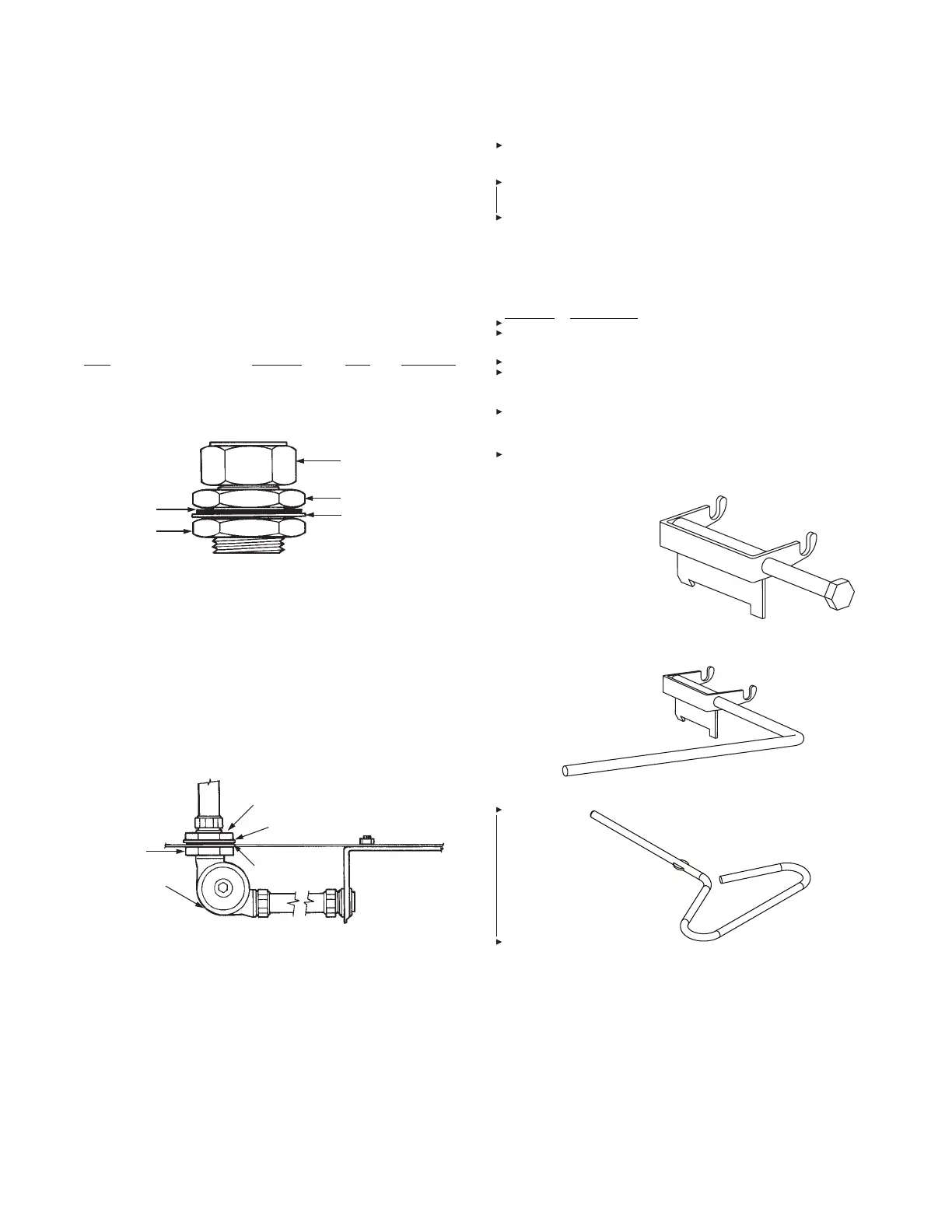

“COMPRESSION-SEAL” ADAPTOR

This adaptor is a mechanical bulkhead fitting that produces a

liquid-tight seal around pipe and conduit when installing distribu-

tion piping and detection conduit through restaurant hoods and

ducts. The “Compression-Seal” adaptor is a straight-through

design requiring no cutting or threading of conduit or pipe. The

adaptor is available for pipe sizes of 1/4 in. (Part No. 79149),

3/8 in. (Part No. 79151), 1/2 in. (Part No. 79147), and EMT con-

duit size of 1/2 in. (Part No. 79153). Each “Compression-Seal”

Adaptor Shipping Assembly must be ordered as stated below:

Shipping

Assembly Hole Size

Size Part No. Qty. Required

1/4 in. Pipe / 1/2 in. tube 79149 24 3/4 in.

3/8 in. Pipe / 5/8 in. tube 79151 24 1 1/8 in.

1/2 in. Pipe 79147 24 1 1/8 in.

1/2 in. EMT Conduit 79153 24 1 1/8 in.

FIGURE 3-20

000155

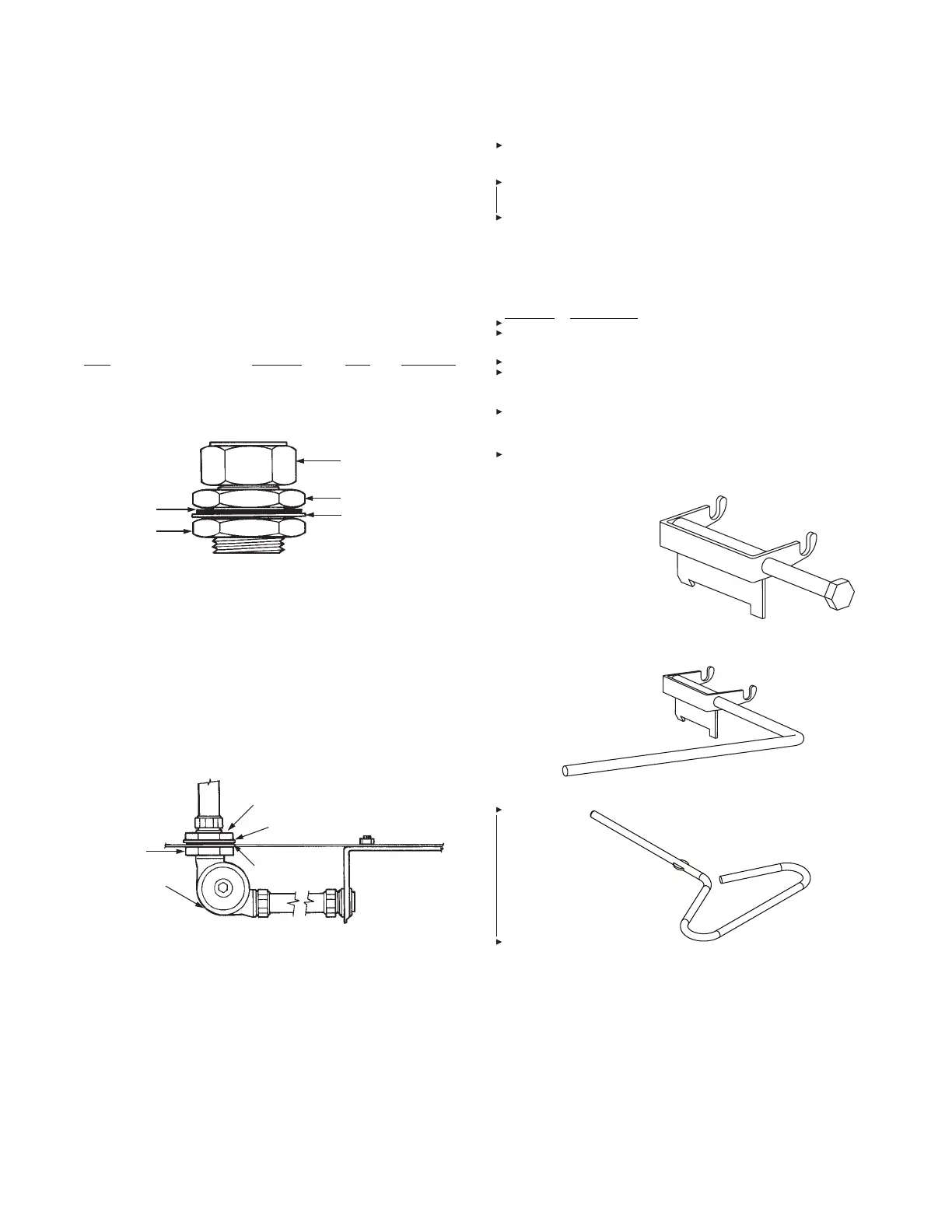

“HOOD SEAL” ADAPTOR ASSEMBLY

This adaptor is a mechanical bulkhead fitting that produces a

liquid-tight seal around 1/2 in. EMT conduit when installing the

detection line through restaurant hoods and duct. The adap-

tor accepts a high temperature pulley elbow and, when used,

correctly positions the elbow or conduit in line with the conduit

adaptor hole in the detector bracket. The “Hood Seal” elimi-

nates the need for multiple elbows when penetrating the top of

a hood when installing the detection line. “Hood Seal” Adaptors

are available in quantities of six as Shipping Assembly Part No.

423253.

FIGURE 3-21

000156

COCKING LEVER/LOCK PIN

The cocking lever is a component required to cock (arm) both

the mechanical/electrical AUTOMAN release and the mech-

anical gas valve. After the AUTOMAN is cocked (armed), the

lock pin must be inserted to eliminate the accidental firing of

the release mechanism. These components are available as

either an individual shipping assembly or a shipping assembly

containing both. Listed below are the various shipping assem-

bly part numbers.

Part No. Description

441042 Short Handle Cocking Lever with Lock Pin

(Mechanical/Electrical AUTOMAN)

441041 Long Handle Cocking Lever with Lock Pin

(Mechanical/Electrical AUTOMAN)

26310 Cocking Lever only (AUTOMAN II-C)

416018 Cocking Lever only (Mechanical Gas Valve)

438031 Lock Pin

Short Handle Cocking Lever

*Requires a crescent wrench or

open end/box wrench

*

Long Handle Cocking Lever

Lock Pin

FIGURE 3-22

008325

SECTION 3 – SYSTEM COMPONENTS

UL EX3470 ULC EX3470

2014-SEP-01 REV. 11 PAGE 3-7

R-102 Restaurant Fire Suppression Manual

SEAL

ADAPTOR

BODY

SEAL NUT

WASHER

PULLEY

ELBOW

(NOT PART

OF ASSEMBLY)

USE ONLY PULLEY ELBOW, PART NO. 423250

GASKET

COMPRESSION NUT

ADAPTOR BODY

LOCKWASHER

GASKET

NUT

Loading...

Loading...