SECTION 4 – SYSTEM DESIGN

UL EX3470 ULC EX3470

2014-SEP-01 REV. 11 PAGE 4-71

R-102 Restaurant Fire Suppression Manual

DETECTION SYSTEM REQUIREMENTS

Once the re suppression system design has been determined,

a detection system design must be completed. This section

contains guidelines and limitations for detection system instal-

lation.

Detector Identification

The two types of detectors are distinguished from each other by

their location in the detection system.

1. The Terminal Detector is the last in a series of detectors,

or the only detector used in a single-detector system. This

detector is thus named because it is at the point at which the

wire rope ends, or “terminates.”

2. A Series Detector is any detector located in-line between the

regulated release mechanism and the terminal detector.

Detector/Pulley Elbow/Conduit Offset Design Limitations

1. Conduit runs, pulley elbows, and number of detectors per

system must be within the approved system guidelines. The

following requirements must not be exceeded:

Maximum Maximum Maximum

Number of Number of Length of

Detectors Elbows 1/2 in. Conduit

per System per System per System

Scissors Style 15 20 150 ft (45.7 m)

Detector

(Without

Offset Conduit

Scissors Style 15 16 150 ft (45.7 m)

Detector (With

Offset Conduit

2. If the hazard requires more than 15 detectors, up to ve

101 Remote Releases (Part No. 433485) can be used for

system actuation. Each 101 remote release allows the use

of a maximum of 15 “scissor” style detectors (14 series and

1 terminal) for a total of 75 detectors if needed.

Detector Placement Requirements

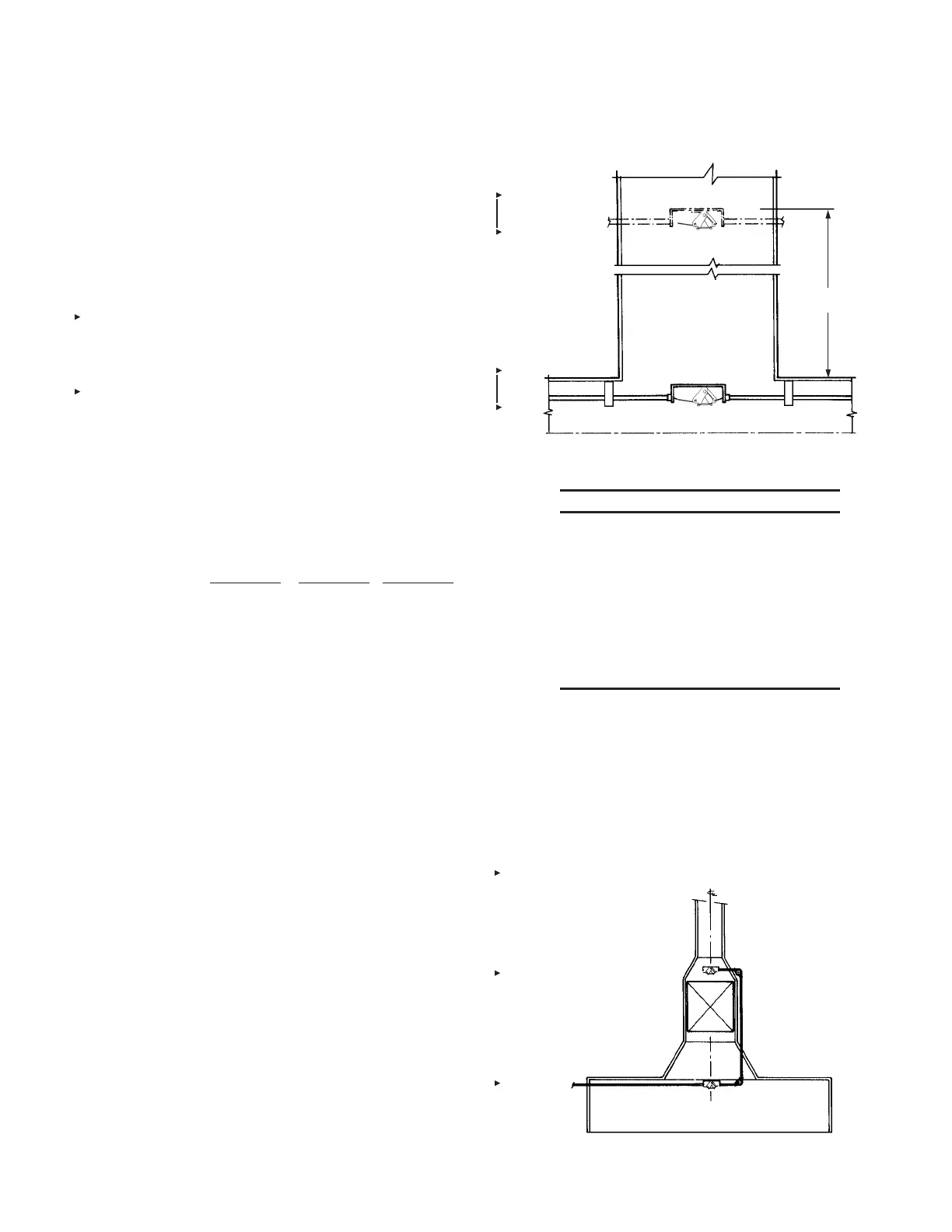

EXHAUST DUCTS

Each exhaust duct must have at least one detector installed

in the duct entrance, located in the airstream of the cooking

vapors, or at a maximum of 20 ft (6.0 m) into the duct opening.

See Figure 4-139

FIGURE 4-139

000271

NOTICE

When gas appliances are used and the flue

gases from the burner are exhausted into the

duct, the detector must be kept out of the air

stream of these exhaust gases. These gases

can be very hot and could actuate the system

unnecessarily.

Duct openings that are long and narrow or

large enough to require multiple duct nozzles

may require additional detectors.

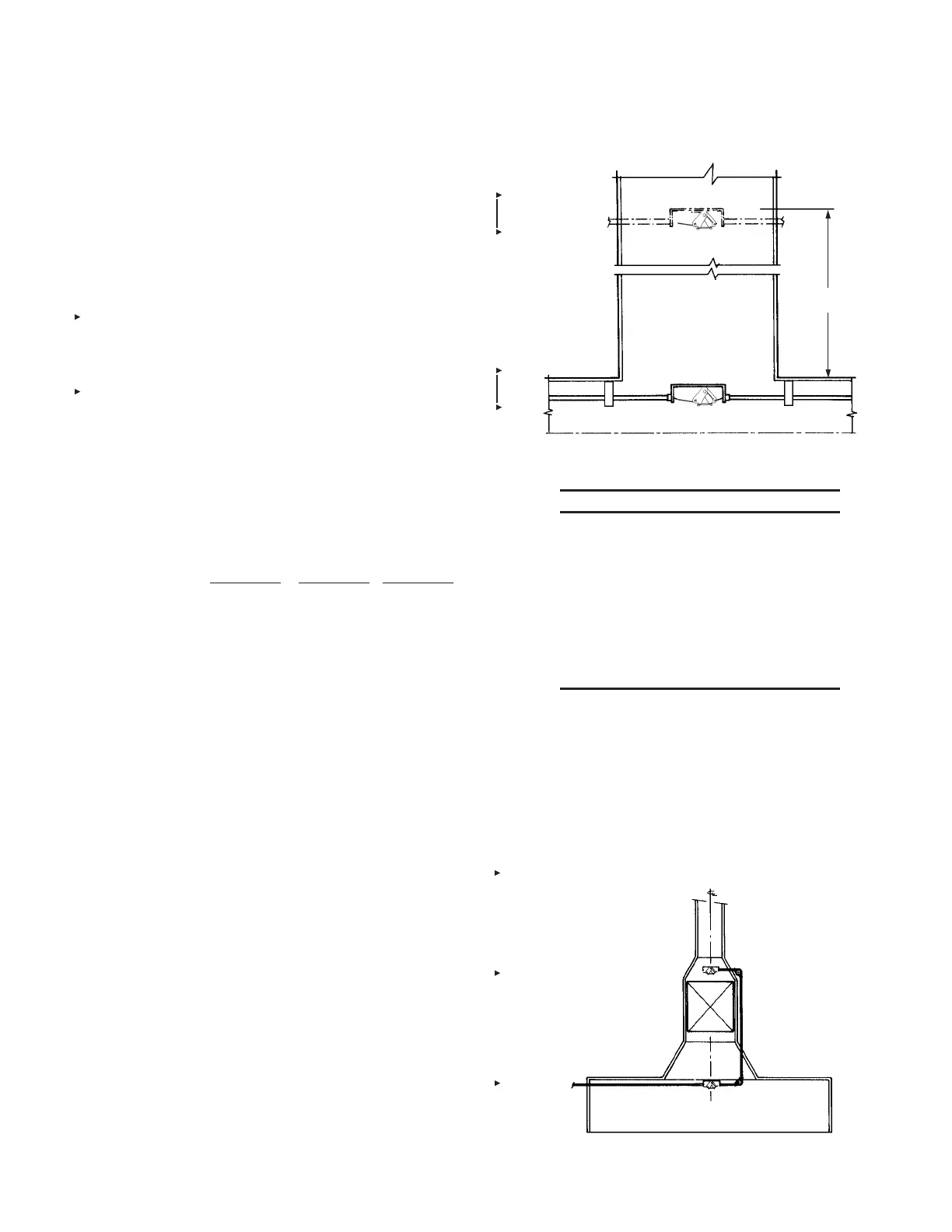

ELECTROSTATIC PRECIPITATOR

If an electrostatic precipitator is located at or near the base of

the exhaust duct, it is necessary to locate a detector below the

precipitator, at the base of the duct, and also locate one in the

duct, just above the precipitator. See Figure 4-140.

When installing the detector bracket and system conduit, make

certain they do not interfere with the operation of the precipitator.

Note:

On secondary ltration units utilizing multiple lter stages/

media, contact Technical Services for instructions.

FIGURE 4-140

000268

20 FT (6.0 m)

MAXIMUM

Loading...

Loading...