62

Group 2 Electronic gear ratio

(numerator) high bit*10000

Group 2 Electronic gear ratio

(denominator) low bit*1

Group 2 Electronic gear ratio

(denominator) high bit*10000

Note:

(1) P0-11~P0-14 is all about the parameters of electronic gear ratio, P0-11, P0-12 is group 1, P0-13,

P0-14 is group 2, but the priority of P0-11 and P0-12 is higher than that of P0-13 and P0-14. Only

when P0-11 and P0-12 are set to 0, the ratio of electronic gear P0-13 and P0-14 will take effect.

(2) When P0-11, P0-12, P0-13 and P0-14 are all set to 0, P0-92, P0-93, P0-94 and P0-95 will take

effect.

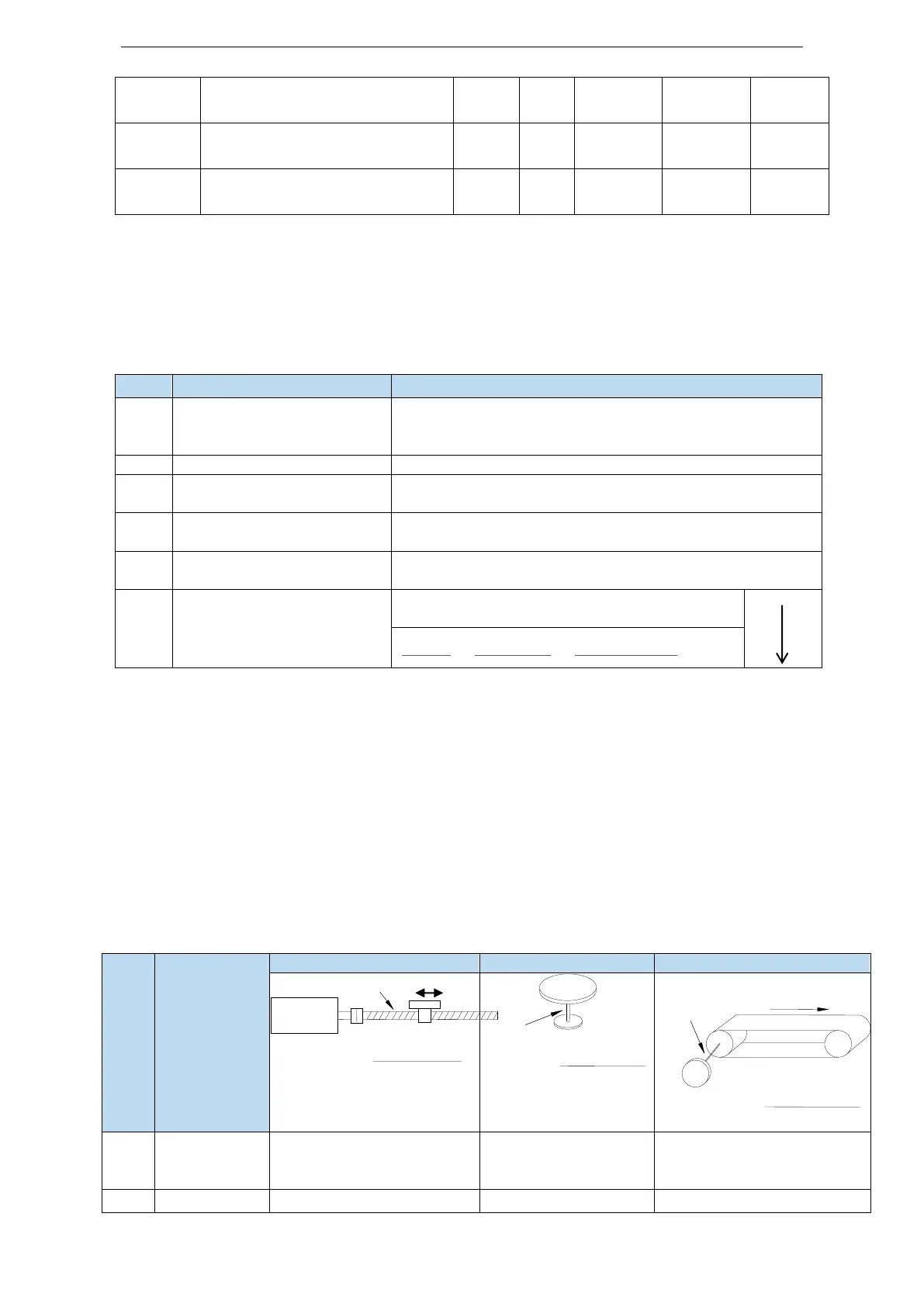

2. Calculation of Pulse Number per Rotation and Electronic Gear Ratio

Confirm the machine

specification

Confirm the deceleration ratio n:m(servo motor turns m

rotations while load turns n rotations), ball screw distance,

pulley diameter.

Confirm the encoder pulse

Confirm the servo motor encoder accuracy

Determine the actual distance or angle corresponding to 1

pulse of the controller

Calculate the command pulses

the load shaft rotates 1 circle

Based on the determined command unit, calculate the

command quantity n of the load shaft rotating for 1 revolution.

Calculate the pulses per

rotation M

Command pulse number of motor shaft rotating for 1 turn

M=N/(m/n).

Set the pulses per rotation

(P0-11/P0-12) or

Electronic gear ratio

(P0-13/P0-14)/(P0-92~95)

nN

m

M140P

130P

resolution

encoder

resolution

encoder

Note:

(1) In step 6, the effective priority of the number of pulses per revolution is higher than the

electronic gear ratio, that is, when P0-11 ~ P0-12 are all 0, P0-13 ~ P0-14 will take effect. In special

cases, if the number of pulses per revolution is calculated as a decimal, the electronic gear ratio should

be considered.

(2) When P0-13 and P0-14 exceed the setting range, please divide the electronic gear ratio into

numerator and denominator. If the ratio still exceeds the parameter setting range, please use the second

gear ratio P0-92~P0-95. Only when P0-11~14 = 0, the second gear ratio takes effect.

(3) The resolution of DS5 series servo motor encoder is 131072 (17 bits) and 8388608 (23 bits).

(4) The command unit does not represent the machining accuracy. On the basis of the mechanical

accuracy, refining the instruction unit quantity can improve the positioning accuracy of the servo

system. For example, when using the lead screw, the mechanical accuracy can reach 0.01mm, so the

unit equivalent of 0.01mm is more accurate than the unit equivalent of 0.1mm.

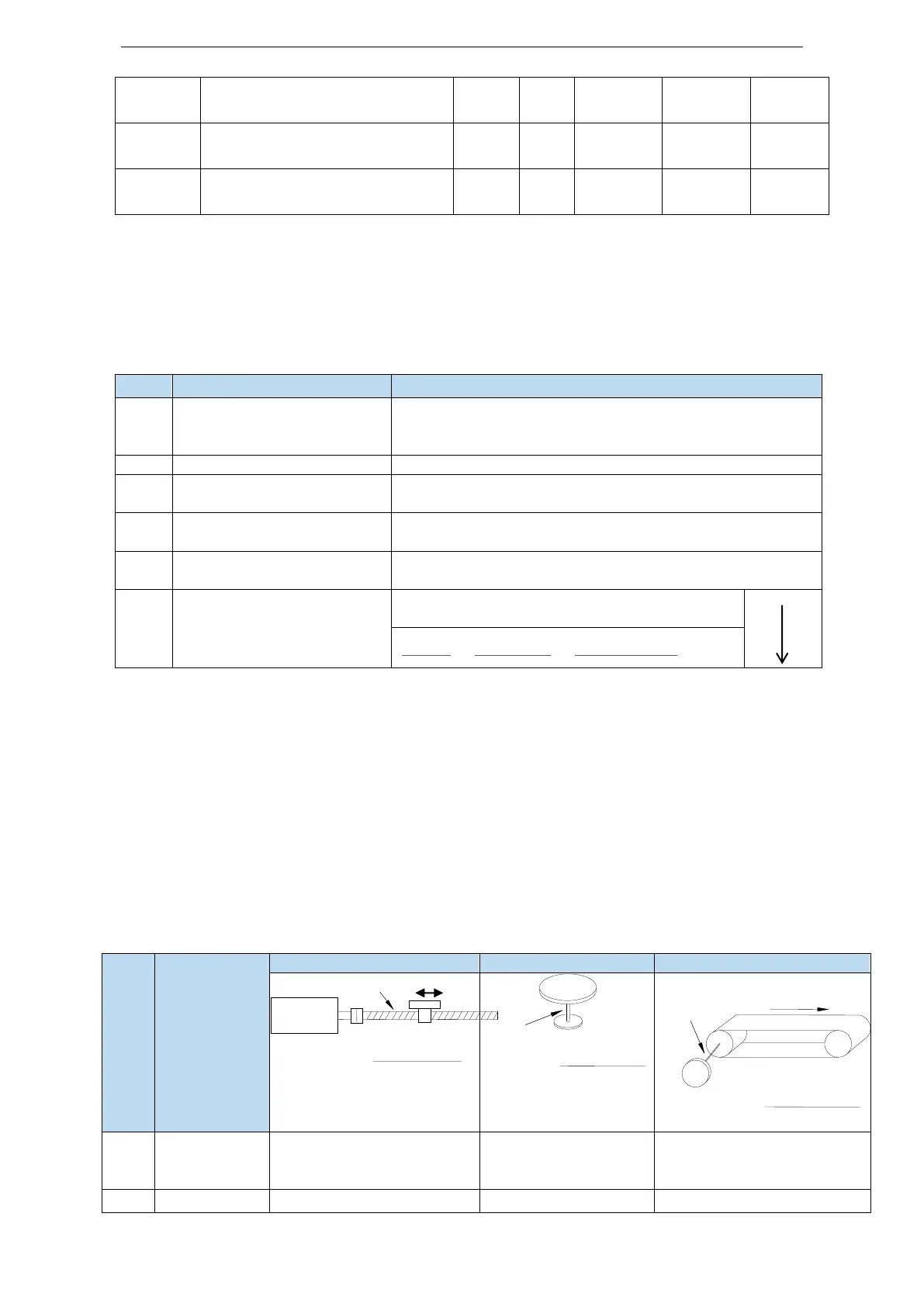

3. Example of setting the electronic gear ratio

Confirm

mechanical

specifications

Ball screw pitch: 6mm

Machine deceleration ratio:

1:1

1-circle rotate angle:

360°

Encoder resolution 131072

Encoder resolution 131072

Loading...

Loading...