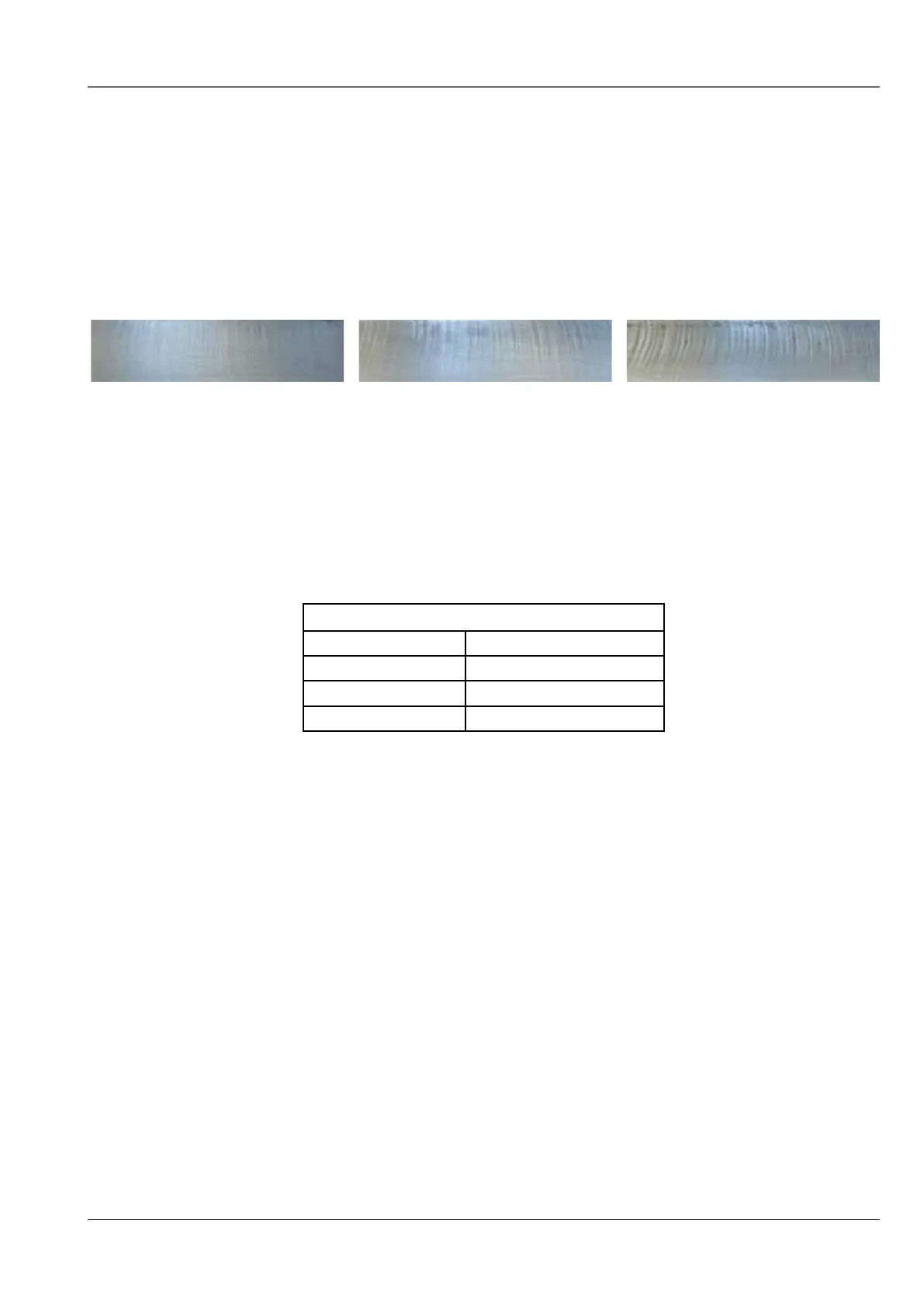

5.3. Cut quality

Acceptable cut quality is dependent upon many factors, quality that is acceptable in some instances

may not be for others. Make a test cut prior to a production run to ensure the required cut quality

has been achieved.

Use the images below as a guide to correct travel speed.

5.4. Preheat time

Preheat time for edge starts or piercing are dependent upon nozzle size, flame value, material

type/thickness and ambient temperature of the material. The chart below is intended as a guide to

preheat times, actual times may vary.

Average preheating time (in seconds min. / max.)

Work-piece thickness Propane

Up to 20 mm 8 / 34

To 50 mm 10 / 53

To 100 mm 22 / 100

Note: Incorrect piercing of thick material can result in damage to the nozzle, torch and system,

for cutting 50mm thickness or greater, use the running or flying pierce technique, this should be

performed only by experienced operators. Using a drilled hole is an alternative method for piercing

thick material, this enables an edge start to the cutting process. Frequently check the nozzle for

debris build up or damage, a blocked or damaged nozzle can cause flashbacks and poor cut quality.

5.5. Torch operation

Prior to the torch being set in motion, the operator needs to ensure that the work area is free from

flammable and combustible materials, the system can be operated without colliding with structural,

fixed or moving objects, the work area shall be cleaned, free from material off cuts and checked for

slip, trip and fall hazards.

Turning the torch off. Upon completion of the cutting process, raise the torch, turn off the cutting

oxygen supply at the torch, turn off the fuel gas supply at the torch and the turn off the oxygen cut

preheat gas supply at the torch. At the end of the shift, raise the torch and “home” the torch to where

Speed is too slow

(65%)

Speed is correct

(100%)

Speed is too fast

(135%)

Cutting direction → Cutting direction → Cutting direction →

Loading...

Loading...