Firmware Version 3/4.31.37

After establishing the number of flow meters assigned to the preset, indicate the number of components that will

be delivered through the load arm. Set the Blending Type parameter to SEQ (Sequential Blending). For multiple

meter runs, the Blending Type parameter may also be set to RAT+SEQ if some recipes will be using ratio

delivery.

Low Flow and High Flow rates are established in the Weights & Measures/Preset menu. The Low Flow Start and

Low Flow Restart volumes are also specified on this screen. These parameters define the flow profile.

Meter Setup

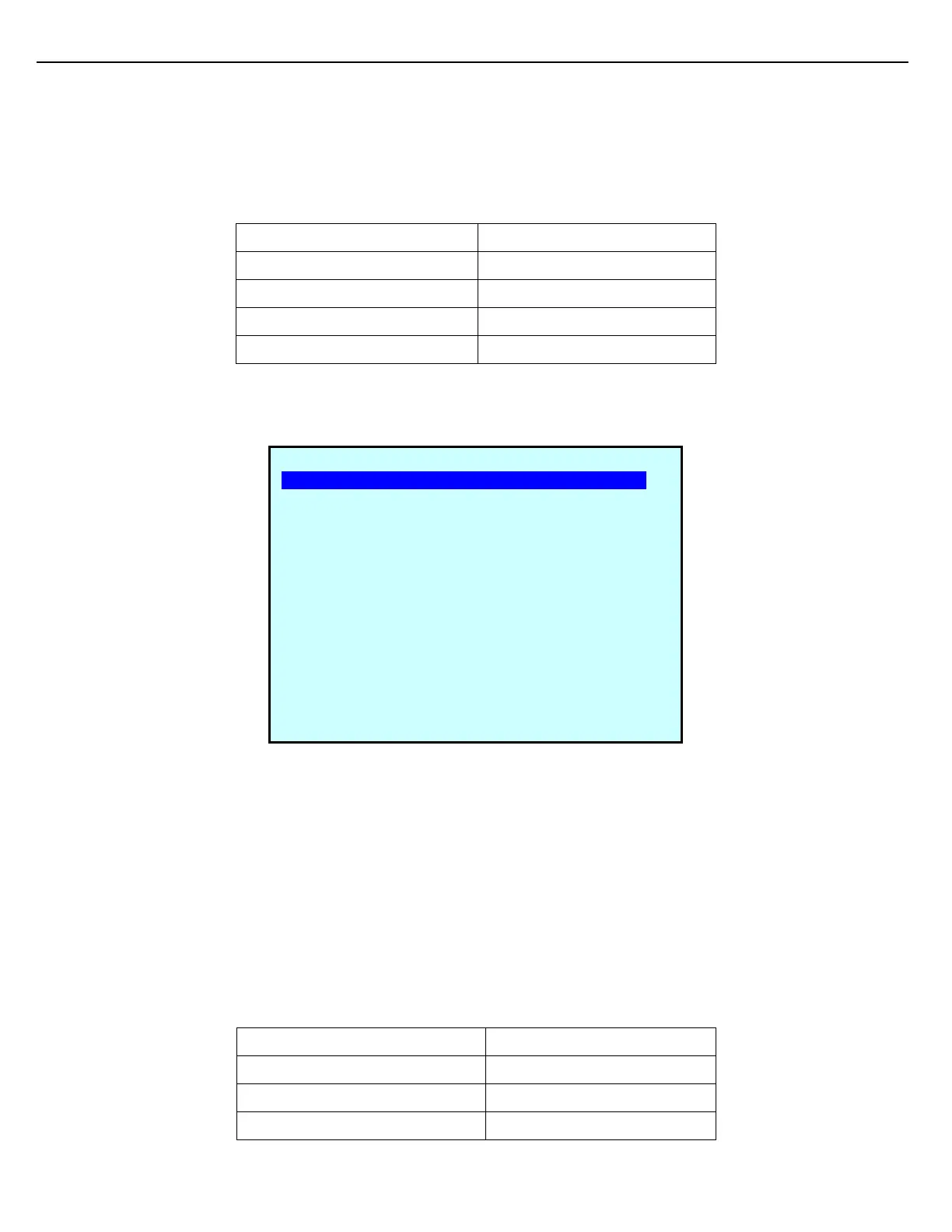

The next phase of sequential blending configuration occurs at the Meter level on the Meter setup screen.

Enter the Flow Control Module number that will receive the flow meter input. Valid choices are 0-31. The number

of a FCM is determined by the communication address of the module. The address is determined by the setting

of the DIP switch (S1) that is located on the FCM. The switch position indicates a binary zero when it is in the Off

position; a binary one is represented by a switch in the On position.

The A channel of the flow meter signal will always be on Port 4 of the selected Flow Control Module. If a channel

B signal is used for pulse security that input will always be connected to Port 5. If channel B is not used, Port 5

can be assigned to some other I/O function. Port 2 will automatically be assigned to be the control valve's NO

Solenoid signal. Port 3 will be used for the control valve's NC Solenoid signal.

The Dead Band rates for the flow stages are configured on this screen. No Valve adjustments will be attempted

when the flow rate is within the dead band. Whenever flow drifts outside of the dead band, the valve will make

adjustments to bring the flow rate back within the dead band.

If multiple meters are assigned to the preset, repeat this process for the other meters.

PRE #1 MTR #1 SETUP

Flow Control Module#: 0

Side-Stream on Mtr# 0

Side-Strm on Any Mtr# DISABLD

Meter Address: 0

Meter Type: VOL PUL

Max Quad Errors: 10

Reset Quad Errors: 10000

Low Flow Alarm Rate: 10

Low Flow Alarm Time: 10.000

Excess Flw Alrm Rate: 800

Minimum Flow Rate: 50

Maximum Flow Rate: 650

Low Flow DB Rate: 40

High Flow DB Rate: 40

Next Prev Exit Enter

Loading...

Loading...