H Marking

grooves pcs

Order

number

9.03+0.02 - (std.) 8368 67048

9.08+0.02 1 8368 67050

9.13+0.02 2 8368 67051

9.23+0.02 3 8368 67052

Cylinder liners with oversize flanges (higher

flanges) have grooves as a mark on the outer

circumference as follows:

• 1st oversize, 0.05 mm = 1 groove

• 2nd oversize, 0.10 mm = 2 grooves

• 3rd oversize, 0.20 mm = 3 grooves

NOTE: 33-74 engines: Recess depth is

adjusted with a cylinder liner recess cutter

9101 65600.

NOTE: 84-98 engines: Recess depth is

adjusted with a cylinder liner recess cutter

9104 52000.

9.

Check the cylinder liner flange and the

cylinder block recess depth, if the cylinder

liner height is not the same all the way

round.

10.

Replace the cylinder liner, if the cylinder liner

flange has any fault.

11.

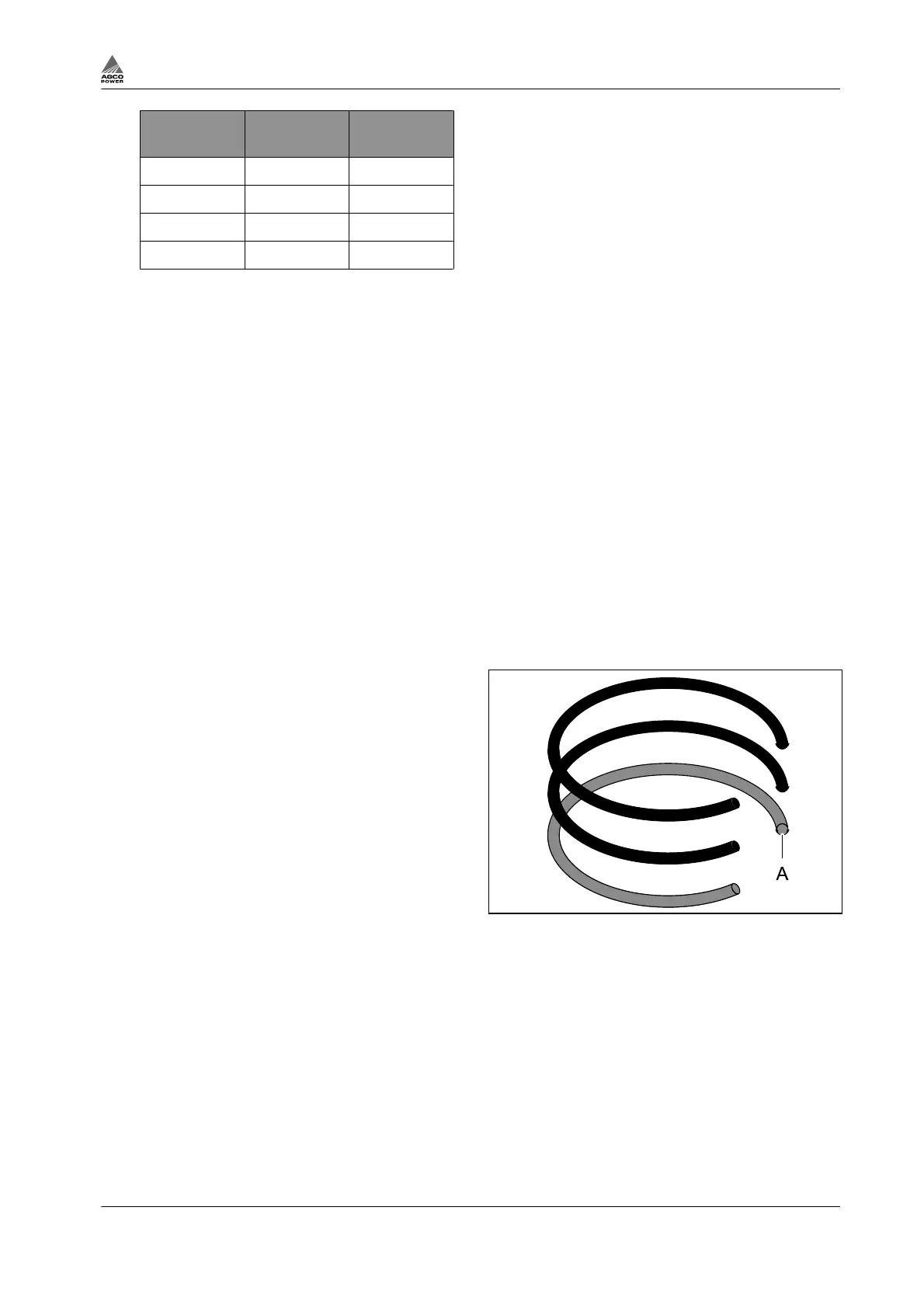

Fit the O-rings.

a)

b) 33-74 engines: Fit the O-rings into the

grooves in the cylinder liner.

c) 84-98 engines: Fit the O-rings into the

grooves in the cylinder block.

d) Fit the green O-ring (A) into the bottom

groove.

e) Lubricate the O-rings with a liquid soap

(not with engine oil).

NOTE: Extend the O-rings as little as

possible when fitting the O-rings. Maximum

permitted stretch is 6%.

Fig. 13

3. Maintenance

4th Generation Engines 3-11

8370 79492

Loading...

Loading...