50

5 Operation of servo system

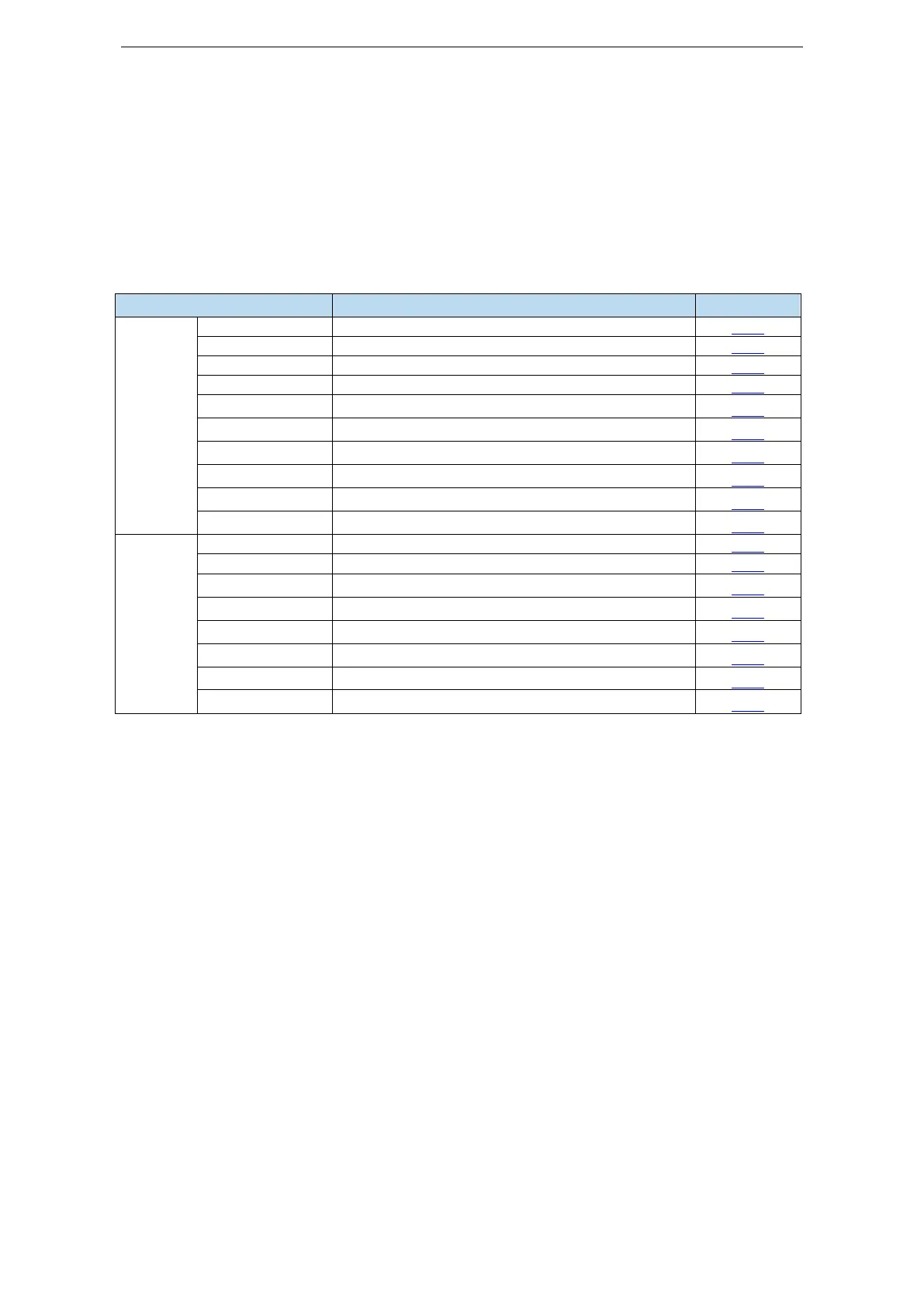

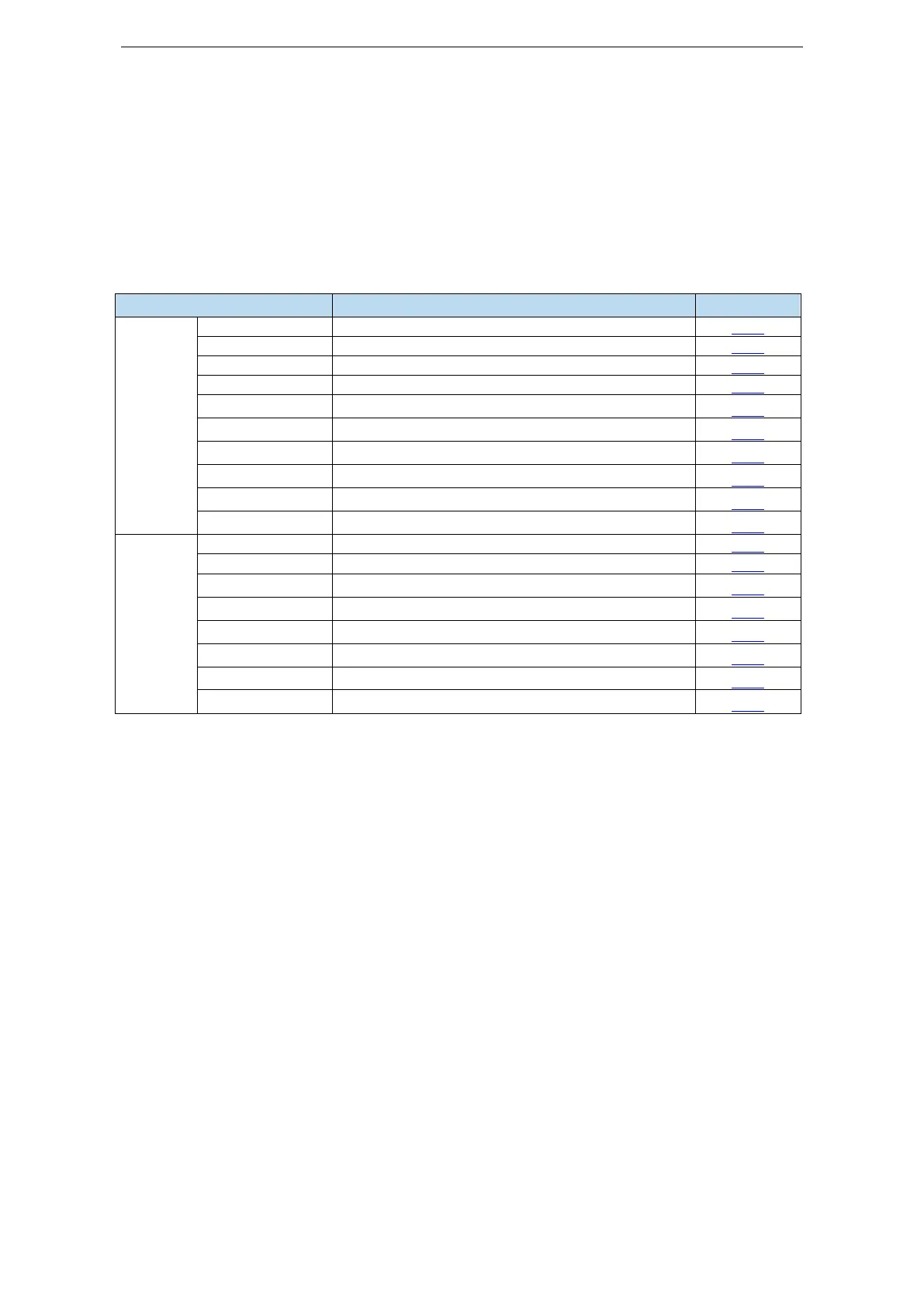

5.1 Control mode selection and switching

5.1.1 Control mode selection

Servo can combine two control modes and switch between them. By switching freely between mode 1

and mode 2 through the / C-SEL signal, more complex control requirements can be satisfied.

Torque control (internal setting)

Torque control (external analog value)

Speed control (internal setting)

Speed control (external analog value)

Position control (internal position instruction)

Position control (external pulse instruction)

Speed control (pulse frequency instruction)

Torque control (internal setting)

Speed control (internal setting)

Position control (internal position instruction)

Position control (external pulse instruction)

Speed control (pulse frequency instruction)

Position control is to input the pulse train command into the servo unit and move it to the target

position. The position instruction can be given by the combination of external pulse input, the total

number of internal position instructions and speed limit. The position is controlled by the number of

input pulses, and the speed is controlled by the frequency of input pulses. It is mainly used in the

occasions requiring positioning control, such as manipulator, grinder, engraving machine, CNC

machine, etc.

Speed control is to control the speed of machinery by speed command. The servo driver can

control the mechanical speed quickly and accurately by the speed command given by digital, analog

voltage or communication.

Torque control is to control the output torque of motor by torque command. Torque command can

be given by digital, analog voltage or communication. The current of servo motor is linear with torque,

so the control of current can realize the control of torque. The torque control mode is mainly used in the

devices with strict requirements on the stress of materials, such as some tension control occasions such

as winding and unwinding devices. The torque setting value should ensure that the stress of materials is

not affected by the change of winding radius.

Loading...

Loading...