PROCEDURE

1 Clean the seating surface of the bearing shell (004, Figure 8-36).

2 Put bearing oil on the surface of the bearing shell (004) as follows:

2.1 If you start the engine immediately after completion of this procedure, use only

system oil.

2.2 If the engine has stopped for some days, use a mixture of steam engine cylinder

oil (high viscosity oil) and bearing oil.

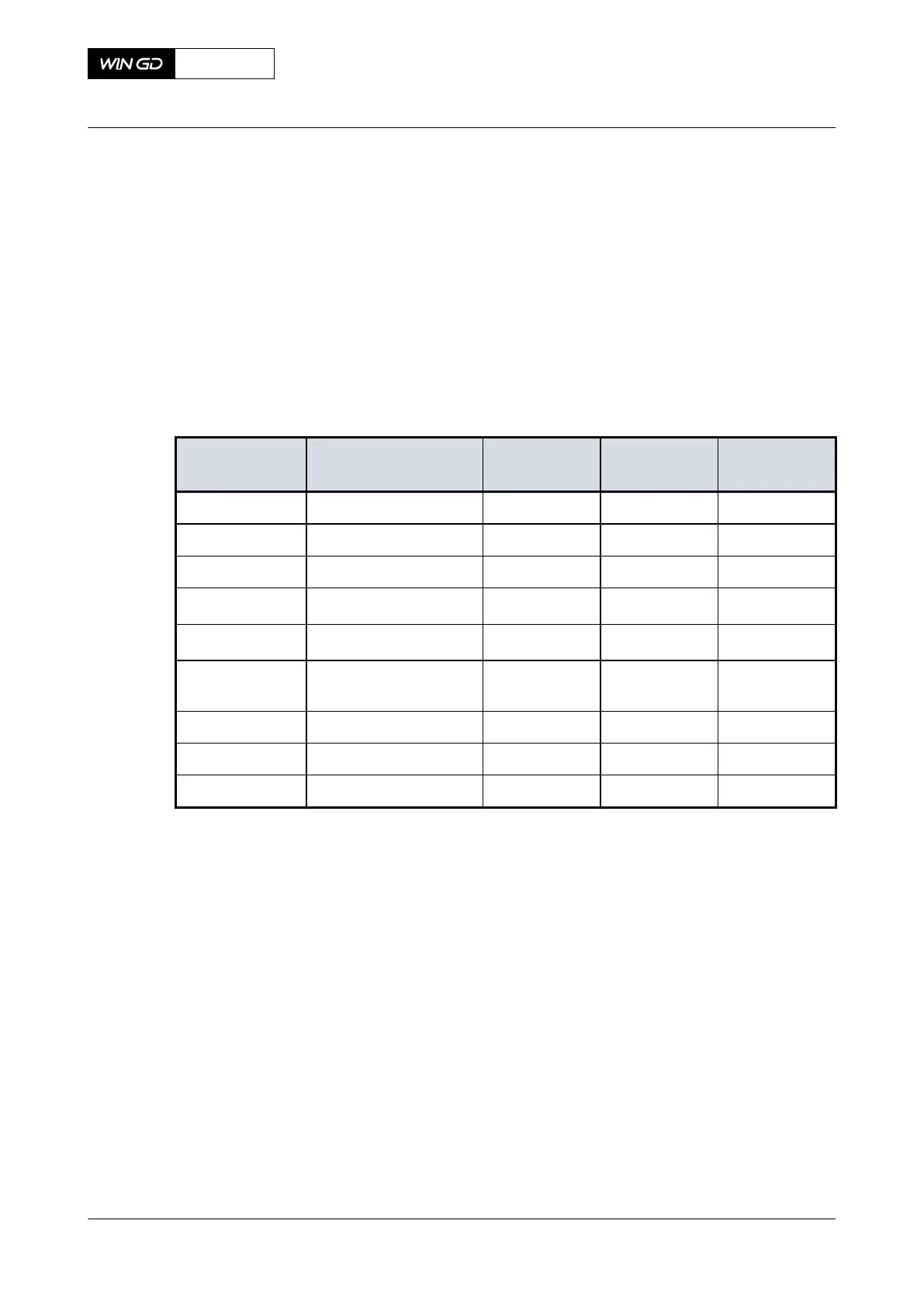

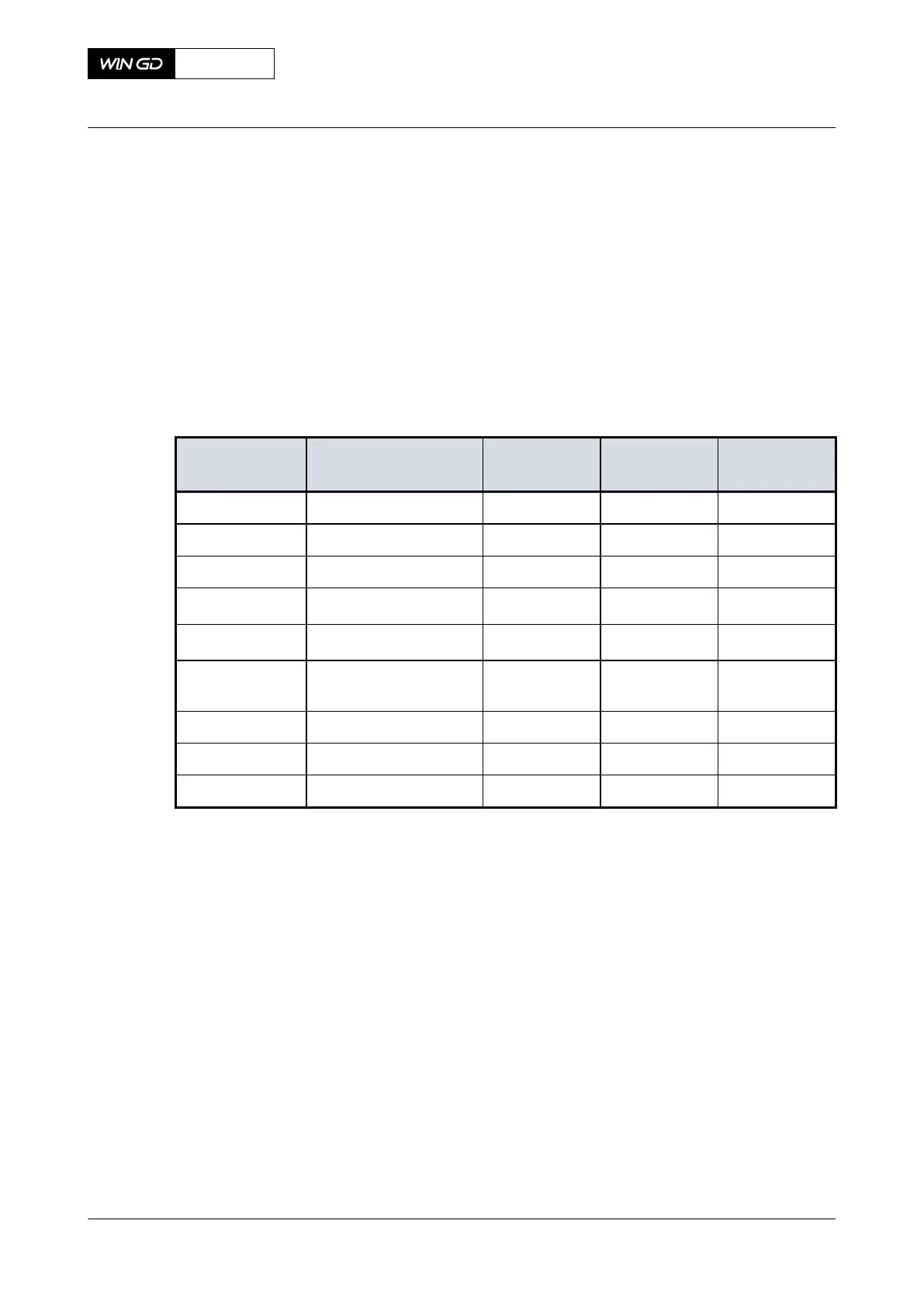

NOTE: The ratio is two thirds ISO VG 1000/1500 to one third bearing oil. A list

of suppliers for high viscosity oils is given in Table 8-5 - ISO VG

1000/1500 suppliers below.

Tab 8-5 ISO VG 1000/1500 suppliers

Supplier Type Viscosity at

40°C [mm

2

/

s

]

Viscosity at

100°C [mm

2

/

s

]

Weight at 15°C

[g/ml]

BP Energol DC 1000 980 49.0 0.913

BP Energol DC 1000 920 40.0 0.913

Chevron Cylinder oil 1000 1000 43.1 0.937

Exxon/Esso Cylesso 1000 950 44.0

Exxon/Esso Cylesso TK1000 925 46.7

Mobil Extra Hecla super cylin-

der oil

680 39.0 0.905

Shell Fiona oil 1500 1500 37.0 0.958

Shell Valvata oil 1000 1000 45.4 0.924

Texaco 650T mineral oil 985 44.0 0.919

3 Clean the seating surface of the connecting rod and make sure that there is no damage.

4 Make sure that the surface of crosshead pin is in a satisfactory condition.

5 Install the brackets (008) on the bearing shell (004). Make sure that the lugs face in.

6 Attach the chain (010) to the brackets (008).

7 Attach the sling (006) to the gallery.

8 Make sure that the deviation pipe (001) is attached to the column.

9 Attach the spur-geared chain block (005) to the sling (006) and to the chain (010).

10 Operate the chain block (005) to lift the bearing shell (004).

11 Attach the lever chain hoist (007) to the chain (010).

12 Operate the chain block (005) and the lever chain hoist (007) to move th bearing shell

(004) through the column door.

13 Operate the lever chain hoist (007) and the chain block (005) to lower the bearing shell

(004) into position in the connecting rod (003).

14 Attach the bearing shell (004) to the connecting rod with the two screws (009).

15 Remove the lever chain hoist (007) and the chain block (005).

16 Remove the brackets (008).

17 Attach the lever chain hoist (002) to the lifting tool on the connecting rod (003).

X72DF

AA00-3303-02AAA-720A-A

Maintenance Manual Connecting rod - install the top end bearing

Winterthur Gas & Diesel Ltd.

- 421 - Issue 002 2020-10

Loading...

Loading...