PROCEDURE

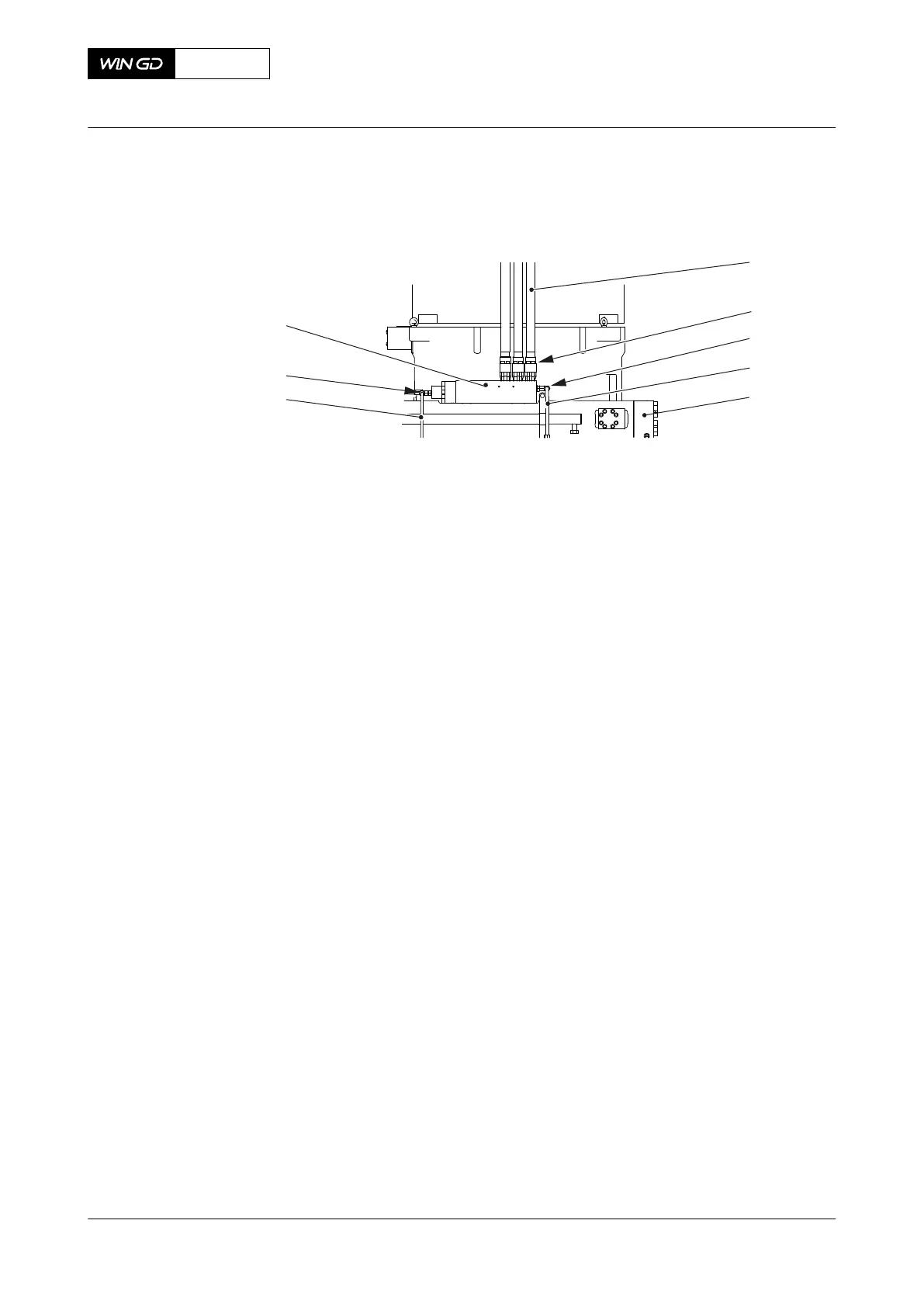

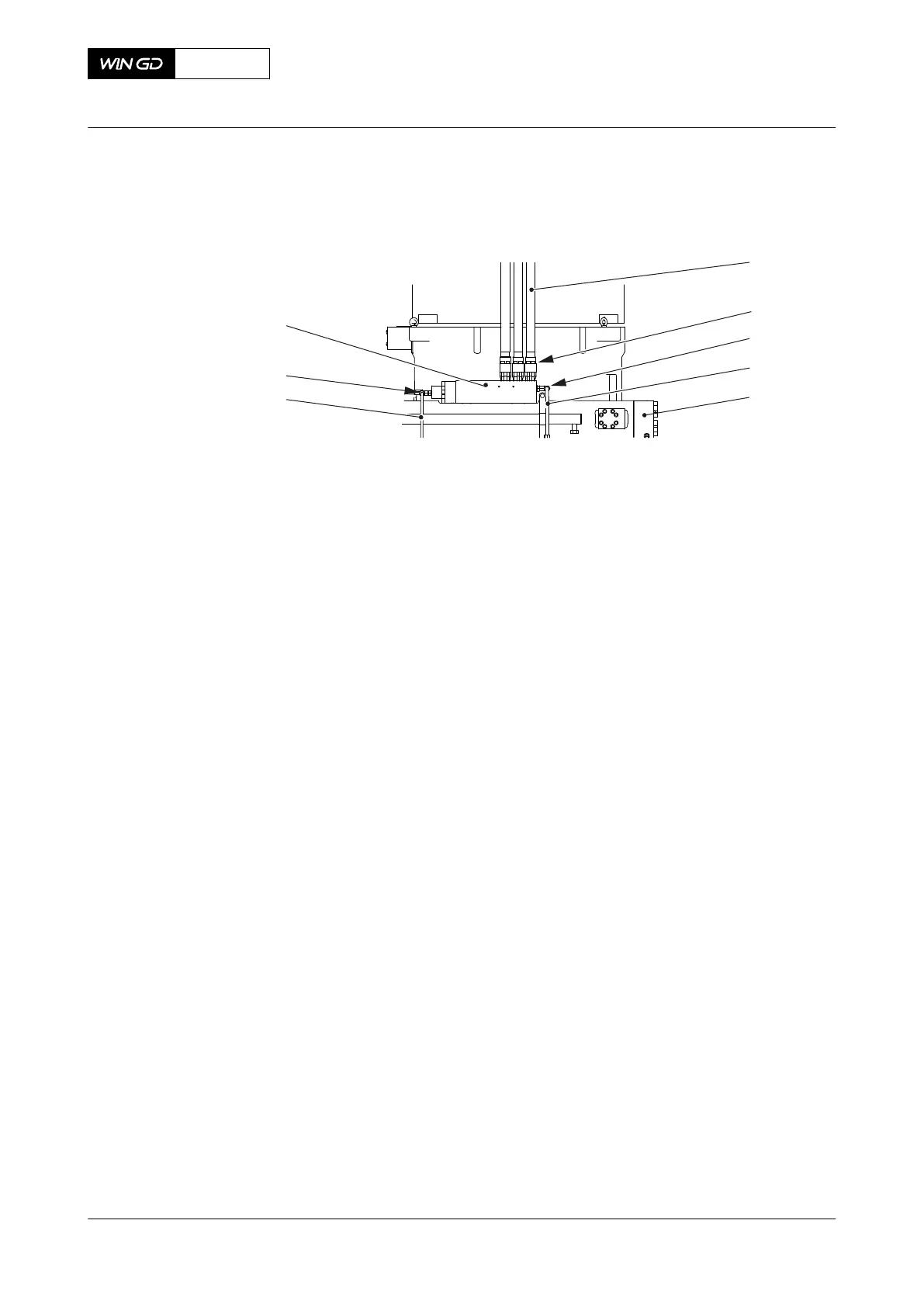

Fig 10-3 Leakage on FLV and pipes (example)

Legend

001 HP fuel pipe to injection valve 005 Fuel rail

002 Screw 006 Fuel leakage pipe

003 Screw-in union 007 Screw-in union

004 Fuel leakage pipe 008 Flow limiting valve (FLV)

1 Do a check of the level switch LS3446A for free flow. If necessary, clean the bore of the

pipe of the level switch.

2 Carefully do a check of the temperature of the fuel leakage pipe (004, Figure 10-3) of each

flow limiting valve (FLV) (008) to find the leakage pipe that has a fuel flow.

NOTE: There is a fuel flow in the leakage pipe that has a higher temperature than the

other leakage pipes.

NOTE: As an alternative you can carefully open and close the screw-in union (003) of

each FLV a maximum of two turns to find the leakage pipe that has a fuel flow.

3 If there is a leakage pipe (004) that has a fuel flow, do as follows:

3.1 Make sure that the screws (002) are tightened correctly, refer to the Maintenance

Manual 8733-1.

3.2 On the fuel leakage pipe (004), carefully loosen the screw-in union (003) a

maximum of two turns.

3.3 Do a check for fuel flow.

3.4 If fuel continues to flow from the screw-in union (003), do as follows (an HP fuel

pipe (001) is defective):

3.4.1 Stop the engine.

3.4.2 Remove each of the HP fuel pipes (001) until you find the defective HP fuel

pipe (refer to the Maintenance Manual 8733-1).

3.4.3 Do a check for damage on the sealing face of the defective HP fuel pipe

(001). If you find damage, grind the sealing face (refer to the Maintenance

Manual 8733-1).

3.4.4 If the HP fuel pipe is defective, cut out the injection of the related cylinder

and replace the defective HP fuel pipe, refer to the Maintenance Manual.

3.4.5 Tighten the screw-in union (003).

3.4.6 Start the engine.

3.5 If no fuel flows from the screw-in union (003), tighten the screw-in union (003).

X72-B

AA00-0000-00AAA-311C-A

Operation Manual Examine the FLV or fuel pipes for fuel leakage

Winterthur Gas & Diesel Ltd.

- 419 - Issue 003 2021-12

Loading...

Loading...