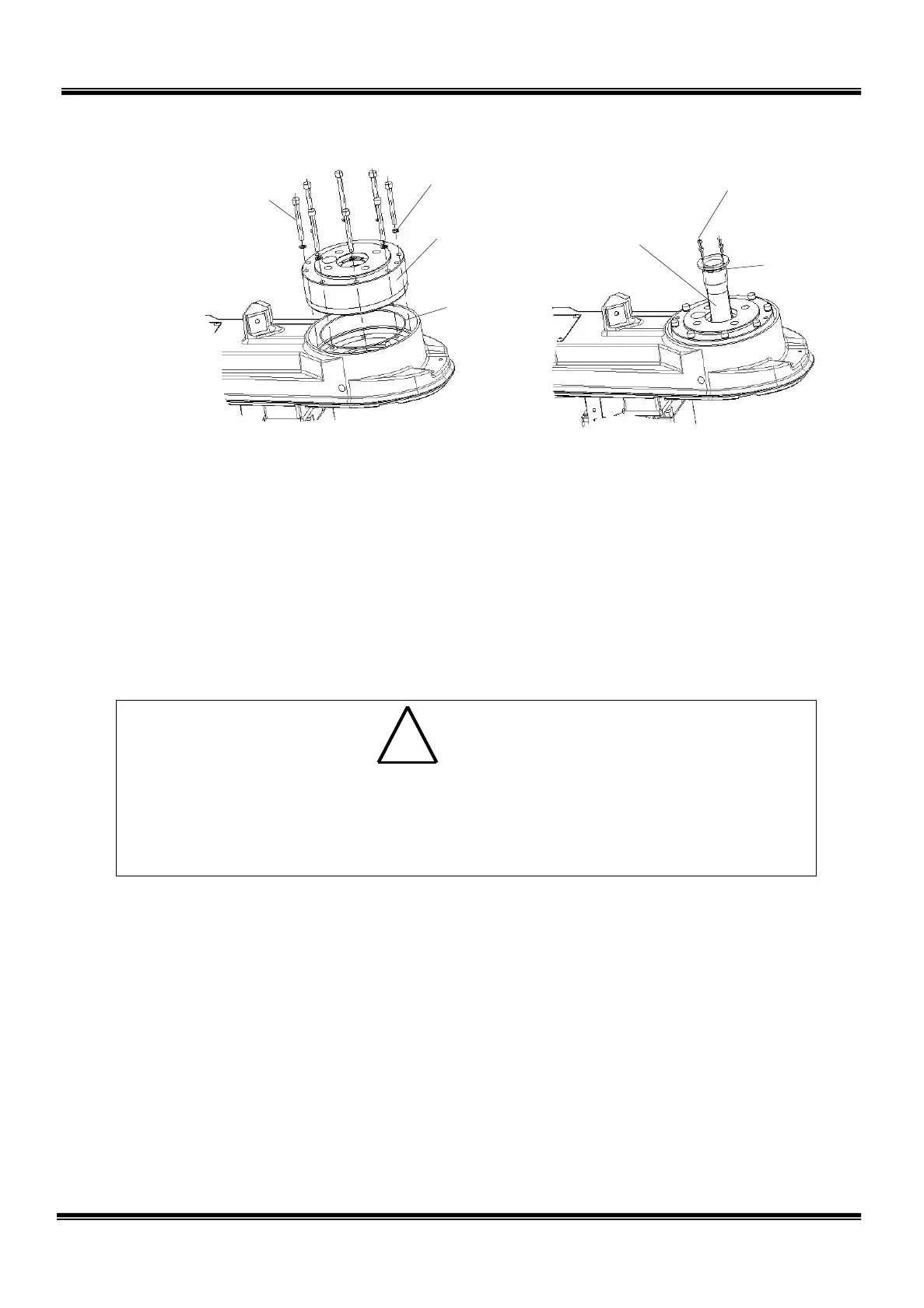

M6×55

Recommended clamping

torque: 17 N·

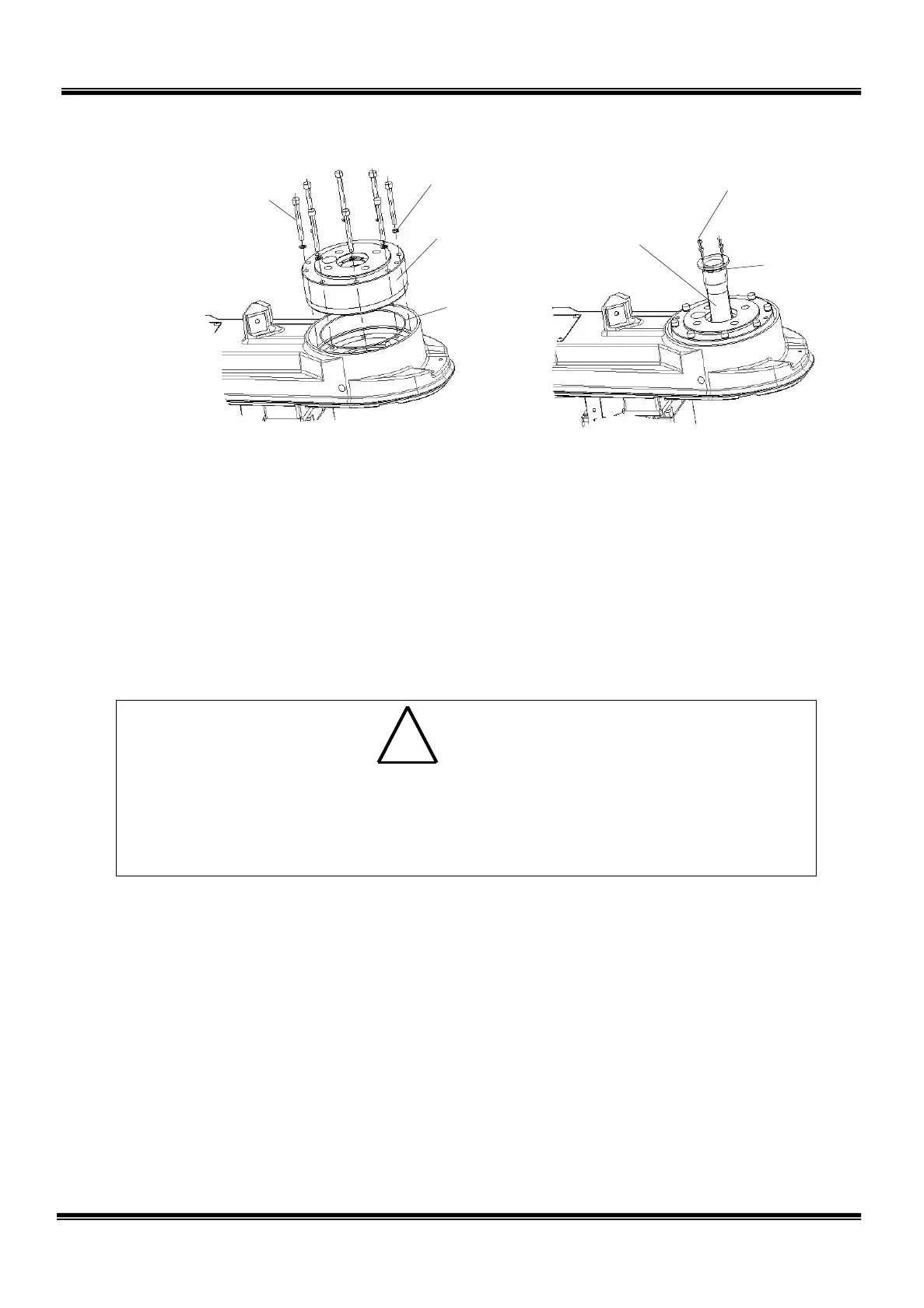

3) Set the two (2) “O” rings attached to the reduction gear in the “O” ring grooves

machined on the arm 1.

4) Mount the arm 2 with the four (4) bolts (M10 × 65). When this happens, the

clamping torque of each bolt should be 54 N·m. DO NOT tighten the bolts with

the clamping torque exceeding 54 N·m. Be sure to apply the liquid gasket to

the threaded area of each bolt.

5) Mount the new center gear on the axis 2 reduction gear.

• Be sure to observe the clamping torque of the bolts (M10 × 65) securing the

axis 2 reduction gear with the arm 1. If these bolts are tightened with

clamping force exceeding 54 N·m, the axis 2 starting torque will increase.

• Be sure to apply the liquid gasket to the threaded area of each bolt (M10 × 65).

STE 85306

– 75 –

Loading...

Loading...