61

5.3 Position control

5.3.1 General position control

5.3.1.1 Electronic gear ratio

1. Overview

The so-called "electronic gear" function has two main applications:

(1) Determine the number of command pulses needed to rotate the motor for one revolution to

ensure that the motor speed can reach the required speed.

As an example of 17-bit encoder motor, the pulse frequency sent by the upper computer PLC is

200kHz:

Pulses per revolution set to 10000

Electronic gear ratio set to 131072:10000

Set pulses per revolution to 5000

Electronic gear ratio set to 131072:5000

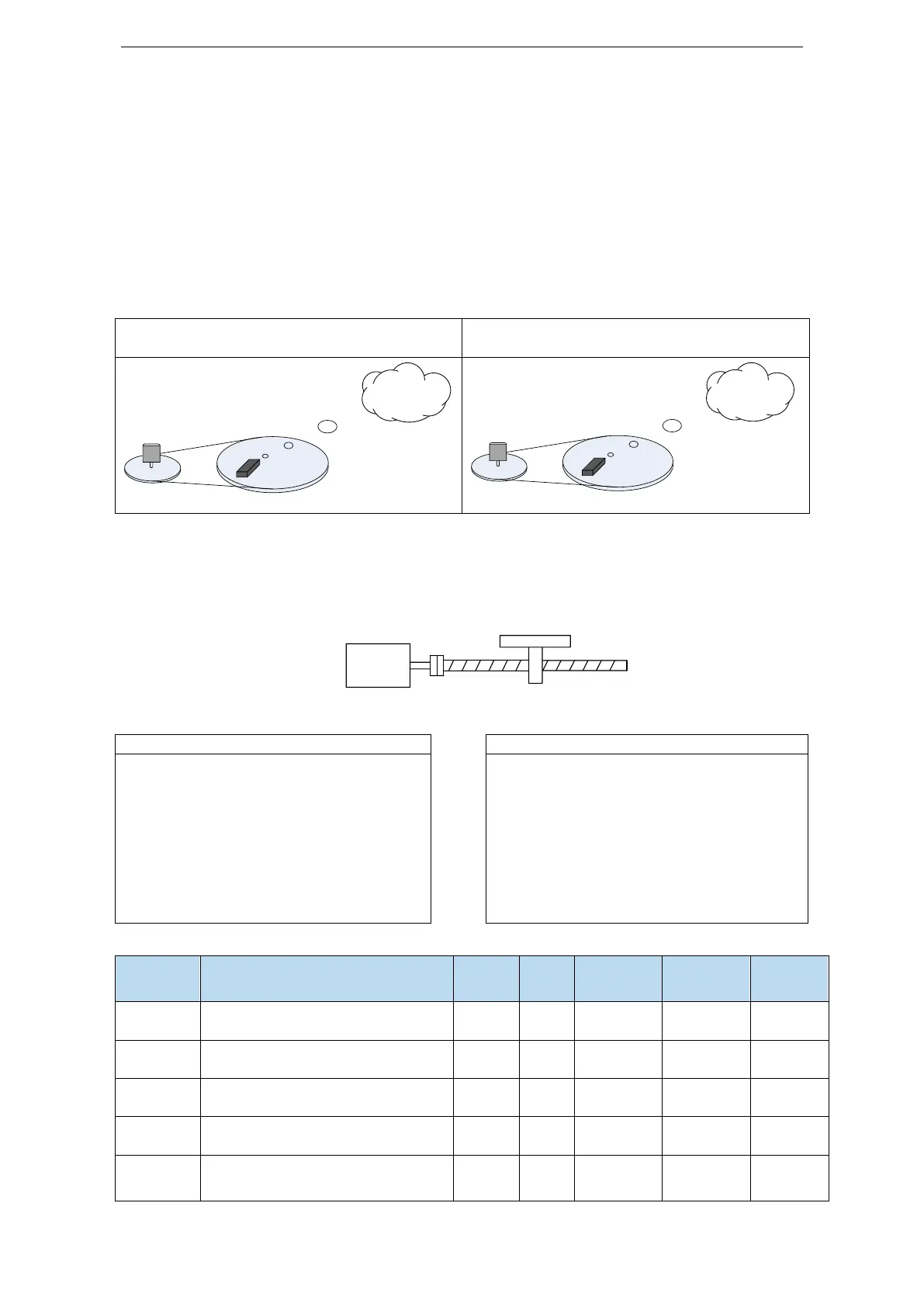

Max speed

600rpm

Two circle radius ratio: 2:1

Big circle run one rotation (need 20000

pulses), small circle run two rotations.

Max speed

1200rpm

Two circle radius ratio: 2:1

Big circle run one rotation (need 10000

pulses), small circle run two rotations.

(2) In the precise positioning, the physical unit length corresponding to 1 command pulse is set for

calculation.

For example: the object moves 1um per command pulse. The command pulses of load rotating one

circle = 6mm / 1um = 6000. In the case of deceleration ratio is 1:1, set pulse per rotation P0-11=6000,

P0-12=0. Then if the PLC outputs 6000 pulses, the object will move 6mm.

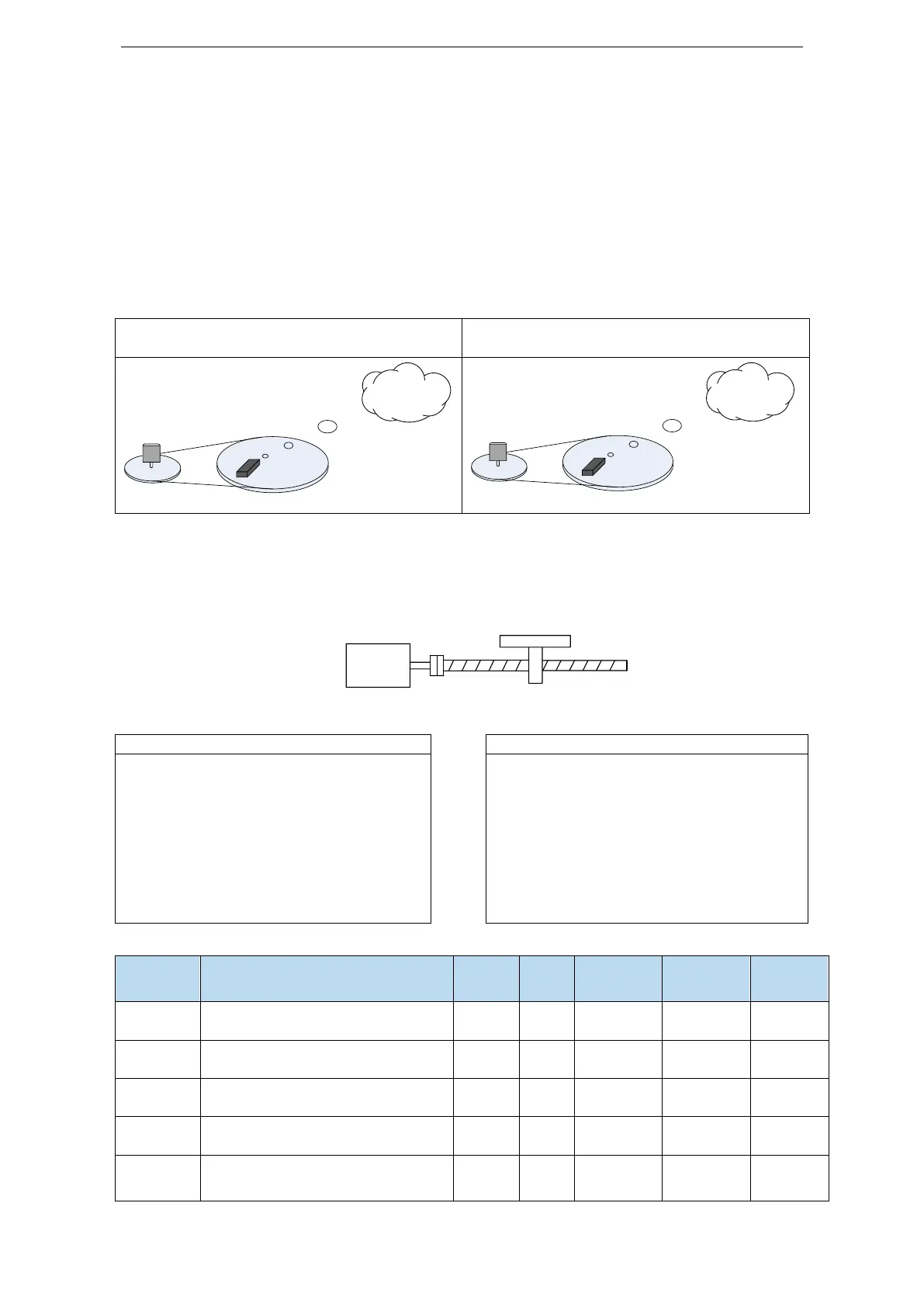

Encoder: 131072(17-bit) ball screw pitch: 6mm

Do not change the electronic gear ratio

Change the electronic gear ratio

Without changing the ratio of the electronic

gear to the motor, the rotating cycle is

131072 pulses (P 0-11=0, P 0-12=0).

If the workpiece is moved 6 mm in one turn,

the number of pulses needed is 131072. If the

workpiece is moved 10 mm, it will need

10/6*131072=218453.333 pulses. When the

decimal number is omitted, the error will

occur.

By changing the electronic gear ratio, the

motor needs 6000 pulses to rotate one circle.

If the workpiece moves 6 mm in one turn, the

number of pulses needed is 6 000. If the

workpiece is moved 10 mm, it needs

10/6*6000 = 10000 pulses. When the pulse is

sent, the decimal number will not be produced

and the error will not be produced.

Related parameters

Pulse numbers per rotation *1

Pulse numbers per rotation *10000

Electronic gear ratio (numerator)

Electronic gear ratio (denominator)

Group 2 Electronic gear ratio

(numerator) low bit*1

Loading...

Loading...