xvii

Cutting flammable materials

C

hips of titanium or magnesium violently burn when they catch fire.

Once these chips burn, the resultant fire may explosively propagate

through surrounding chips. When an oil-based cutting fluid is used on

the machine, it may also be ignited and spread the fire.

When cutting such flammable materials, be sure to clean the machine

of accumulated chips at the start and end of every operation. During

automatic operation, stop the machine as required to remove the chips.

Take care so that the cutting fluid is discharged in a sufficient amount

during the cutting operation.

When cutting a flammable material, be sure to prohibit any use of fire in

the shop, install a fire extinguisher or other fire control device near the

machine. Never leave the machine unattended during the cutting

operation.

When carrying or disposing of chips, take due care so that they do not

catch fire. Be sure to prohibit any use of fire where the chips are

stored.

Cutting unknown materials

Before cutting an unknown material, consult the supplier of the material,

burn a small amount of chips from the material in a safe place, or follow

any other procedure to check to see if the material is flammable or not.

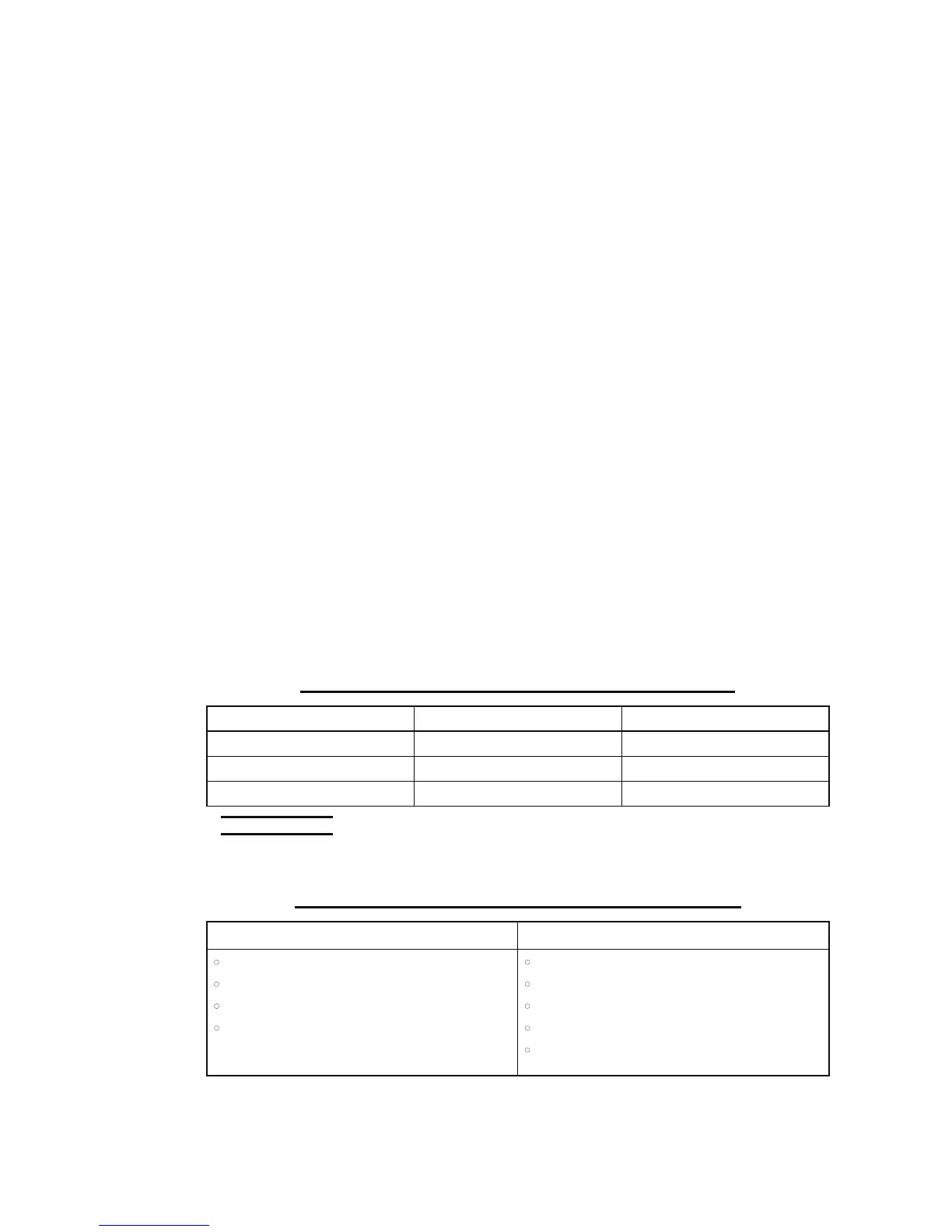

Appendix 1: Classification of water-soluble cutting fluids

Color when diluted Main composition

Soluble Milky white or clear Mineral oil

Semi-synthetic Clear Mineral oil

Synthetic Clear Polymer

NOTE

O Dilute each product to the specified ratio.

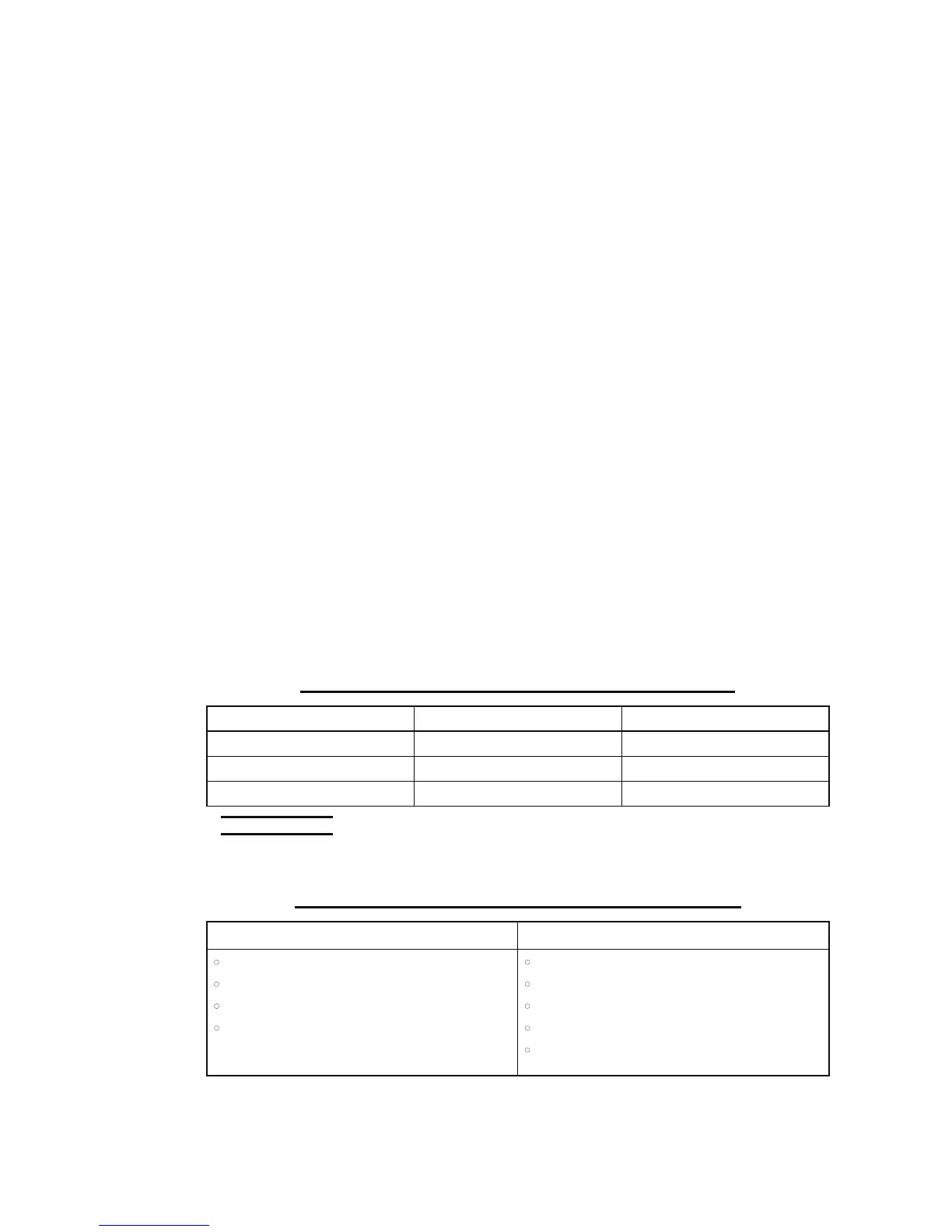

Appendix 2: Characteristics of water-soluble cutting fluids

Advantage Disadvantage

x Have high cooling effect

x Not flammable

x Economical

x Do not require cleaning of cut products

(especially when soluble)

x Remove paint

x Lose rust protection effect when deteriorated

x Foam

x Putrefy

x

Decline in performance, depending on quality of

water used for dilution

Loading...

Loading...