138

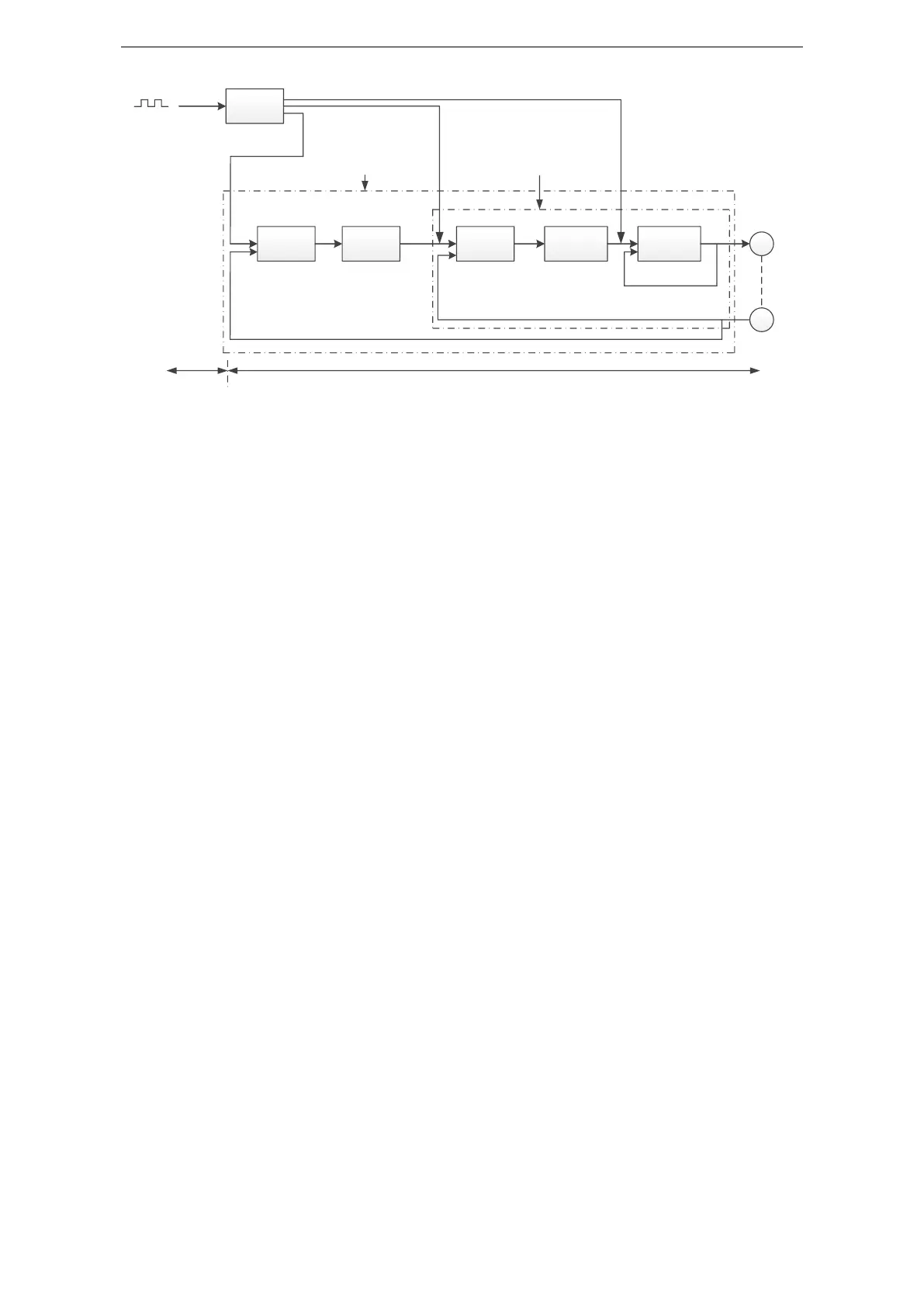

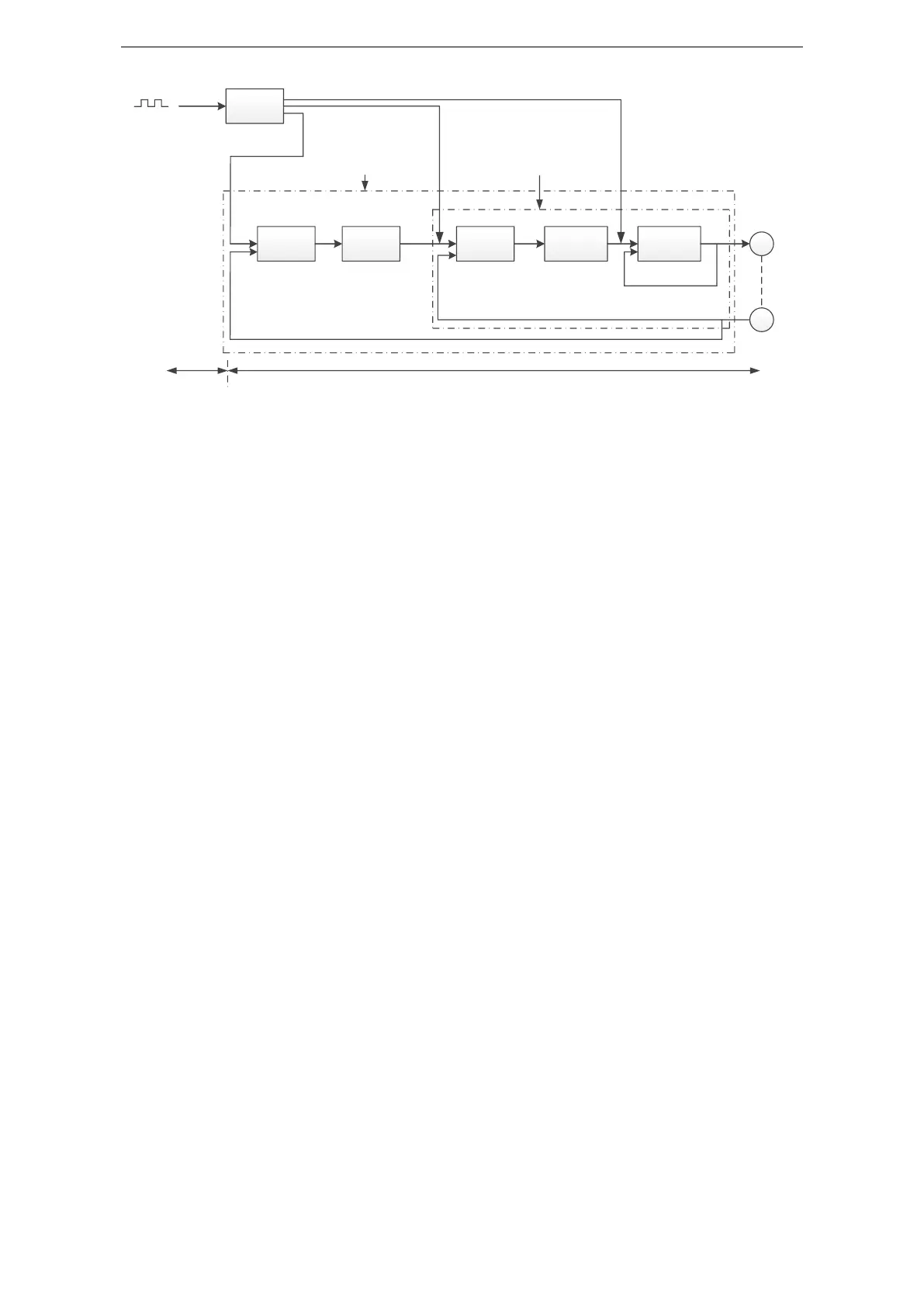

Error

counter

Position

loop gain

Kp

Speed

control Kv,

Ti

Torque

instruction

filter Tf

Current

control

M

PG

Servo motor

encoder

Current loop

Speed loop

Speed

instruction

Position

loop

+

-

+

-

+

-

Pulse instruction

Upper device

Servo unit

Position

control loop

Speed

control loop

Model

loop

Torque

feedforward

Speed

feedforward

Position control loop diagram (turn on the model loop)

Servo unit consists of three feedback loops (current loop, speed loop and position loop) from inside to

outside. The more inner loop, the more responsive it is. Failure to comply with this principle will result

in poor response or vibration. Among them, the current loop parameters are fixed values to ensure

adequate responsiveness, and users do not need to adjust.

Please use manual adjustment in the following occasions:

When the expected effect can not be achieved by fast adjusting the gain

When the expected effect is not achieved by automatically adjusting the gain

6.5.2 Adjustment steps

In position mode, if the soft mode (P2-02.0=1) is selected by auto-tuning, the function of model loop

will be turned off; in speed mode, the gain of position loop will be invalid.

Increasing response time

1. Reducing the filter time constant of torque instruction (P2-35)

2. Increasing Speed Loop Gain (P1-00)

3. Reducing Integral Time Parameter of Speed Loop (P1-01)

4. Increasing the gain of position loop (P1-02)

5. Improving Model Loop Gain (P2-49)

Reduce response, prevent vibration and overshoot

1. Reducing the Speed Loop Gain (P1-00)

2. Increasing Integral Time Constant of Speed Loop (P1-01)

3. Reducing the gain of position loop (P1-02)

4. Increase the filter time constant of the torque instruction (P2-35)

5. Reducing Model Loop Gain (P2-49)

6.5.3 Gain parameters for adjustment

The gain parameters that need to be adjusted:

P1-00 Speed Loop Gain

P1-01 Integral Time Constant of Speed Loop

P1-02 position loop gain

P2-35 Torque Instruction Filtering Time Constant

P2-49 Model Loop Gain

Loading...

Loading...