SECTION 6 – TESTING AND PLACING IN SERVICE

UL EX3470 ULC EX3470

PAGE 6-2 REV. 11 2014-SEP-01

R-102 Restaurant Fire Suppression Manual

TESTING MECHANICAL GAS VALVES (Continued)

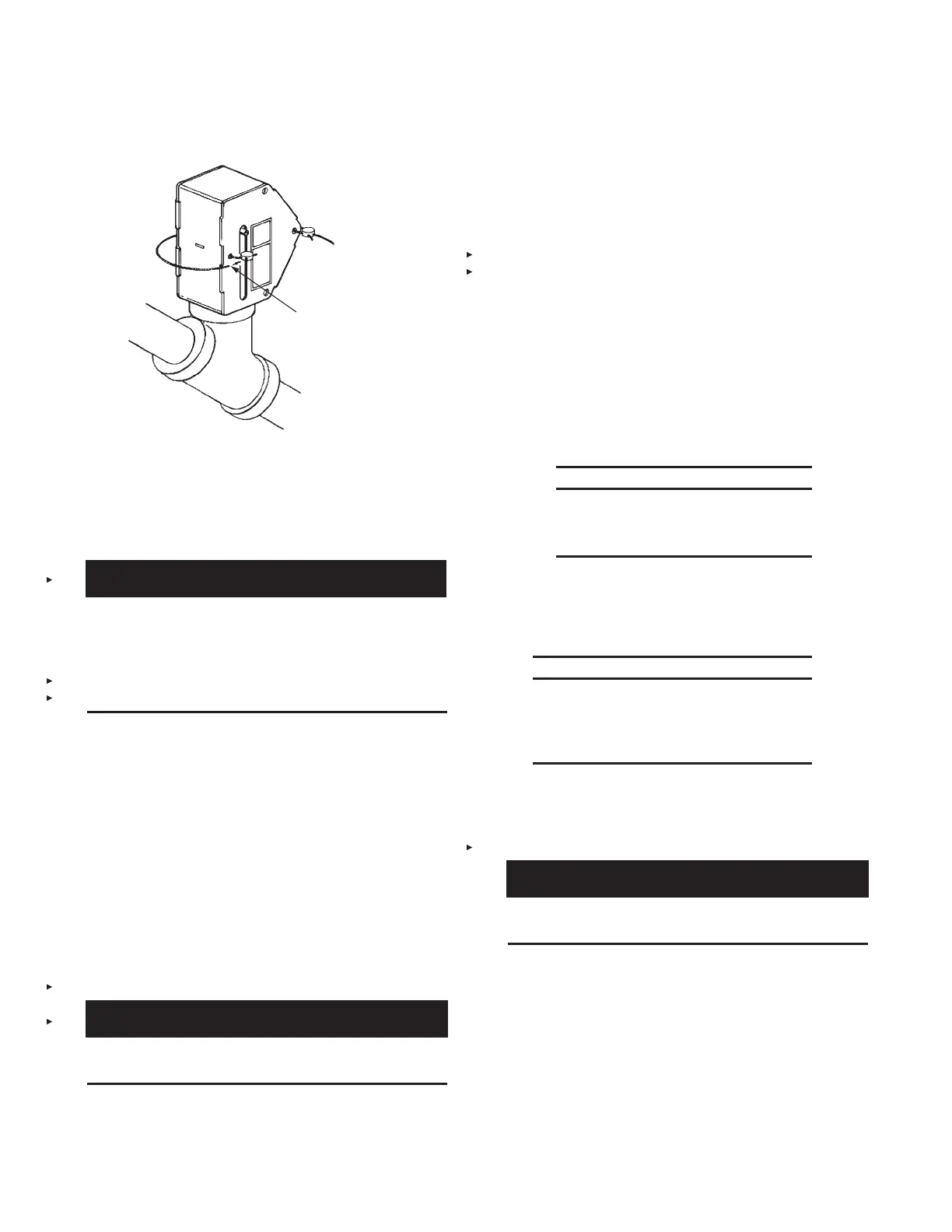

VISUAL INSPECTION

SEAL (PART NO. 197)

FIGURE 6-1

000359

TESTING ELECTRICAL GAS VALVES

To test each Electric Gas Shut-off Valve complete the following

steps:

1.

!

WARNING

To reduce the risk of explosion due to leaking gas, before

the gas line is turned on, make certain to extinguish any

open flames and turn off all burners and any electrical

or mechanical devices that are capable of igniting gas.

Failure to comply may result in serious personal injury or

death.

Turn gas line on.

2. Make certain electric (snap-action) switch is properly wired.

3. Make certain all other devices connected to the manual

reset relay are properly wired. Refer to typical wiring

diagrams in Figures 5-122, 5-123, 5-124, and 5-125 in

“Installation Instructions” section.

4. Test for gas leaks by painting connections with a soap

solution. Bubbles indicate a gas leak. Tighten connections

where leaks appear. Repeat test again to make certain no

other gas leaks exist.

5. If no gas leaks are found, turn power source on and depress

theresetbuttononthemanualresetrelay(REDLIGHTON)

to energize (OPEN) electric gas valve.

6. Remove lock pin from regulated release mechanism.

CAUTION

Do not install cartridge at this time or system may be

actuated.

7. Manually actuate the system by operating the remote pull

station. (It may be necessary to remove the glass break

rodpriortooperatingpullstation.)Manualresetrelay(RED

LIGHT OUT) will de-energize (CLOSE) the electric gas

valve, thus shutting off the gas line. If this does not happen,

turn power source off. Then re-examine all wiring connec-

tions for proper hookup. Refer to Figures 5-122, 5-123,

5-124, and 5-125 in ‘‘Installation Instructions’’ section for

typical wiring diagrams.

8. If test is successful, recock regulated release mechanism

using cocking lever (Part No. 441042 or 441041) and rein-

stall lock pin (Part No. 438301). Depress reset button on

manualresetrelay(REDLIGHTON).

9. Check burners for gaseous odor. IF GASEOUS ODOR

EXISTS, TURN OFF POWER SOURCE IMMEDIATELY.

This will cause the electric gas valve to shut the gas line off.

Open any doors and/or windows to clear the area of

gaseous fumes, then correct the gas leak before proceeding

any further.

10. If no gaseous odor exists, pilot light may be ignited at this

time.

NOTICE

If no other devices are being attached,

proceed to Page 6-3, Step No. 1, and test

the detection system.

TESTING ELECTRIC SWITCH

The procedure for testing a field installed electric (snap-action)

switch is as follows:

NOTICE

If an electrical gas shut-off valve is attached

to system, perform proper test procedure

for the gas valve first, before completing the

following steps.

1. Turn power source on and if installed, depress reset button

on manual reset relay (RED LIGHT ON). All electrical

devices should be operating at this time.

2. Remove lock pin.

CAUTION

Do not install cartridge at this time or system may be

actuated.

3. Manually actuate the system by operating the remote pull

station. It may be necessary to remove the glass break rod

prior to operating pull station. (If installed, the manual reset

relay will de-energize the electric gas valve, thus shutting

off the gas line.) All electrically-operated devices prede-

termined to shut off or turn on should do so. If this does

not occur, turn power source off and make sure all wiring

is properly connected and retest. Refer to Figures 5-122,

5-123, 5-124, and 5-125 in “Installation Instructions” section

for typical wiring diagrams.

Loading...

Loading...