SECTION 5 – INSTALLATION INSTRUCTIONS

UL EX3470 ULC EX3470

2014-SEP-01 REV. 11 PAGE 5-7

R-102 Restaurant Fire Suppression Manual

AGENT DISTRIBUTION HOSE INSTALLATION

INSTRUCTIONS (Continued)

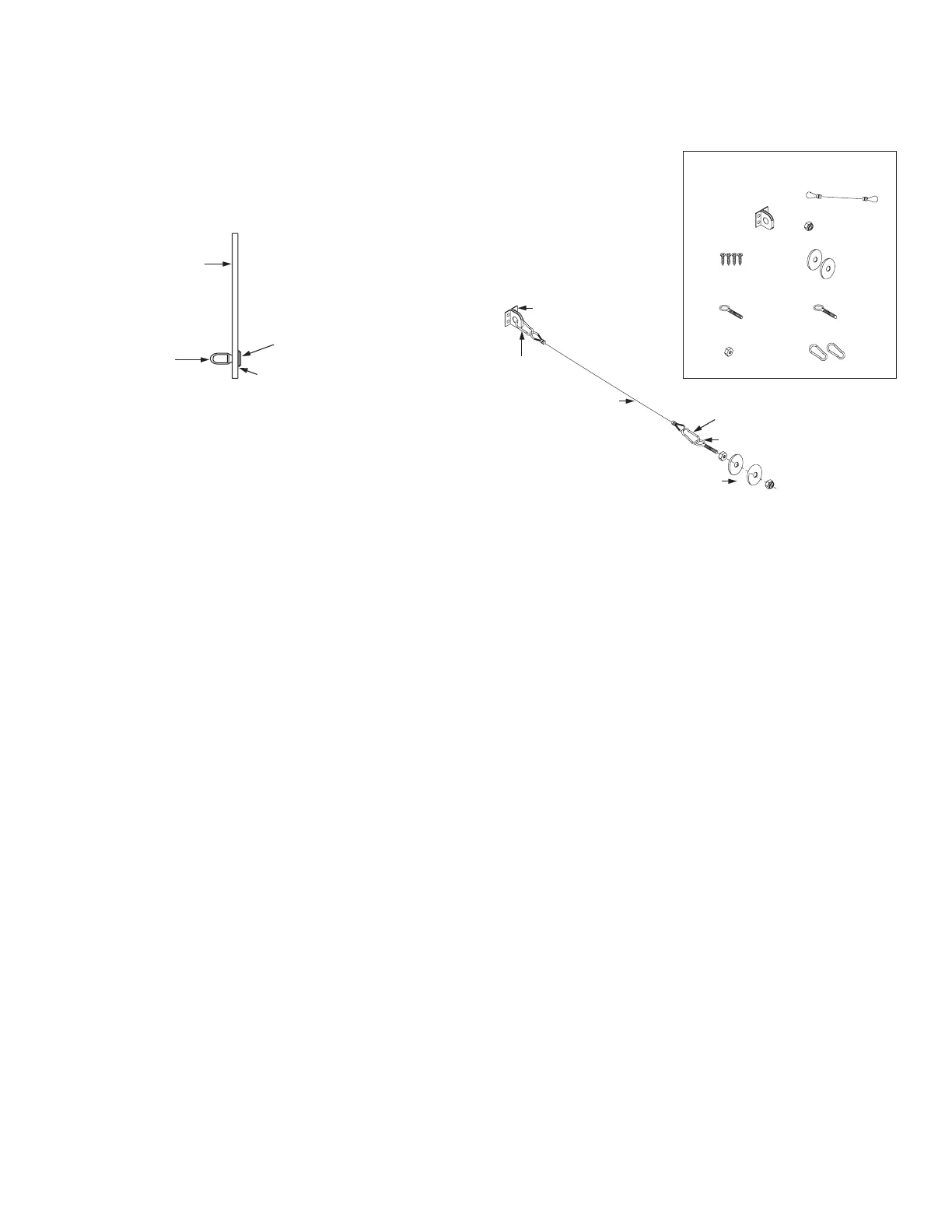

Restraining Cable Installation (Continued)

WASHER

BACK OF

APPLIANCE

EYE

NUT

PHILIPS

SCREW

RESTRAINING CABLE – HENNY PENNY-MOUNTED OPTION

FIGURE 5-12

008090

1. The Restraining Cable must be connected from the appli-

ance to the wall or some other structurally sound object

capable of restraining the castered appliance from being

able to be pulled or pushed out to a point that will result in

strain or stress to the Agent Distribution Hose.

2. The Restraining Cable should be installed in line with the

Agent Distribution Hose.

3. For sheet metal covered walls, the Restraining Cable

Assembly includes four 3/4 in. x #8 self tapping sheet

metal screws, and a Restraining Cable Bracket. Securely

attach the Restraining Cable Bracket to the sheet metal

covered wall using the 3/4 in. x #8 self tapping metal screws

provided.

4. For mounting to wall studs, the Restraining Cable Assembly

includes one screw eye lag bolt, 5/16 in. x 2.5 in. (64 mm) long.

5. Locate a structural area (frame) on the rear side of the

equipment that is in line with the wall attachment. Note: It

may be necessary to contact the appliance manufacturer for

a suitable location. Drill a 5/16 in. (7.9 mm) diameter hole.

Use caution when drilling hole, so that internal components

are not damaged.

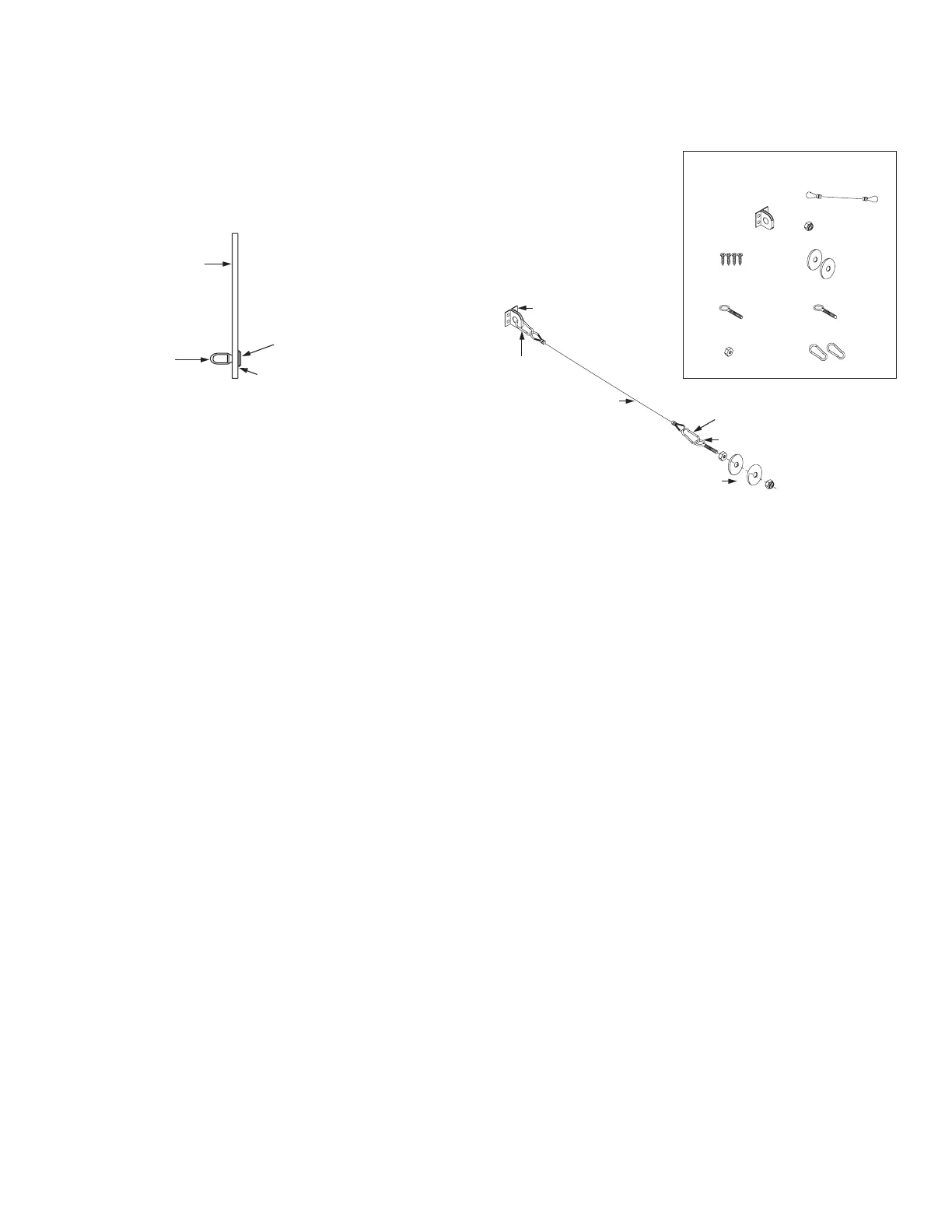

6. The Restraining Cable Assembly also includes a 5/16 in.

threaded eye-bolt, 5/16 in. hex head nut, 5/16 in nylon lock

nut, and two 5/16 in. flat washers. Thread the included hex

nut onto the eye-bolt. Slide one washer onto the eye-bolt

threads next to the nut. Then, slide the eye-bolt through

the drilled hole and place a washer and nylon locknut onto

the eye-bolt on the inside frame of the equipment. Tighten

securely.

7. Attach one of the snap hooks (included in the Restraining

Cable package) on the end of the Restraining Cable to the

wall bracket and the other snap hook to the eye-bolt (See

Figure 5-13). After snap-hooking the assembly, seal the

Restraining Cable Loops to the wall bracketry and appliance

connection hardware with Lead Wire Seal (Part No. 197).

Note: For the Henny Penny Pressure Fryers that utilize the

ANSUL Henny Penny Fryer Nozzle Kit, Part No. 434455,

the 5/16 in. philips screw supplied in the Henny Penny

Fryer Nozzle Kit, the 5/16 in. eye nut, and 5/16 in. washer

included in the Restraining Cable Assembly Kit, must be

used. (See Figure 5-12).

RESTRAINING CABLE

INSTALLATION PACKAGE

E – 5/16 IN HEX NUT

A – RESTRAINING CABLE

F – 5/16 IN NYLON

LOCK NUT

G – 5/16 IN

X 5/16 IN

WASHERS

(2)

B – STAPLE

BRACKET

C – 3/4 IN. X #8

SCREWS (4)

H – SCREW

EYE BOLT

I – SNAP

HOOK

D – EYE BOLT

B – STAPLE BRACKET

D – EYE BOLT

I – SNAP HOOK

I – SNAP

HOOK

EYE BOLT FASTENING

HARDWARE

A – RESTRAINING

CABLE

FIGURE 5-13

007829

Final Installation Guidelines and Checkout Procedures

After the Agent Distribution Hose and the Restraining Cable is

properly installed, carefully push the appliance back to its normal

operating position. Check that the hose does not have sharp

bends, and is not kinked, twisted, or caught on anything behind

the appliance.

1. Verify the Restraining Cable limits the travel of the appli-

ance and prevents the application of any pull force or

bending stress on the Agent Distribution Hose or hose-to-

pipe connections.

2. Make certain there are no sharp bends and kinks in the

hose when pulling out the cooking equipment.

3. The Agent Distribution Hose should always be in a vertical

natural loop, never having any bends greater than a 3 in.

(76 mm) radius (6 in. (152 mm) diameter), hose twists, or

sharp bends. (See Figure 5-14.) If any of these conditions

exist, the hose and/or hose connections will require installa-

tion modifications.

Loading...

Loading...