BATTERY CHARGER USER’S MANUAL PART- 2: THEORY OF OPERATION

MCEnPC23-REV.2.4 Page 85

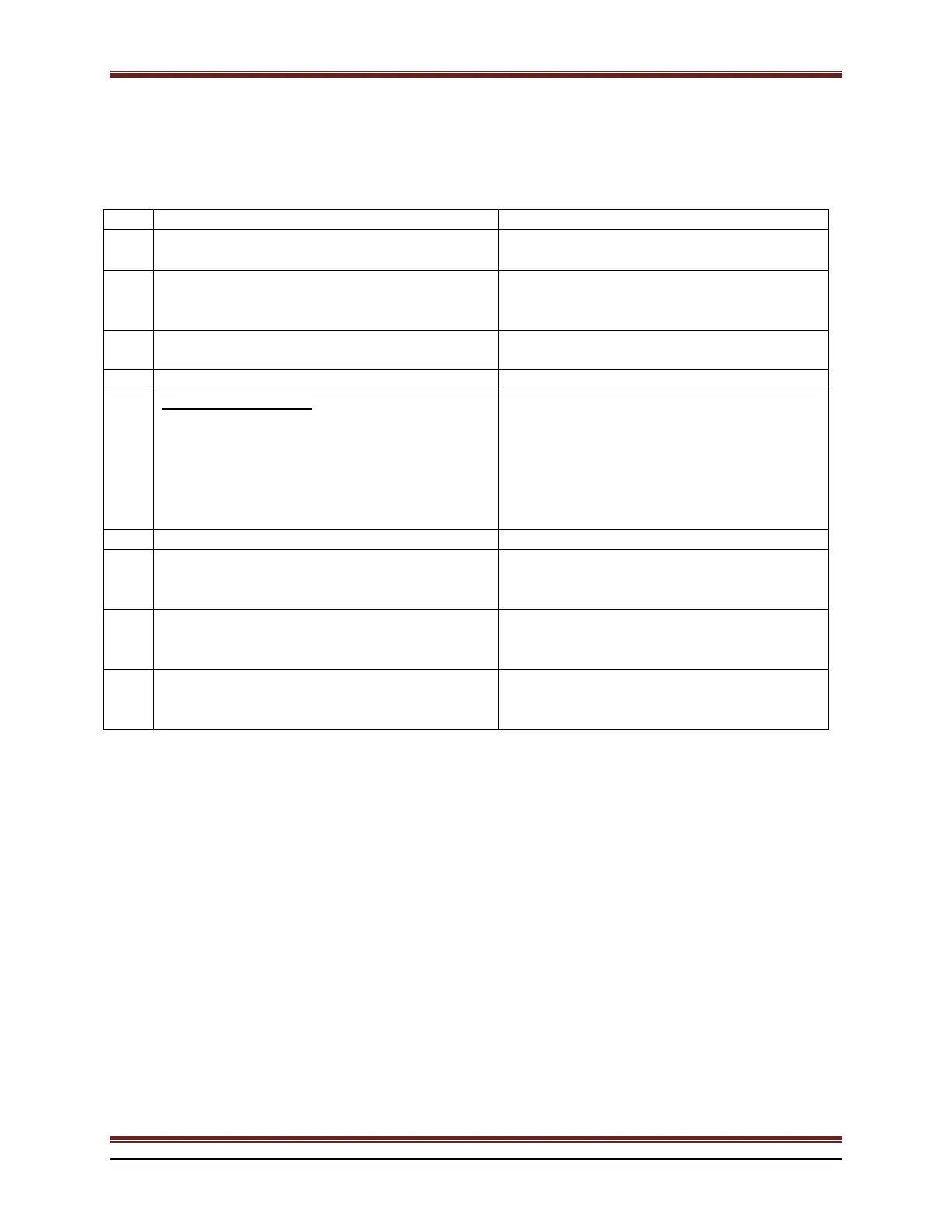

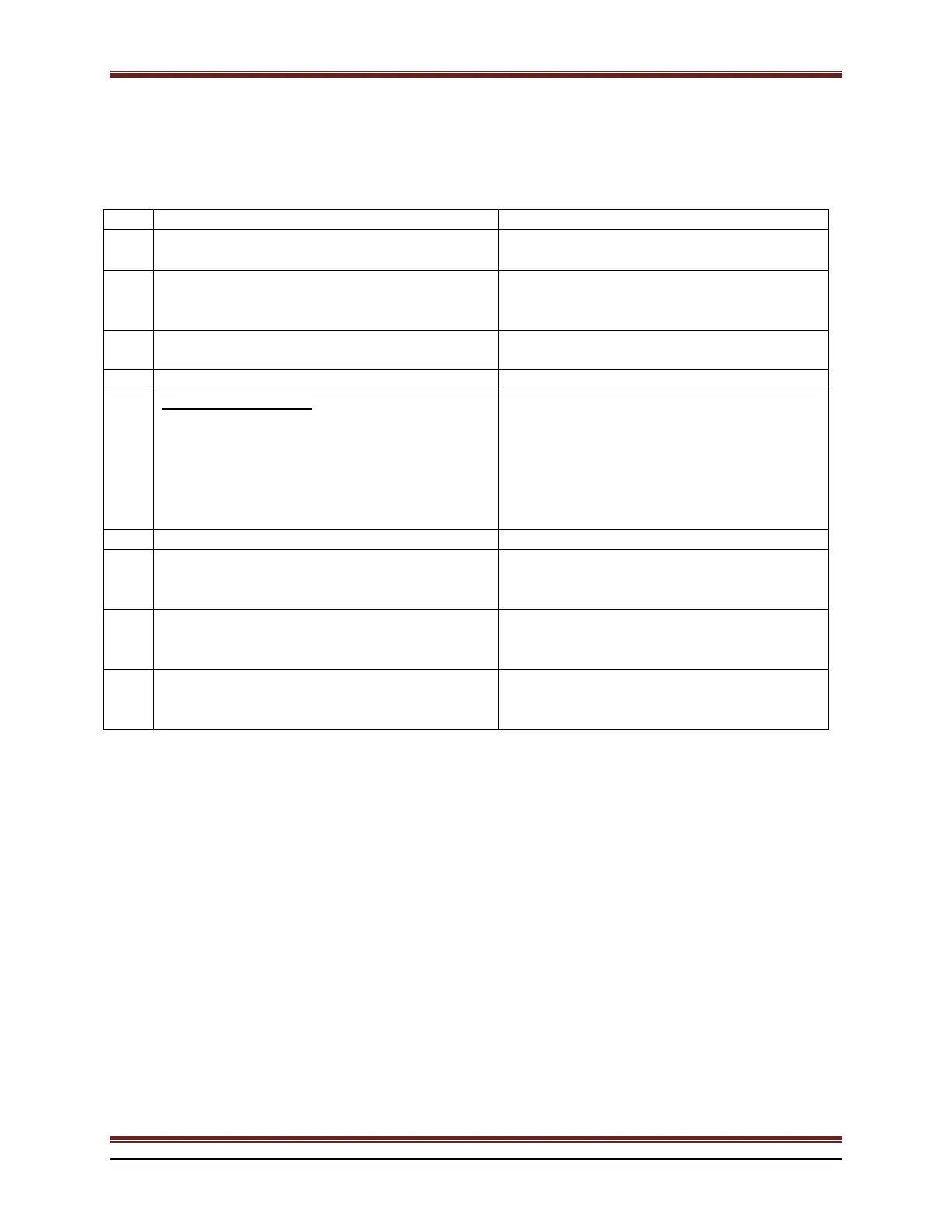

11. REGULAR PREVENTIVE MAINTENANCE

Regular maintenance is required to ensure reliable operation of your system.

Action Frequency

B Measure and record voltage across each battery

cell and across the entire battery

monthly

B Verify and record the level of electrolyte in

each battery cell. If necessary top off with

distilled water.

monthly

B Verify and record the specific gravity of each

battery cell

monthly

C Verify the operation of all indicators monthly

B, C VERY CAREFULLY (especially if you are

dealing with the conductive substances)

remove the accumulated dust around the

ventilation openings, charger interior, surfaces

of circuit boards & electrical

connectors/terminals.

As needed, depending on the environmental

conditions of the site, but minimum once a

year

B, C Visually verify the condition of all components yearly

B, C Verify all bolted connections. If necessary, use

a torque wrench to retighten to manufacturers

specifications

yearly

B Clean and grease all battery connections As needed, depending on the environmental

conditions of the site, but minimum once a

year

B Wash the battery cells using distilled water

only

As needed, depending on the environmental

conditions of the site, but minimum once a

year

B = battery C = charger

For systems supplied with lead acid batteries, a partial discharge of the battery is recommended on an annual basis,

to verify the battery and charger performances. For systems supplied with nickel-cadmium batteries a complete

discharge and decommissioning charge is recommended on a bi-annual basis.

Loading...

Loading...