Firmware Version 3/4.31.37

Component Setup

Component parameters related to Sequential Blending are found on the Component Setup screen, shown here.

Scroll down the screen to view additional parameter fields.

Configure component #1. Assign the component to Meter #1. Typically, one flow meter is used for sequential

blenders. If more than one meter is assigned to the blender, assign the component to the appropriate Meter #.

Assign the output that will signal the Block Valve to open. If applicable, assign an output signal to force the block

valve to close. An optional Block Valve Status signal can be configured. Assign an input point to receive the

feedback signal. The block valve input and output signals can be assigned to any available port. For FCM I,

ensure that the Opto module is appropriate for the type of voltage that will be used.

Block valve open and closing alarm times can be configured. If the Block Valve Status signal is not received in

the specified time, block valve alarm will be raised and the load will be stopped.

The Pump Start port assignment for the component is configured on this screen. Additionally, there is a Pump Kill

output that can be assigned to provide a signal to remove power from the pump. An option also exists to

configure a Pump Status signal to provide positive verification that a pump is running. The pump related input

and output signals can be assigned to any Flow Control Module.

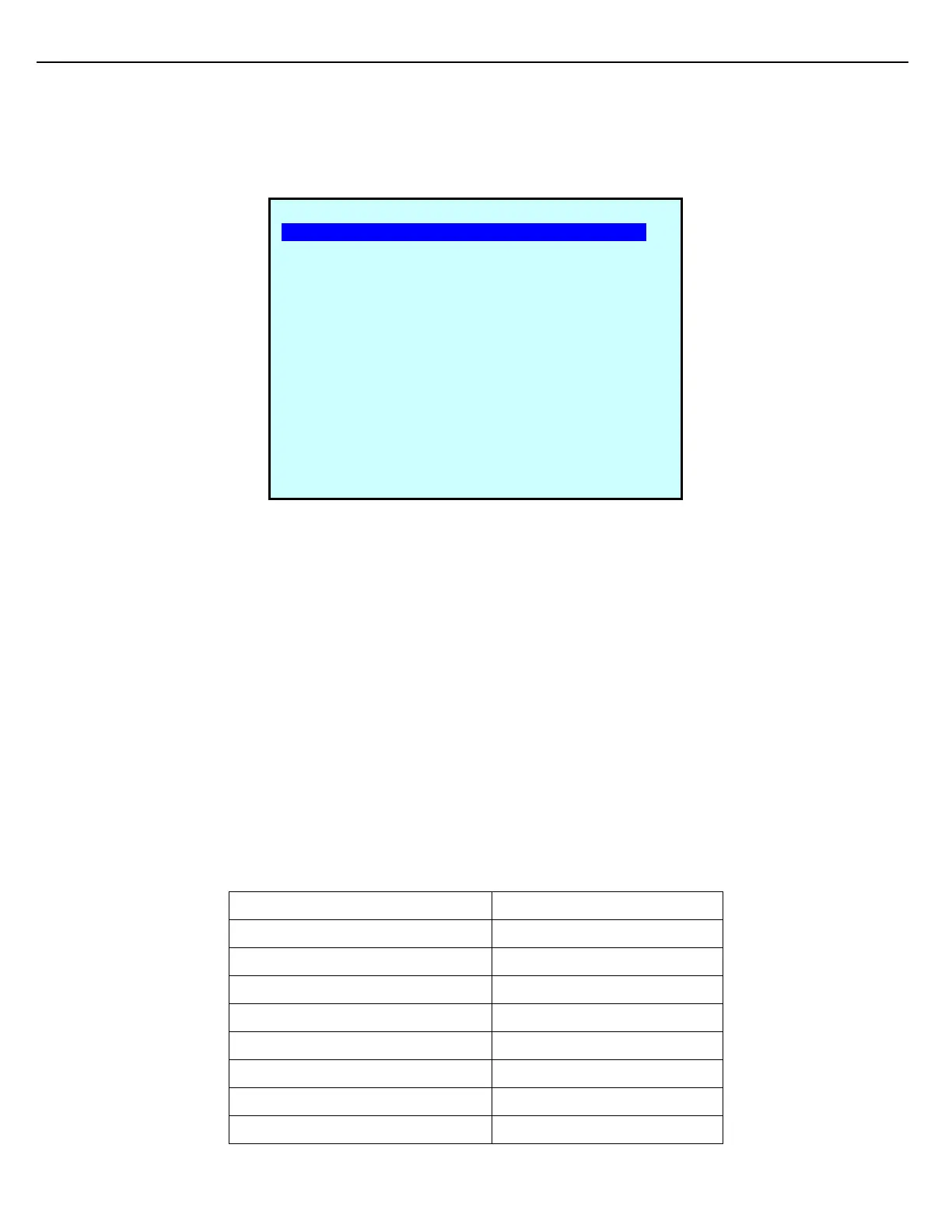

The 1st Stage Trip and the 2nd Stage Trip parameters are defined on the W&M Setup Screen. Enter the volume

and rate that defines 1st Stage Trip and 2nd Stage Trips.

If more than one component is assigned to the preset, repeat this procedure for the other components.

PRE #1 CMP #1 (Base 001 ) SETUP

Meter#: 1

High Flow Rate: 600

1st Stage Trip Volume: 70

1st Stage Flow Rate: 225

2nd Stage Trip Volume: 20

2nd Stage Flow Rate: 150

Final Trip Vol: 1.15

Final Trip Max Time: 5.000

Final Trip Vol Lock: DISABLD

Unauth Flow Alrm Vol: 10

W&M Recipe Percentage: %0.00

BlkValve Open Rate: 0

BlkValve Open Delay: 0

B.V. Open Alrm Time: 10

Next Prev Exit Enter

Loading...

Loading...