11.0 CS20 - TWO LOOP CONTROLLER

11.1 CS20 - TWO LOOP CONTROLLER

A two loop 53MC5000 Controller is configured at the factory for CS20 operation to provide the

standard displays listed in Table 11-2 and the default datapoint settings listed in Table 11-3. As a

Two Loop (PID) Controller, each loop Proportional Band is set at 100%; the Process Variables AI0-

1 are scaled 0-100% for linear 4-20 mA input signals; and AO0-1 are set as reverse action (PV

above setpoint causes decreasing value) control signals over a 4-20 mA signalling range. These

settings may be altered and additional Control Strategy 20 (CS20) functions can be activated as ne-

cessitated by the process application. The Two Loop Controller provides two identical standard

PID controllers with both control loops fully independent of each other. The input/output signals for

the two control loops are identical: Process Variable (PV), Remote Setpoint, Remote Setpoint En-

able, Control Output, and Process Alarms.

Just as with the standard Single Loop (PID) Controller,

only the Process Variable and Control Output of each loop are required for control purposes; the

other signals do not have to be connected or configured

. Each loop calculates an output from the

difference between its Process Variable feedback signal sent from a Field Transmitter (FT) (e.g,

flow meter) and its setpoint (SP) value. After the output is calculated, it is applied to a final control

loop element (e.g, valve) to restore process flow to the loop setpoint value.

Validate the controller

model number to ensure it has the necessary two loop hardware capabilities.

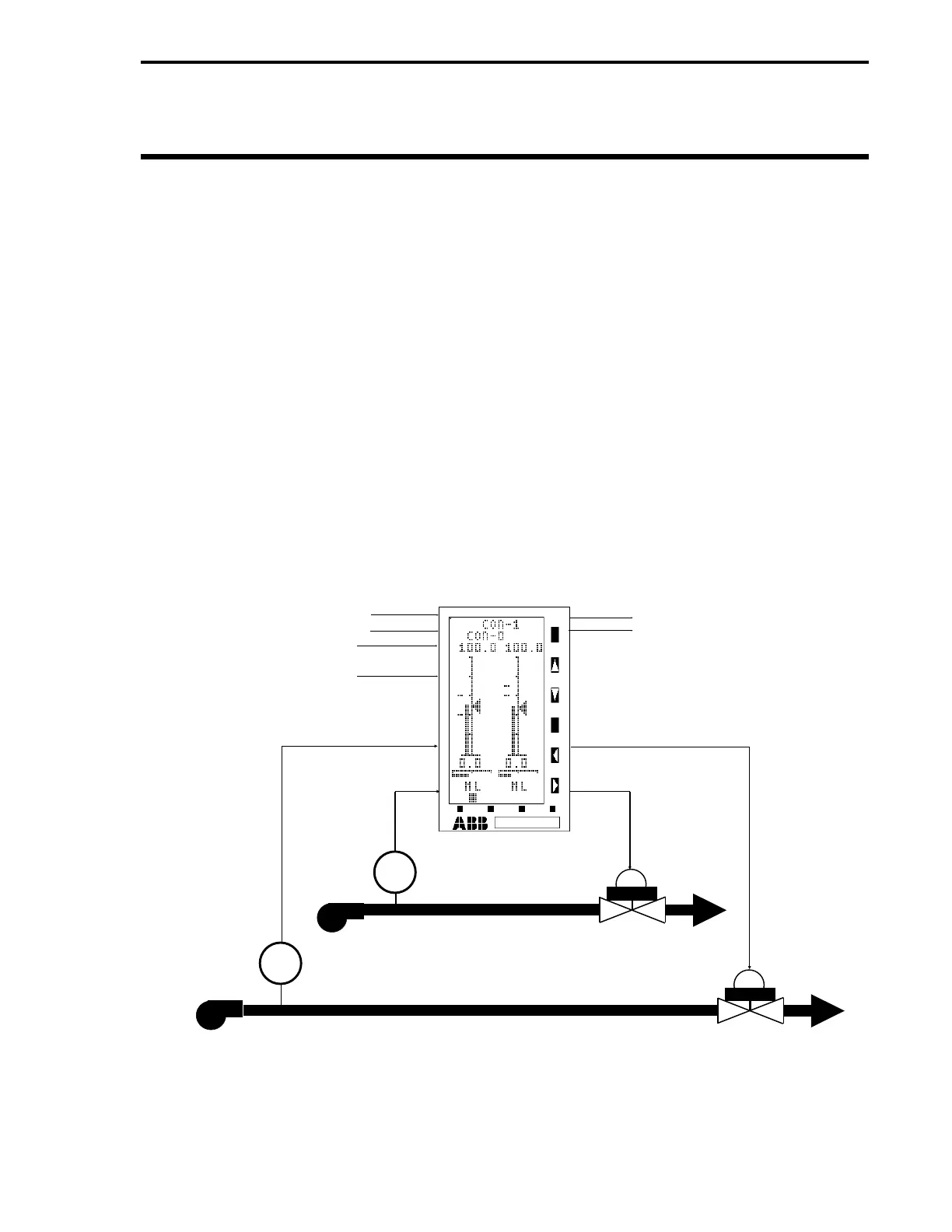

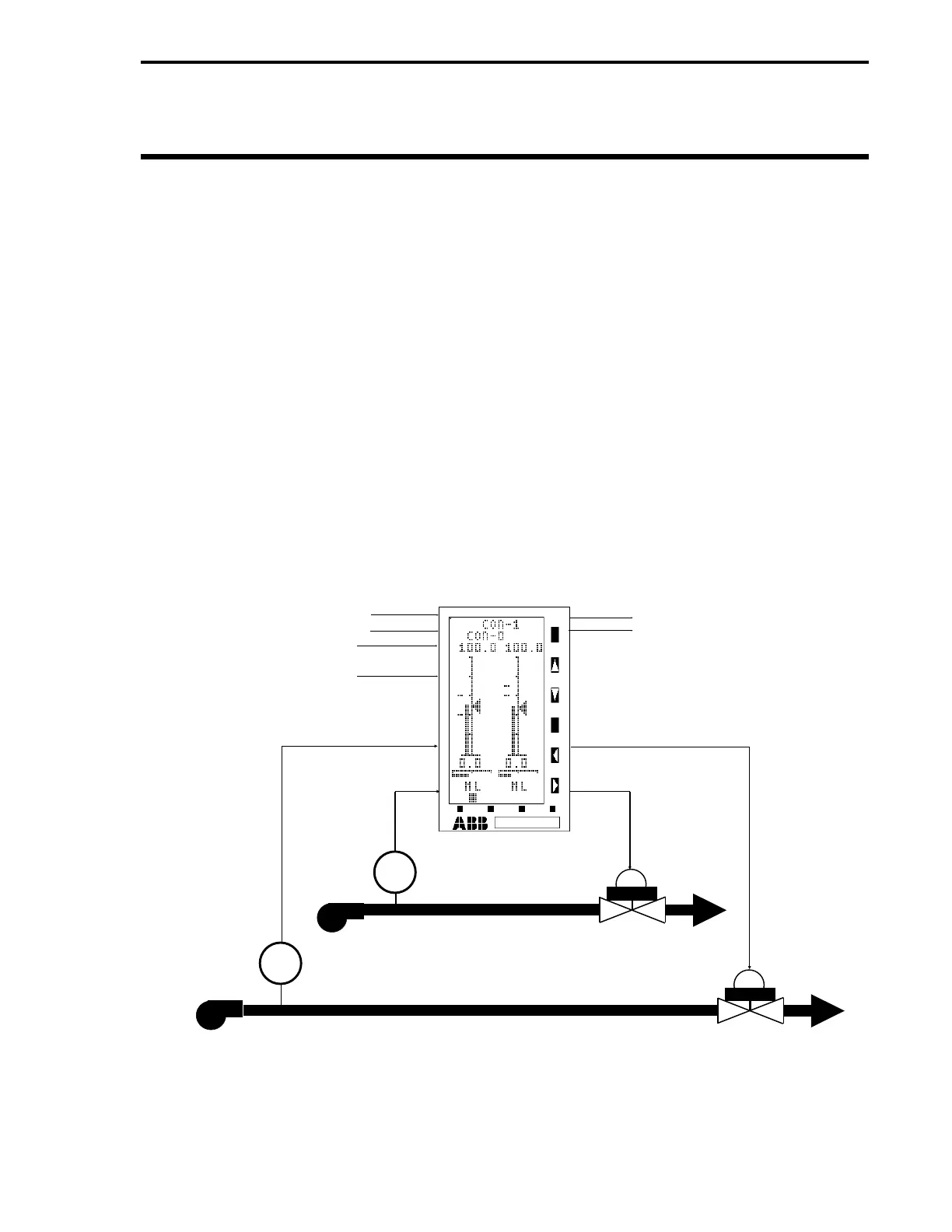

A typical low-resolu-

tion display Two Loop Controller process application is illustrated in Figure 11-1.

Figure 11-1. Typical CS20 Two Loop Controller Application

PUMP

VALVE

LOOP 1

PUMP

VALVE

LOOP 2

FT

AI2 - REMOTE SETPOINT LOOP 1

AI3 - REMOTE SETPOINT LOOP 2

DI0 - REMOTE ENABLE LOOP 1

(CLOSED CONTACT)

DI1 - REMOTE ENABLE LOOP 2

(CLOSED CONTACT)

AI1 - PROCESS

VARIABLE LOOP 2

AI0 - PROCESS

VARIABLE LOOP 1

DO0 - PROCESS ALARMS LOOP 1

DO1 - PROCESS ALARMS LOOP 2

AO1 - CONTROL

OUTPUT LOOP 2

AO0 - CONTROL

OUTPUT LOOP 1

FT

Section 11. CS20 - Two Loop Controller

11-1

Loading...

Loading...