120

6.2.4 Operation steps

Estimate the inertia through the driver panel

1. Parameter setting

Inertia identification

and internal

instruction

auto-tuning max

speed

Inertia identification

initial inertia ratio

The recommended parameters of P2-17 are 500 rpm or more. Low instruction speed will lead to

inaccurate identification of inertia ratio.

2. Execute the inertia identification

Before inertia identification, please confirm the direction of servo rotation by using F1-00 jog motion

function. Initial direction of servo operation is determined by INC or DEC at the beginning of inertia

identification.

If the servo jitter is under the adaptive default parameters, please switch to the adaptive large inertia

mode (P2-03.3=1) to ensure the basic smooth operation of the servo and then identify the inertia!

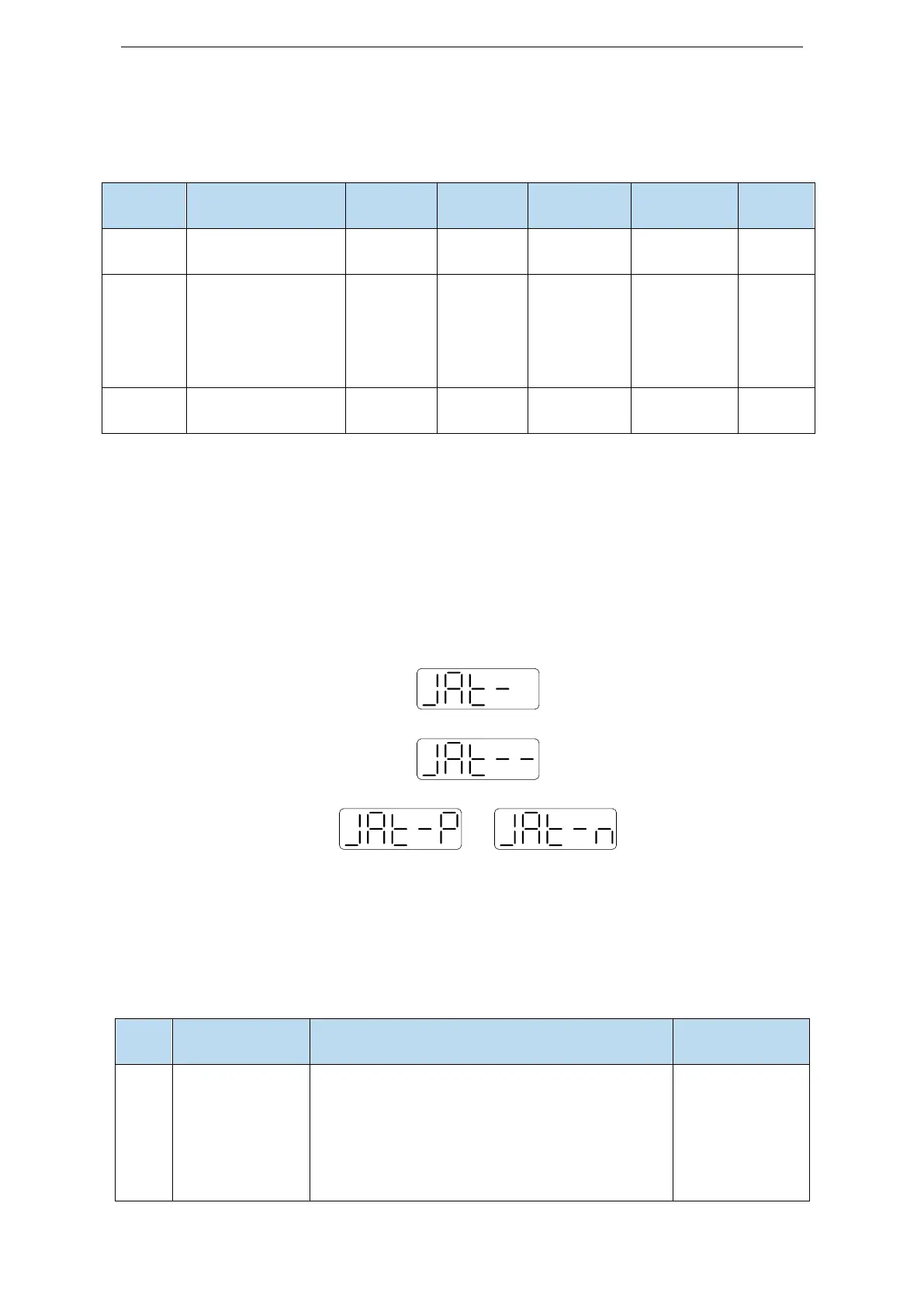

Servo entering parameter F0-07 in BB state:

Press ENTER, servo is enabled:

Press INC or DEC to run forward or reverse (select one of them):

or

At this point, start action, under the condition of P-05 = 0 (initial positive direction), if press INC, then

turn forward and then reverse; if press DEC, turn reverse and then forward. If the inertia identification

is successful, the load inertia ratio is prompted and written to P0-07 automatically after several forward

and reverse operations. If the inertia identification error occurs, the error code will be displayed. Press

STA/ESC key to exit the panel inertia identification operation.

Alarm for inertia identification of panel

① Initial inertia is too small; in adaptive mode,

switch to large inertia mode P2-03.3=1 or the initial

inertia of inertia identification P2-18 set to 2 times

of the present value.

② The maximum speed is too high (P2-17), but it is

recommended not to be less than 500 rpm. Low

Initial inertia too

small; Maximum

speed too large;

Torque limit too

small

Loading...

Loading...