Auxiliary equipment

HAMM line spreader

226

BA RD40_RD45 en 00

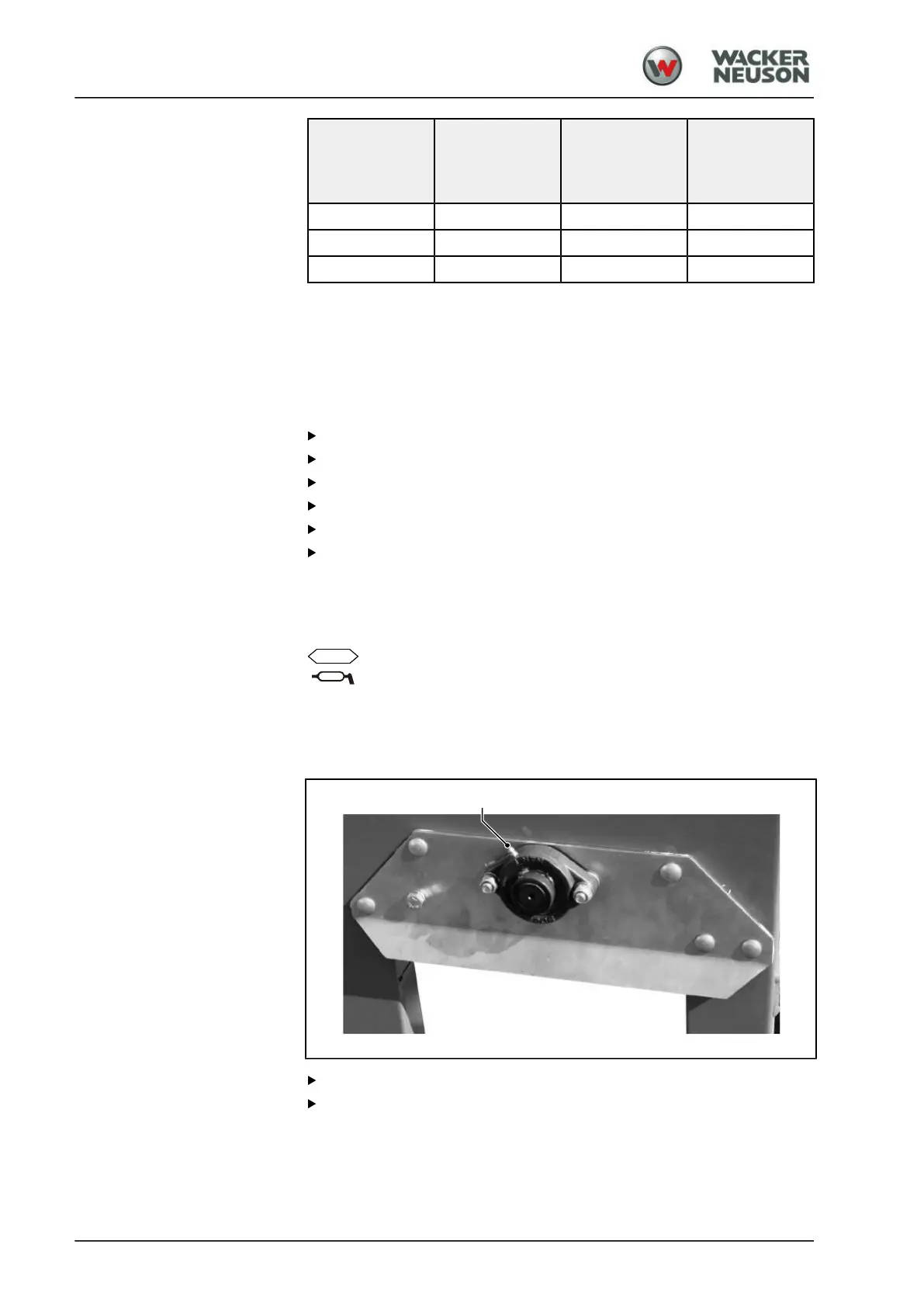

Quantity of

chips required

kg/m²

Weight of

chips on the

sheet of paper

g

Volume of

chips on the

sheet of paper

ml (US gal.)

Part of the

amount in the

metering box

1.5 94 60 3/5

2.0 125 80 4/5

2.5 156 100 5/5

6.07.04 Maintenance

For all maintenance work on the chip spreader, you must observe

the information listed in the chapter "Important information about

maintenance work", see page 119. Replace wear parts according to the

descriptions given in the manufacturer's operating manual.

Check operating and safety notes on the chip spreader.

Replace damaged and/or non-readable warning signs.

Ensure that hinges and links move easily and lubricate lightly.

Check that hydraulic and lighting connections are tight.

Check lighting.

Check screw connections which are heavily loaded and make sure

they have a tight seat.

Maintenance overview

Every 250 operating hours

Grease bearings

Grease bearings

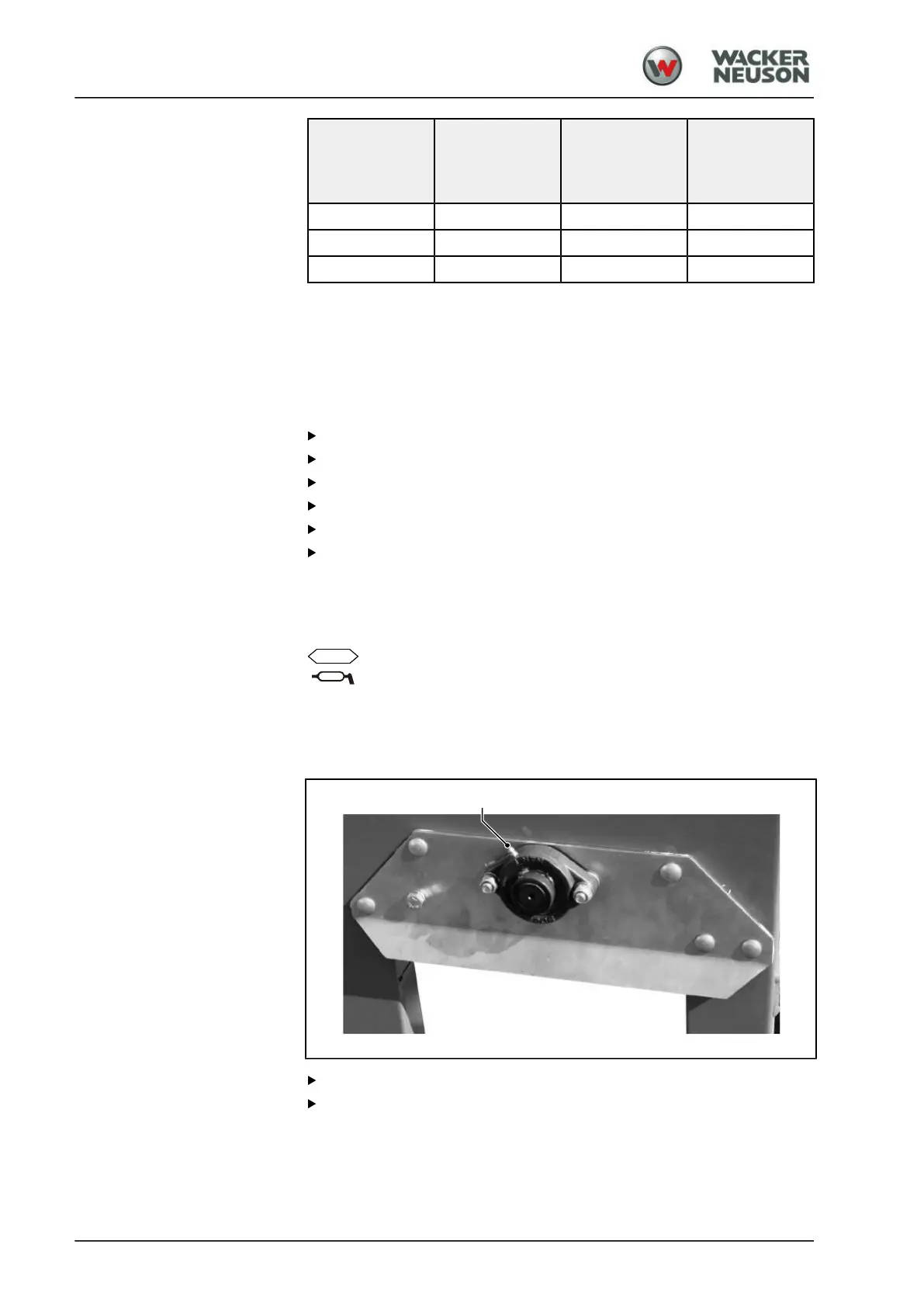

" Lubricant only admissible if containing this marking ("Technical data",

page 162 sqq.).

Switch off diesel engine and remove ignition key.

Grease lubricating nipple [1].

Loading...

Loading...