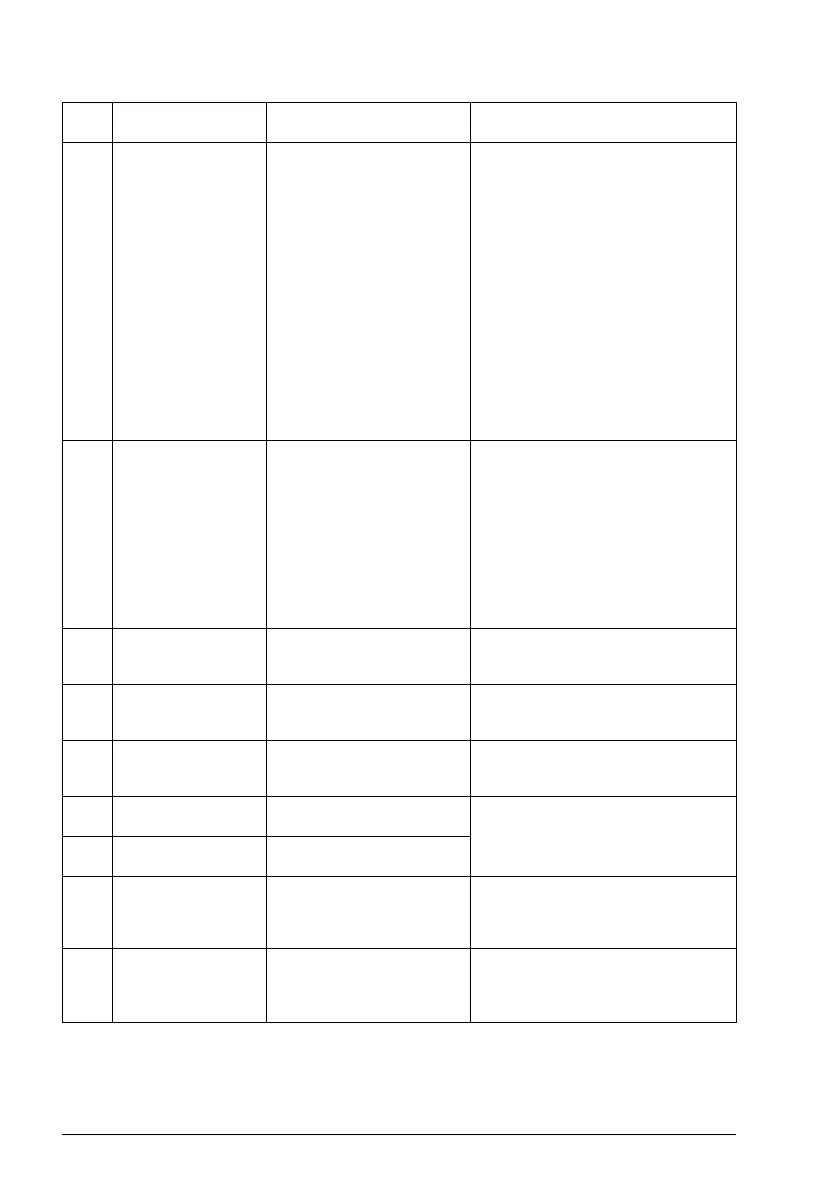

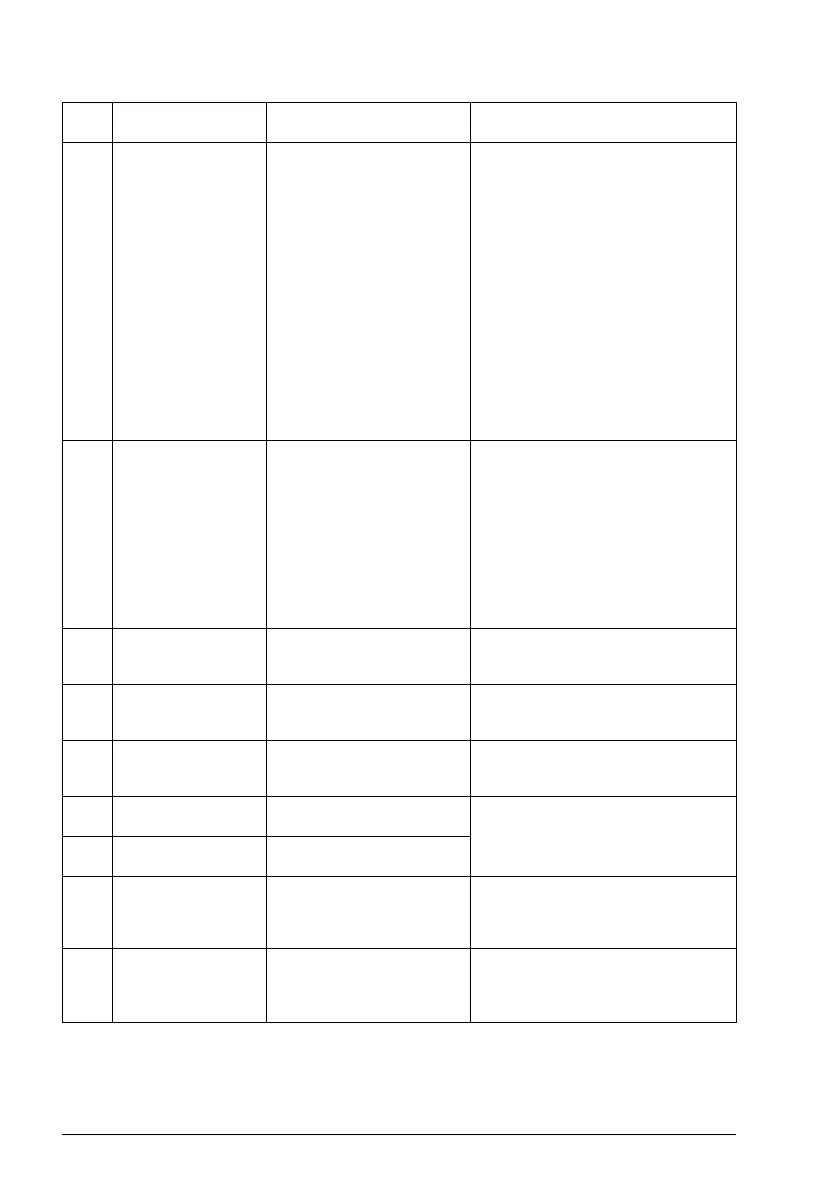

576 Fault tracing

A6DA Reference source

parametrization

A reference source is

simultaneously connected to

multiple parameters with

different units.

Check the reference source selection

parameters.

Check the auxiliary code (format

XXYY 00ZZ). “XX” and “YY” specify the

two sets of parameters where the source

was connected to (01 = speed reference

chain [22.11, 22.12, 22.15, 22.17], 02 =

frequency reference chain [28.11, 28.12],

03 = torque reference chain [26.11,

26.12, 26.16], 04 = other torque-related

parameters [26.25, 30.21, 30.22, 44.09],

05 = process PID control parameters

[40.16, 40.17, 40.50, 41.16, 41.17,

41.50]). “ZZ” indicates the conflicting

reference source (01…0E = index in

parameter group 3, 33 = process PID

control, 3D = motor potentiometer, 65 =

AI1, 66 = AI2, 6F = frequency input).

A6E5 AI parametrization The current/voltage hardware

setting of an analog input does

not correspond to parameter

settings.

Check the auxiliary code. The code

identifies the analog input whose settings

are in conflict.

Adjust either the hardware setting (on the

drive control unit) or parameter

12.15/12.25.

Note: Control board reboot (either by

cycling the power or through parameter

96.08 Control board boot) is required to

validate any changes in the hardware

settings.

A6E6 ULC configuration User load curve configuration

error.

Check the auxiliary code (format XXXX

ZZZZ). “ZZZZ” indicates the problem

(see actions for each code below).

0000 Speed points inconsistent. Check that each speed point (parameters

37.11…37.15) has a higher value than

the previous point.

0001 Frequency points inconsistent. Check that each frequency point

(37.16…37.20) has a higher value than

the previous point.

0002 Underload point above

overload point.

Check that each overload point

(37.31…37.35) has a higher value than

the corresponding underload point

(37.21…37.25).

0003 Overload point below

underload point.

A780 Motor stall

Programmable warning:

31.24 Stall function

Motor is operating in stall

region because of e.g.

excessive load or insufficient

motor power.

Check motor load and drive ratings.

Check fault function parameters.

A781 Motor fan

Programmable warning:

35.106 DOL starter event

type

No feedback received from

external fan.

Check external fan (or other equipment

controlled) by the logic.

Check settings of parameters

35.100…35.106.

Code

(hex)

Warning Cause What to do

Loading...

Loading...