SECTION 5 – INSTALLATION INSTRUCTIONS

UL EX3470 ULC EX3470

PAGE 5-24 REV. 11 2014-SEP-01

R-102 Restaurant Fire Suppression Manual

INSTALLATION OF REMOTE MANUAL PULL STATION OR

MECHANICAL GAS VALVE UTILIZING FLEXIBLE CONDUIT

(Continued)

Connecting the Flexible Conduit to the AUTOMAN

Release, Electrical Junction Box, or Mechanical Gas Valve

(Continued)

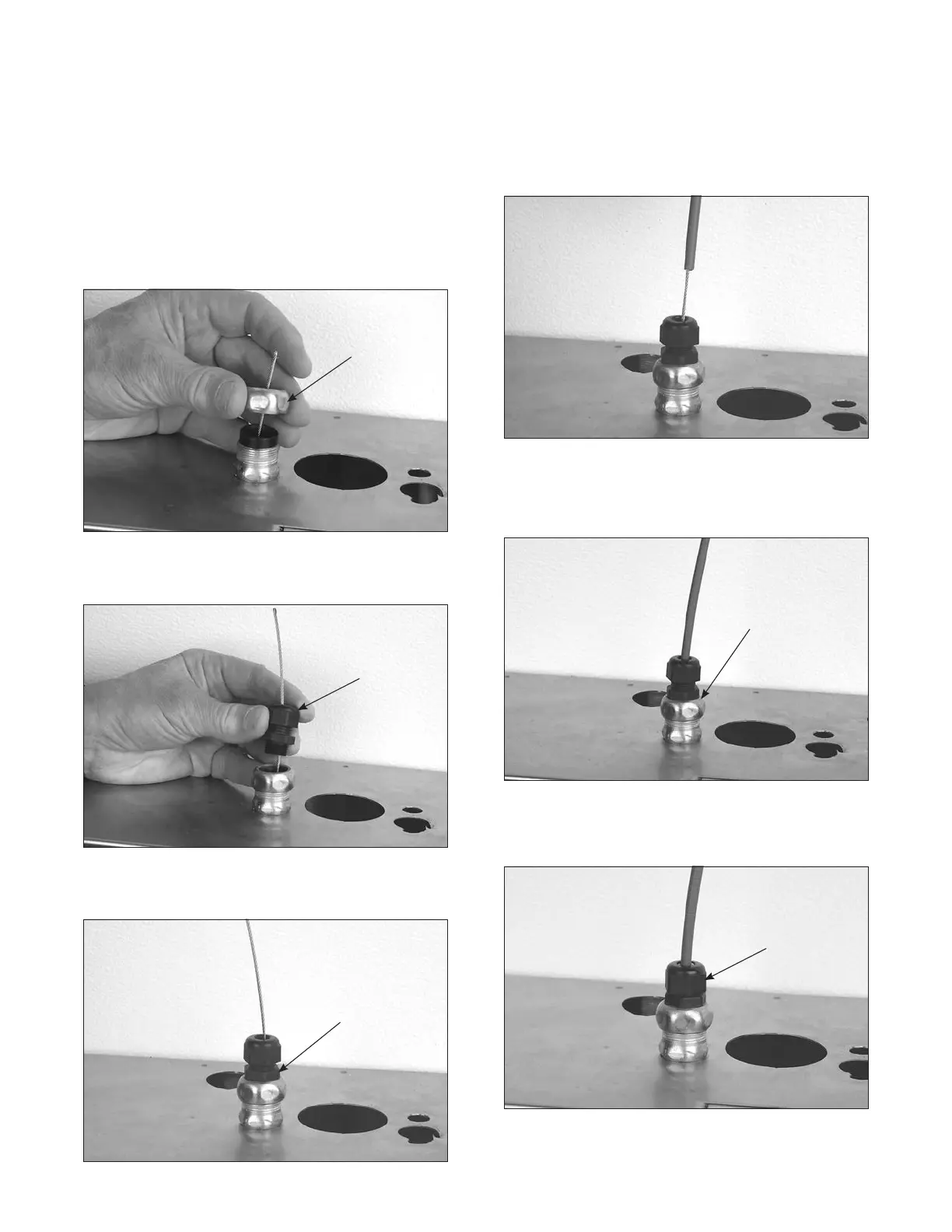

5. Tighten the nut to the connector body, locking the flexible

conduit insert in place. See Figure 5-56.

TIGHTEN

CONNECTOR

NUT TO LOCK

IN FLEXIBLE

CONDUIT

INSERT

FIGURE 5-56

007989

6. Loosen the nut on the strain relief and thread the wire rope

through a strain relief. See Figure 5-57.

LOOSEN

NUT

FIGURE 5-57

007990

7. Tighten the body of the strain relief to the conduit connector.

See Figure 5-58.

TIGHTEN

STRAIN RELIEF

INTO CONDUIT

CONNECTOR

FIGURE 5-58

007991

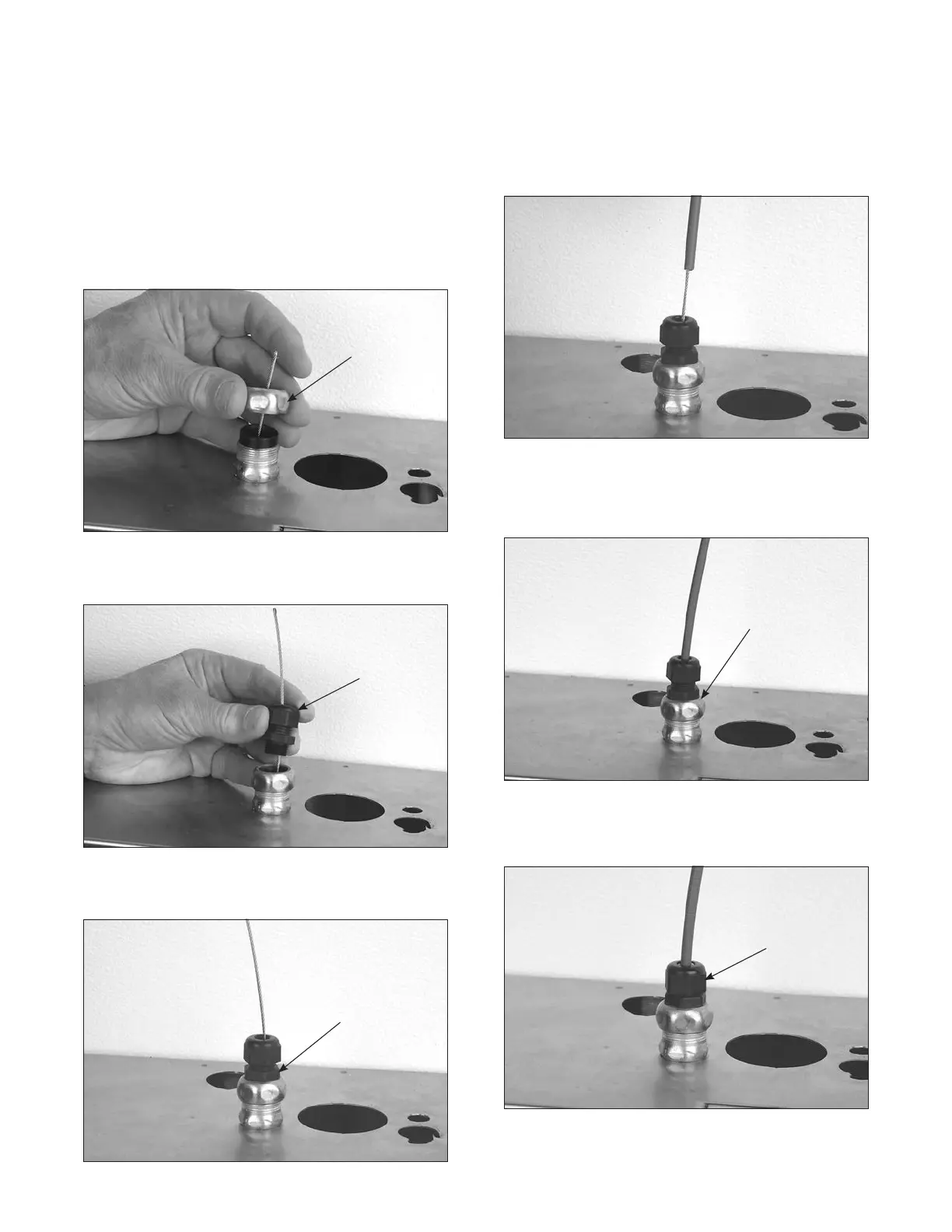

8. Thread the wire rope through the flexible conduit. See

Figure 5-59. (If a splice is required in the flexible conduit,

proceed to “Splicing Installation Instructions.”

FIGURE 5-59

007992

9. Slide the flexible conduit into the strain relief until it is

approximately 1/16 in. (1.6 mm) from the bottom of the flex-

ible conduit insert. See Figure 5-60.

STOP FLEXIBLE

CONDUIT

APPROXIMATELY

1/16 IN. (1.6 mm)

FROM THE BOTTOM

OF INTERNAL

FLEXIBLE CONDUIT

INSERT

FIGURE 5-60

007993

10. Tighten the strain relief nut onto the strain relief. See Figure

5-61.

TIGHTEN NUT

ON STRAIN

RELIEF

FIGURE 5-61

007994

Loading...

Loading...