PROCEDURE

1 Disassemble the cylinder lubricating pump as follows:

1.1 Remove the solenoid valve (011).

1.2 Put the cylinder lubricating pump with the air vent screw (010) point down into a

vice with soft jaws.

1.3 Remove the set screw (016, Figure 12-4).

1.4 Remove the screws (001).

NOTE: The base (002) is under a small spring tension.

1.5 Remove the base (002), the pin (005), the plungers (014) and the spring (006)

together. This helps to keep the plungers (014) in position with the base (002).

1.6 Remove the main piston (012) with the help of the four holes in the center of the

main piston (012).

NOTE: Do not use the holes for the plungers (014) for this step.

1.7 Push out the slide rod (008) with an applicable tool.

1.8 Remove the O-rings (003, 004) and the piston joint ring (009).

1.9 Remove the pressure transmitter (015).

1.10 Remove the screw plugs and the check valves (013) from all pump outlets with a

hexagon key.

1.11 If there was air leakage during operation - remove the air vent screw (010).

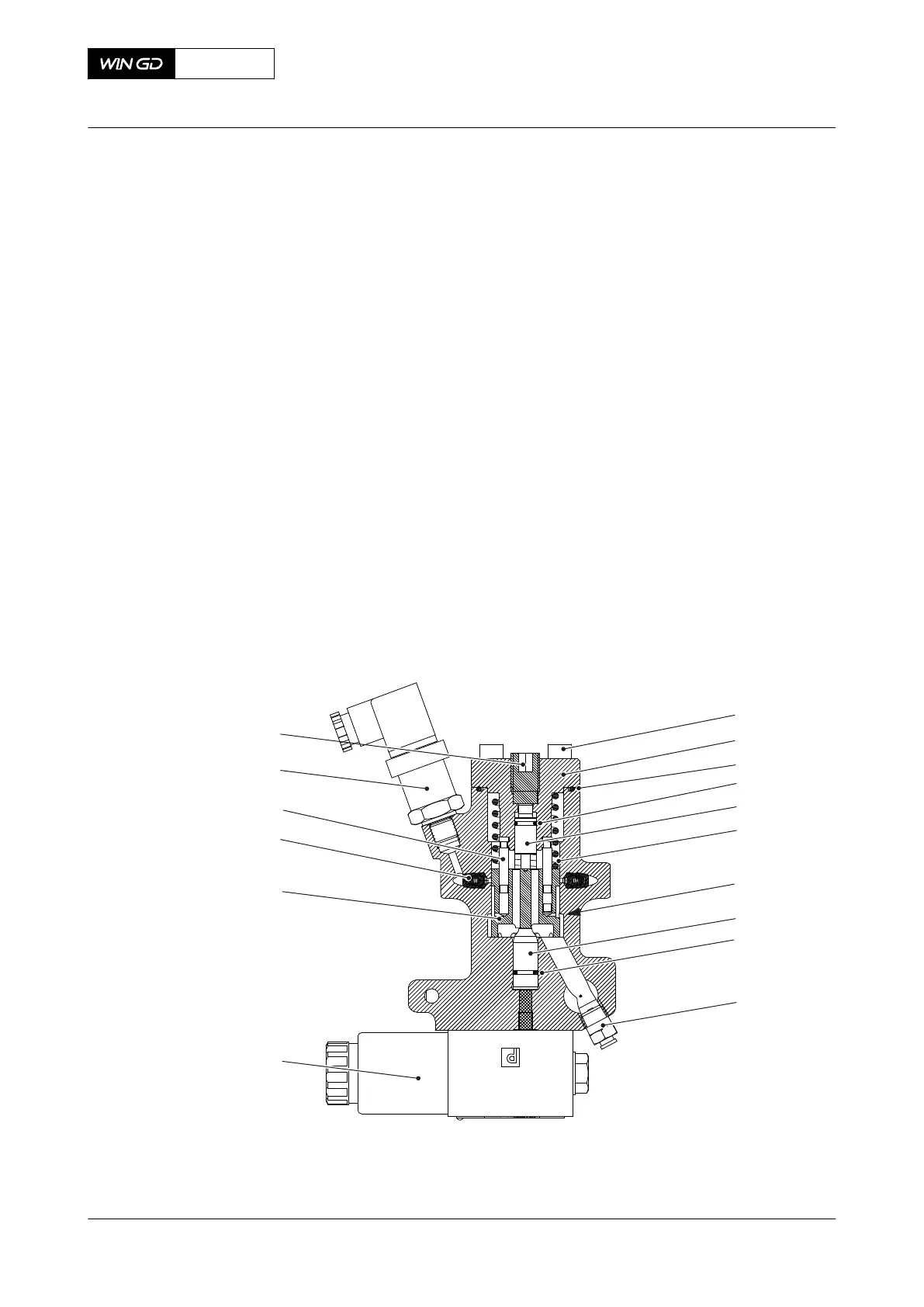

Fig 12-4 Cylinder lubricating pump (MK-E)

001

002

003

004

005

006

008

009

007

010

015

013

012

011

014

016

X72DF

AA00-7206-00AAA-200A-A

Maintenance Manual Cylinder lubricating pump (MK-E) - do a service

Winterthur Gas & Diesel Ltd.

- 683 - Issue 002 2020-10

Loading...

Loading...