Chapter 2 - Safety

22 Adept Cobra s600/s800 Robot User’s Guide, Rev H

2.2 Warning Labels on the Robot

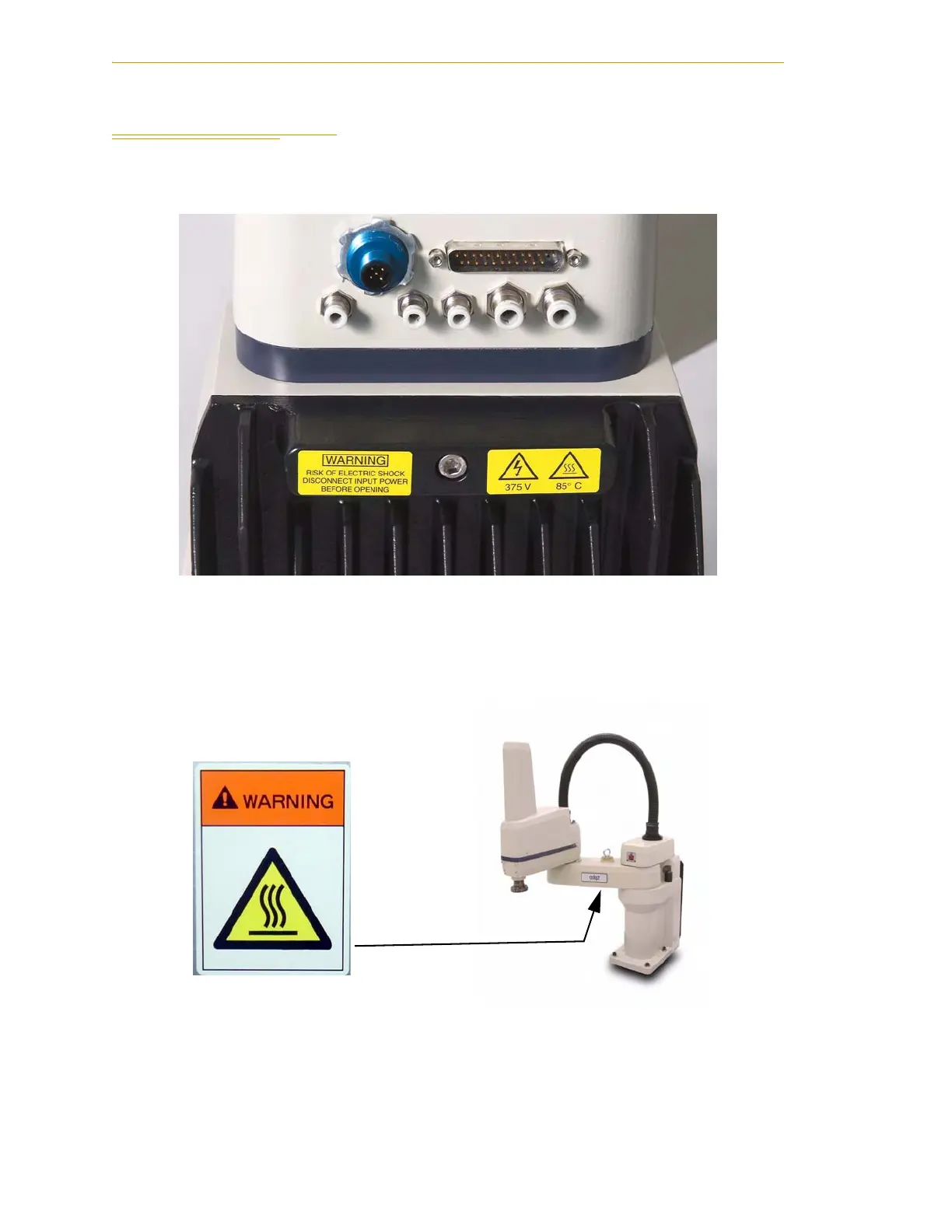

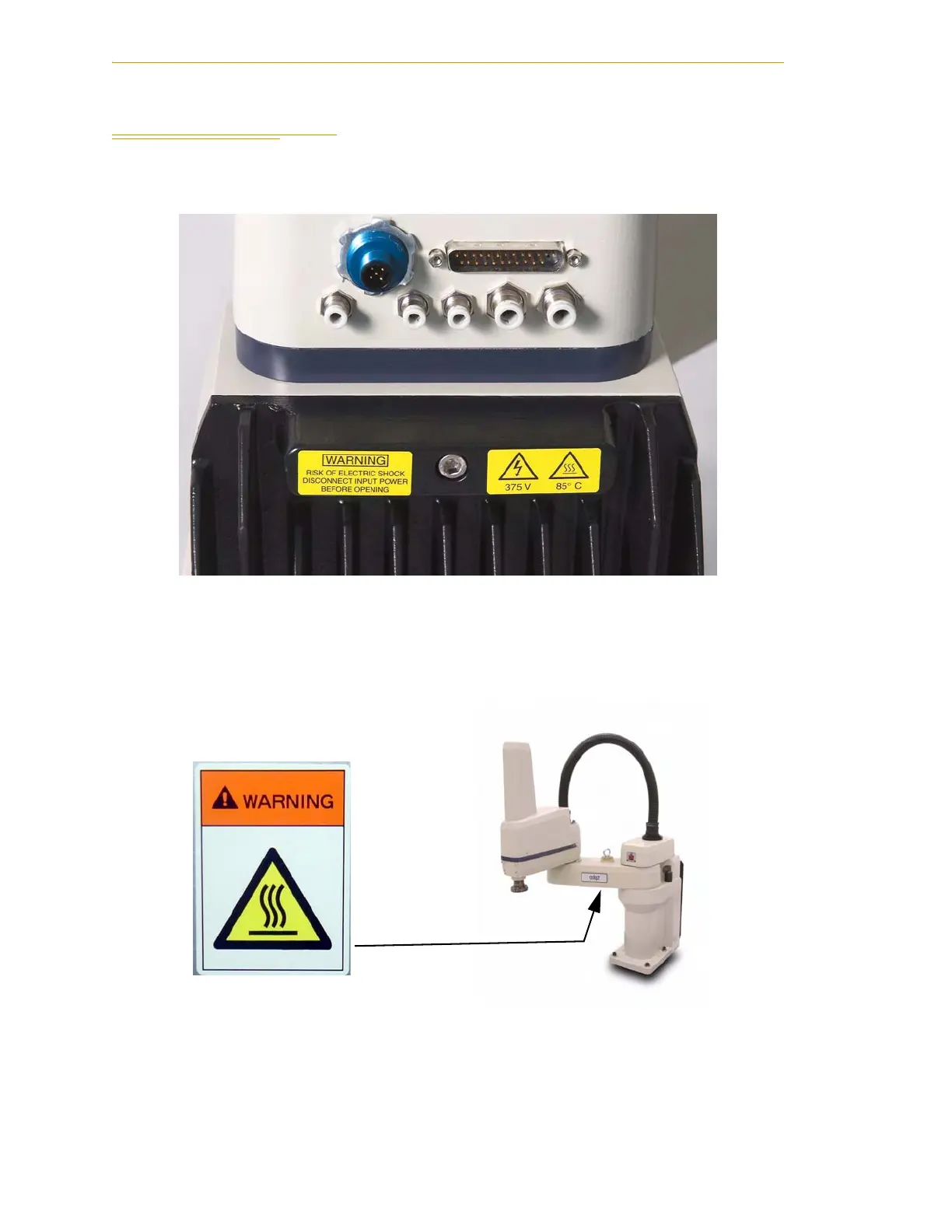

The following two figures show the warning labels on the Adept Cobra s-series robots.

Figure 2-1. Electrical and Thermal Warning Labels on AIB Chassis

Figure 2-2. Thermal Warning Label on Underside of Inner Link

Loading...

Loading...