SECTION 4 – SYSTEM DESIGN

UL EX3470 ULC EX3470

PAGE 4-66 REV. 11 2014-SEP-01

R-102 Restaurant Fire Suppression Manual

DISTRIBUTION PIPING REQUIREMENTS (Continued)

Distribution Piping Requirements – 1.5 Gallon System

DUCT, PLENUM, AND APPLIANCE PROTECTION

1. This option allows for duct protection, plenum protection,

appliance protection, or any combination. However, only one

duct nozzle may be used, either a 1W or a 2W, nozzle.

2. All distribution piping, supply and branch, must be 3/8 in.

Schedule 40 black iron, chrome-plated, or stainless steel.

3. Each 1.5 gallon tank allows a maximum of ve ow

numbers.*

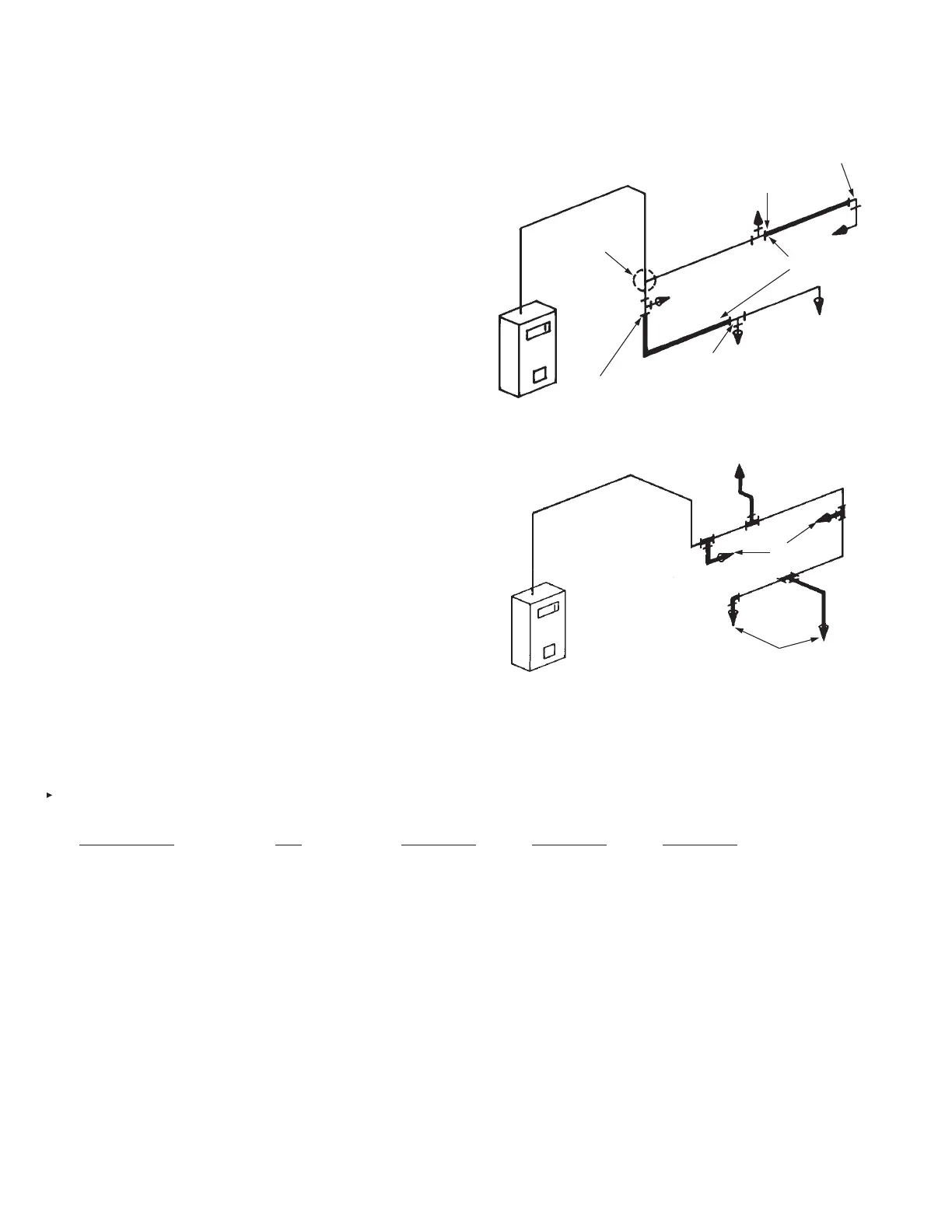

4. The pipe length between the start of the rst branch line and

the start of the last branch line must not exceed 8 ft (2.4 m).

When the supply line is split, the combined length of both

legs of the supply line (start of rst branch line to start of last

branch line) must not exceed 8 ft (2.4 m). See Figure 4-132.

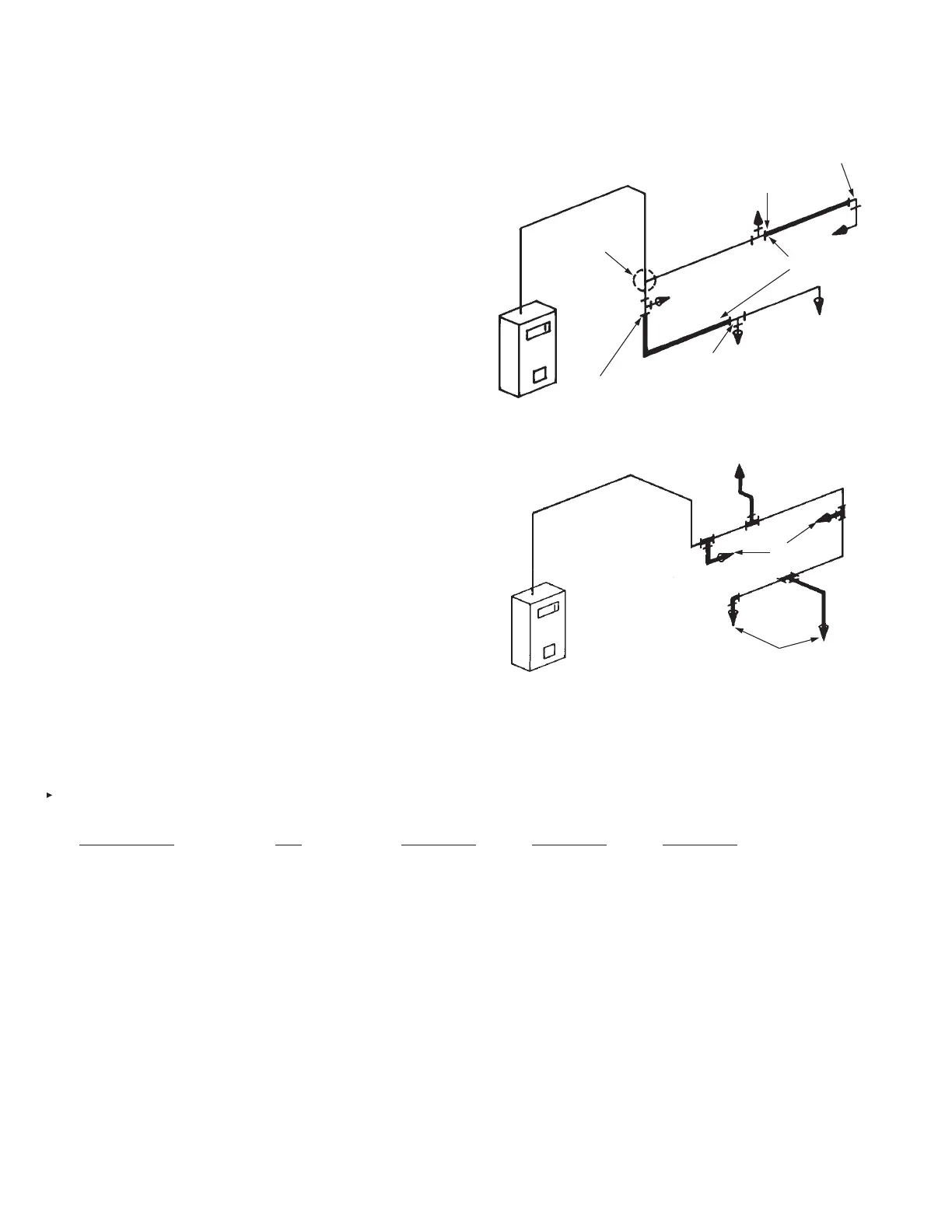

5. The combined length of all branch lines must not exceed 22

ft (6.7 m). See Figure 4-133.

6. The requirements of the following table must not be

ex ceeded:

1.5 GALLON SYSTEM

Supply Duct Plenum Appliance

Requirements Line Branch Line Branch Line Branch Line

Pipe Size 3/8 in. 3/8 in. 3/8 in. 3/8 in.

Maximum Length 40 ft 6 ft 4 ft 10 ft

(12.1 m) (1.8 m) (1.2 m) (3.0 m)

Maximum Tees 1 1 2 3

Maximum Flow Numbers 5* 2 2 3

* Exceptions:

1. Six flow numbers are allowed when a duct branch line is the last branch line on the piping network and no 1N nozzles are used to protect woks or griddles.

2. Six flow numbers are allowed when six 1N nozzles are used and none of the nozzles are used to protect woks, griddles, ranges, and salamanders.

Note:

Only five flow numbers are allowed if a 1N nozzle is used for wok, griddle, range, or salamander protection.

3. Six flow numbers are allowed when only two 3N nozzles are used.

FIGURE 4-132

000784

SUPPLY

LINE TEE

START OF FIRST

BRANCH LINE

START OF LAST

BRANCH LINE

TOTAL LENGTH

MUST NOT

EXCEED 8 FT

(2.4 m)

START OF LAST

BRANCH LINE

START OF FIRST

BRANCH LINE

FIGURE 4-133

000785

1W NOZZLE

1N NOZZLE

COMBINED LENGTH MUST

NOT EXCEED 22 FT (6.7 m)

1N NOZZLE

(BRANCH LINES IN BOLD)

Loading...

Loading...