SECTION 4 – SYSTEM DESIGN

UL EX3470 ULC EX3470

PAGE 4-52 REV. 11 2014-SEP-01

R-102 Restaurant Fire Suppression Manual

SPECIFIC APPLICATION BY MODEL (Continued)

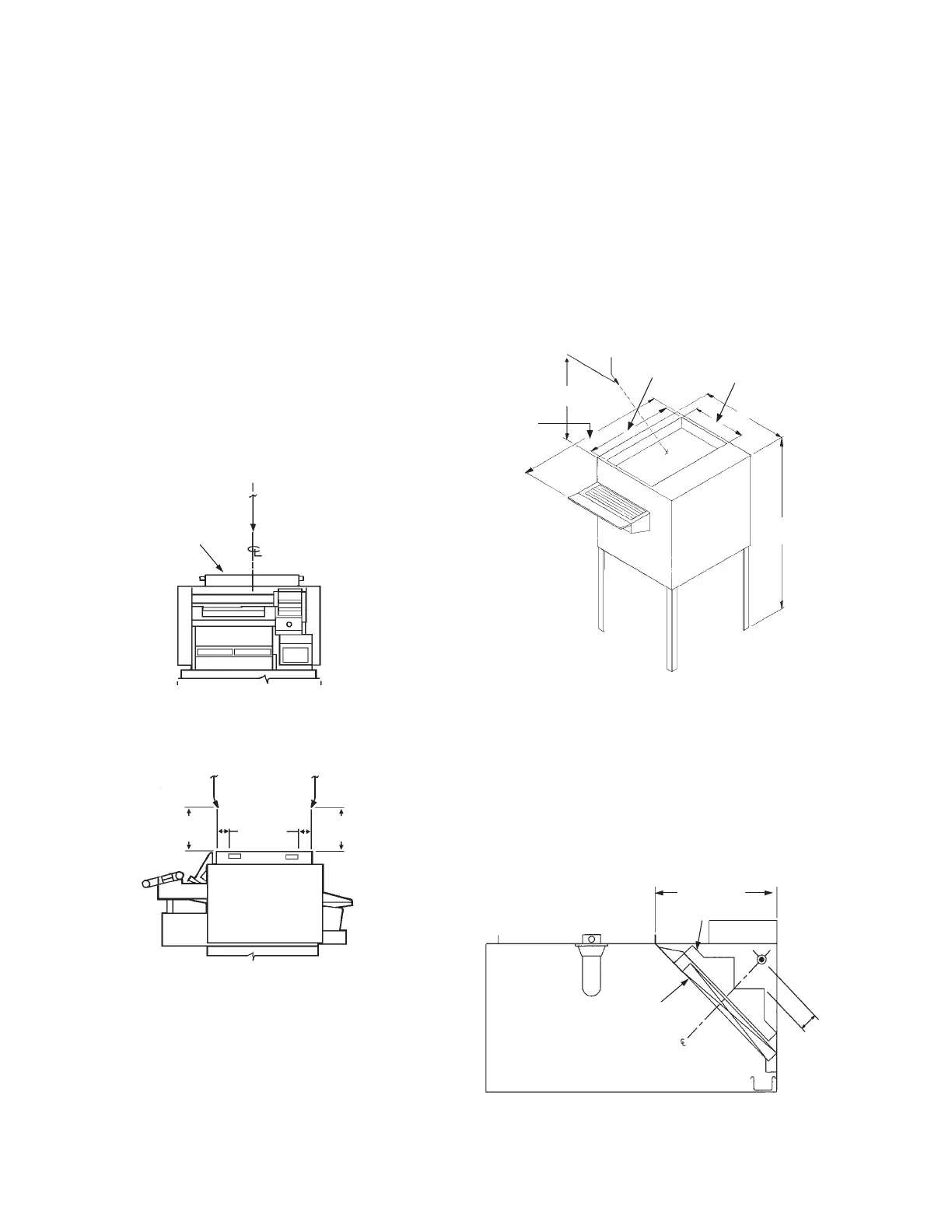

Marshall Air – Model 2001BK Multi-Chamber Broiler

• Nozzle Quantity/Type: Two 1W nozzles

• Nozzle Location: Front nozzle tip must be located 14 in.

(355 mm) directly above the appliance, aligned with the front

face and centerline of the catalytic converter. The aim point is

4 in. (101 mm) forward of the front edge of the converter on

the centerline.

The rear nozzle tip is a mirror image of the front. The rear

nozzle is located 14 in. (355 mm) vertically above the appli-

ance, aligned with the “rear” face and centerline of the cata-

lytic converter. The aim point is 4 in. (101 mm) behind the

“rear” edge of the converter on the centerline. See Figure

4-102.

• System Limitation: Maximum of ve ows for a 3.0 gallon

system: Remaining ow points available may be used to

protect other hazards.

TWO 1W NOZZLES

003418a

CONVERTER

FRONT VIEW

CENTERED ON CONVERTER

NOZZLE ALIGNED WITH

FRONT OF CONVERTER,

AIMED 4 IN. (101 mm) BACK

NOZZLE ALIGNED WITH BACK

OF CONVERTER, AIMED

4 IN. (101 mm) FORWARD

1W

NOZZLE

1W

NOZZLE

4 IN.

(101 mm)

003418B

SIDE VIEW

NOZZLE ALIGNED WITH FRONT OF CONVERTER

14 IN.

(355 mm)

14 IN.

(355 mm)

FIGURE 4-102

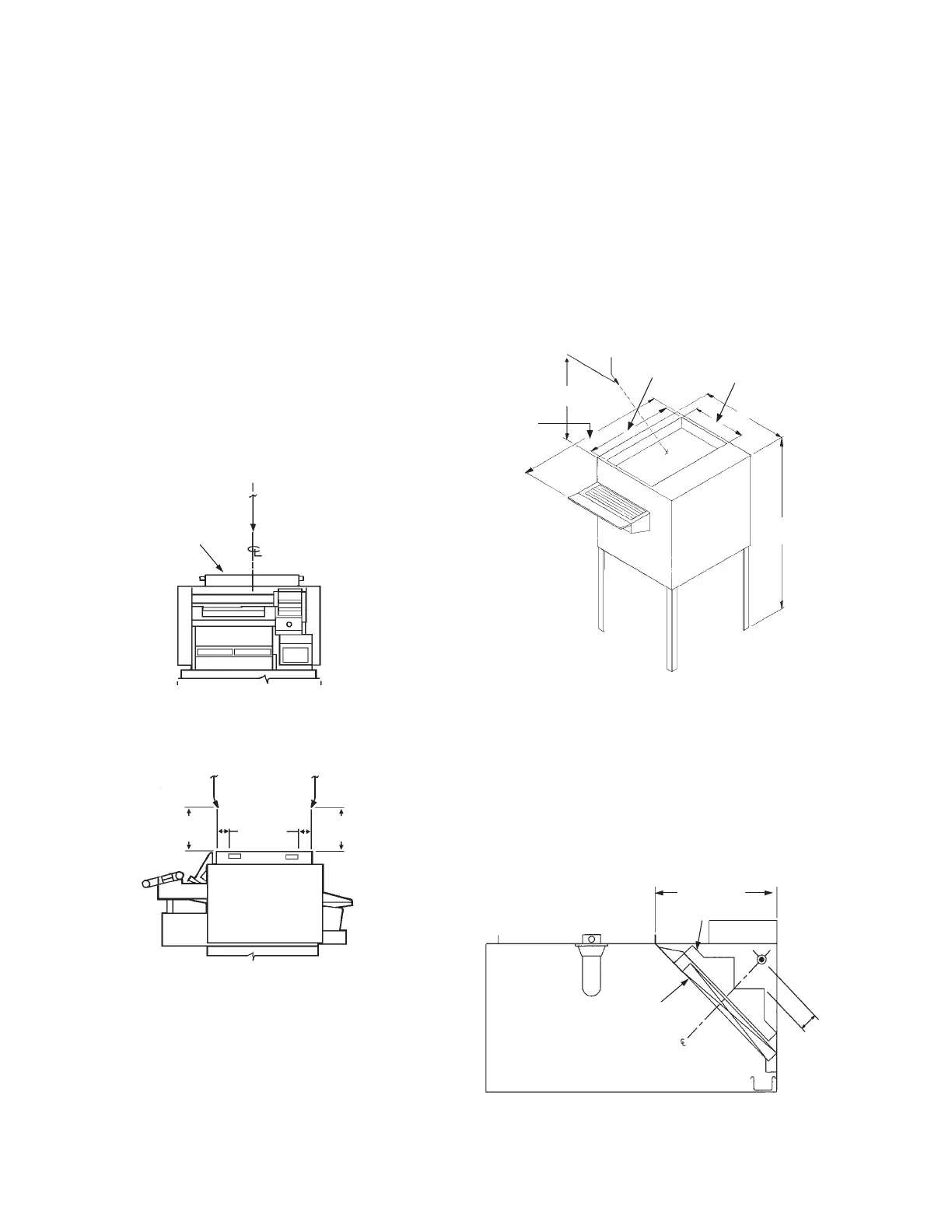

Marshall Air Electric Broiler – Model FR14B AutoBroil

Nozzle Quantity/Type: One 260 Nozzle

Nozzle Height:

15 – 20 in. (381 – 508 mm) above the

top of the broiler

Nozzle Location:

The nozzle must be centered above the

front edge of the broiler

Nozzle Aiming Point:

Aimed at the center of the exhaust

opening of the broiler. See Figure

4-103.

FIGURE 4-103

006737

Grease Grabber-80™ Two Stage Filtration System

The Grease Grabber-80 Two Stage Filtration System consists of

two components: The primary lter (The Grease-X Tractor) and

the secondary lter (The Grease Grabber-80).

The protection required for this application is the same as the

standard plenum/lter protection: One 1N nozzle protecting 10

(3.0 m) linear feet of plenum length by 4 ft (1.2 m) of plenum

chamber depth (width), positioned 2 in. to 4 in. (51 mm to 102 mm)

from peak of secondary lter. See Figure 4-104.

FIGURE 4-104

006526

15 – 20 IN.

(381 – 508 mm)

24.25 IN.

(615 mm)

24 IN.

(609 mm)

48 IN.

(1219 mm)

34.69 IN.

(881 mm)

14.50 IN.

(368 mm)

SECONDARY

FILTER

NOTE: TWO NOZZLES MUST BE UTILIZED FOR V-BANK FILTER

ARRANGEMENT.

PRIMARY

FILTER

1N

NOZZLE

2-4 IN.

(51-102 mm)

4 FT. (1.2 m)

MAXIMUM

Loading...

Loading...