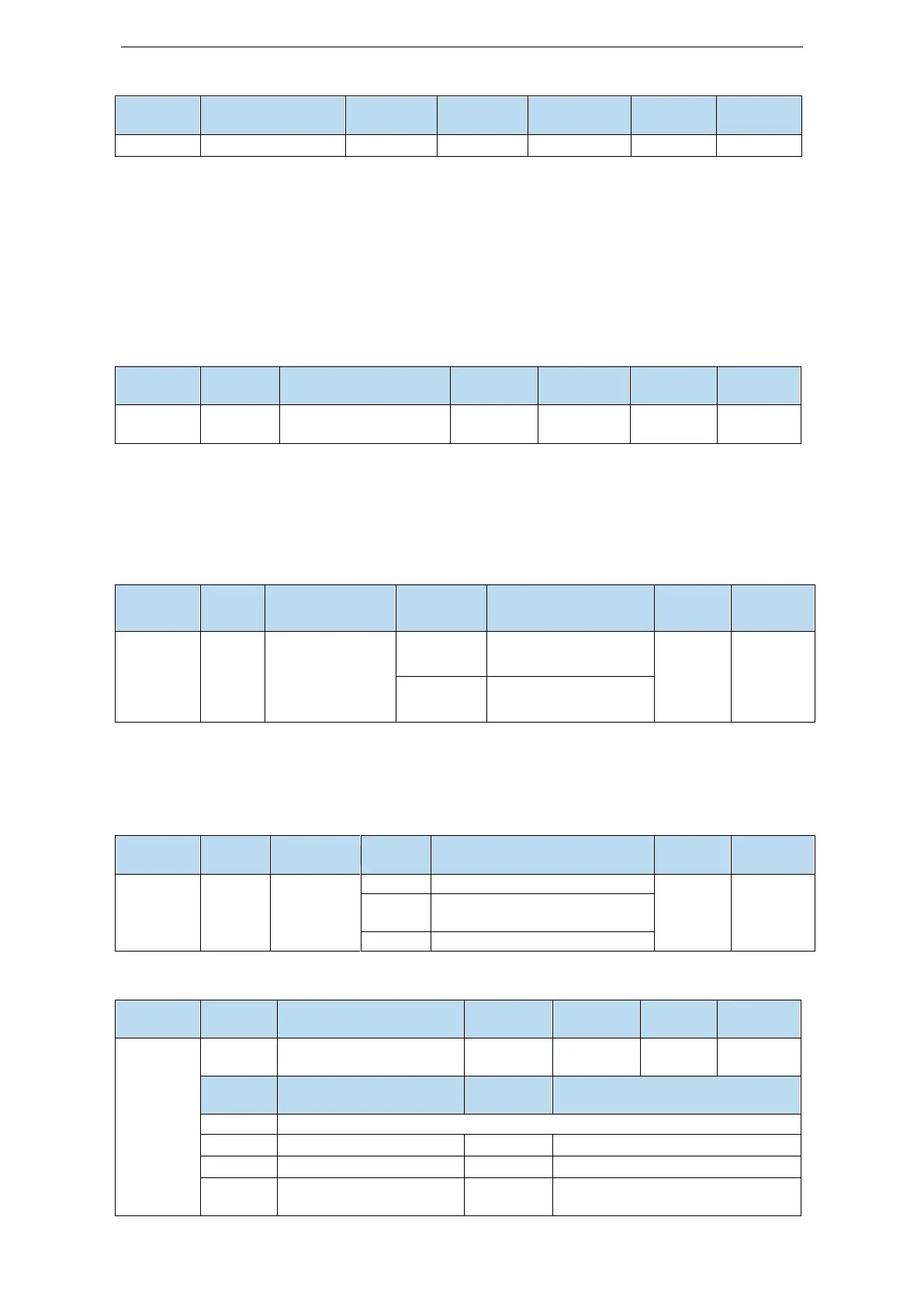

112

Related parameter

P3-18 is the speed configured for closed-loop inching operation, which only takes effect in two inching

modes, and the rest normal control modes are invalid.

(5) Run the servo system and confirm whether the full closed-loop system operates normally.

Send instructions through PLC and other upper devices to observe the operation of the servo unit.

Slowly increase from low speed to target speed and gradually confirm.

5.9.3 Full closed-loop control parameter

5.9.3.1 Full closed-loop function switch

Full closed loop

control mode switch

When the parameter is set to 0, the full closed-loop function is closed; when the parameter is set to

1, the full closed-loop function is opened, and the external encoder position signal is used for control.

Only when P9-00.0 full closed-loop function is opened, other related functions of P9-00 and P9-01

can work, otherwise, even the setting will be invalid. The opening of the full closed-loop function

requires the servo to be powered on again.

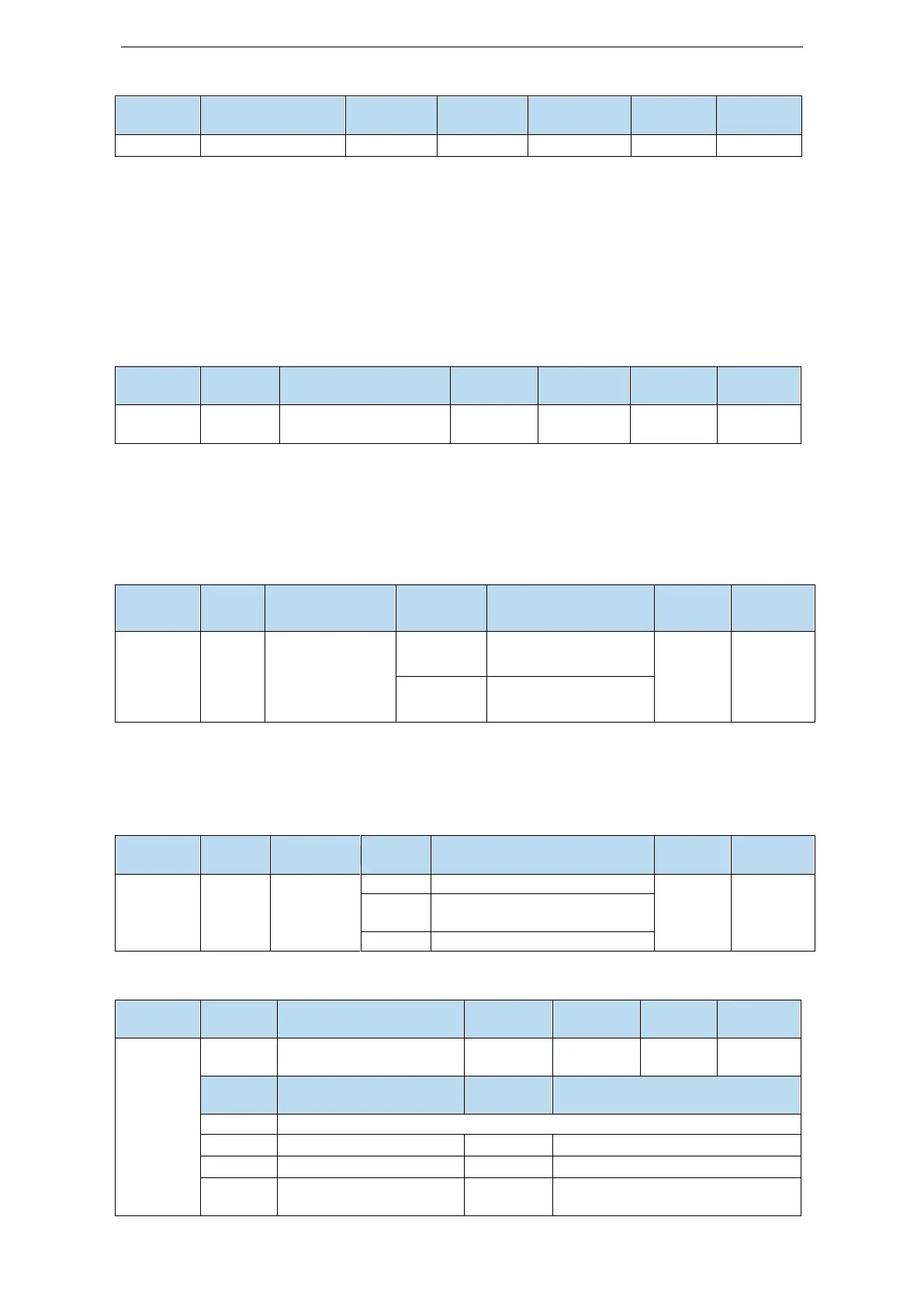

5.9.3.2 Counting direction and type selection of grating ruler

Counting

direction of

grating ruler

use the grating ruler

counting value directly

Grating ruler counting

value reversed

P9-00 shall cooperate with motor rotation direction parameter setting (P0-05) to decide whether to

change.

When the direction setting is wrong, when P9-02 is not set to 0, the alarm E-236 (alarm of

excessive deviation between motor and load position) will be output during operation, at this time,

shutting down the enable needs to be powered on again; if P9-02 is 0, the alarm E-237 (counter

direction reversed) will be output, and the value will be adjusted by power on again.

Incremental serial

communication

Absolute serial communication

5.9.3.3 Speed feedback selection and servo pulse output mode in full closed loop control

Speed feedback selection

in full closed loop control

Loading...

Loading...