SECTION 4 – SYSTEM DESIGN

UL EX3470 ULC EX3470

PAGE 4-70 REV. 11 2014-SEP-01

R-102 Restaurant Fire Suppression Manual

DISTRIBUTION PIPING REQUIREMENTS (Continued)

Distribution Piping Requirements – 9.0 Gallon System

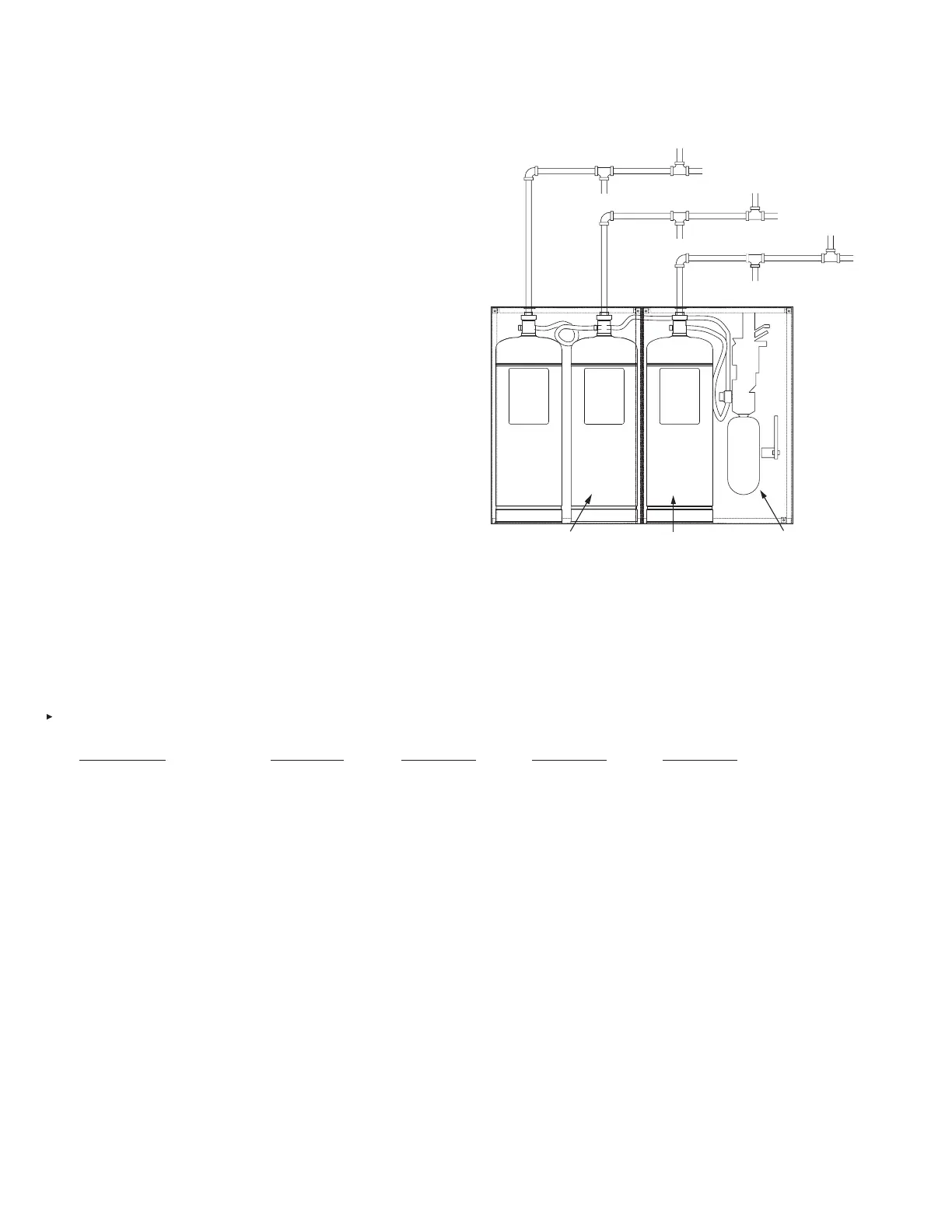

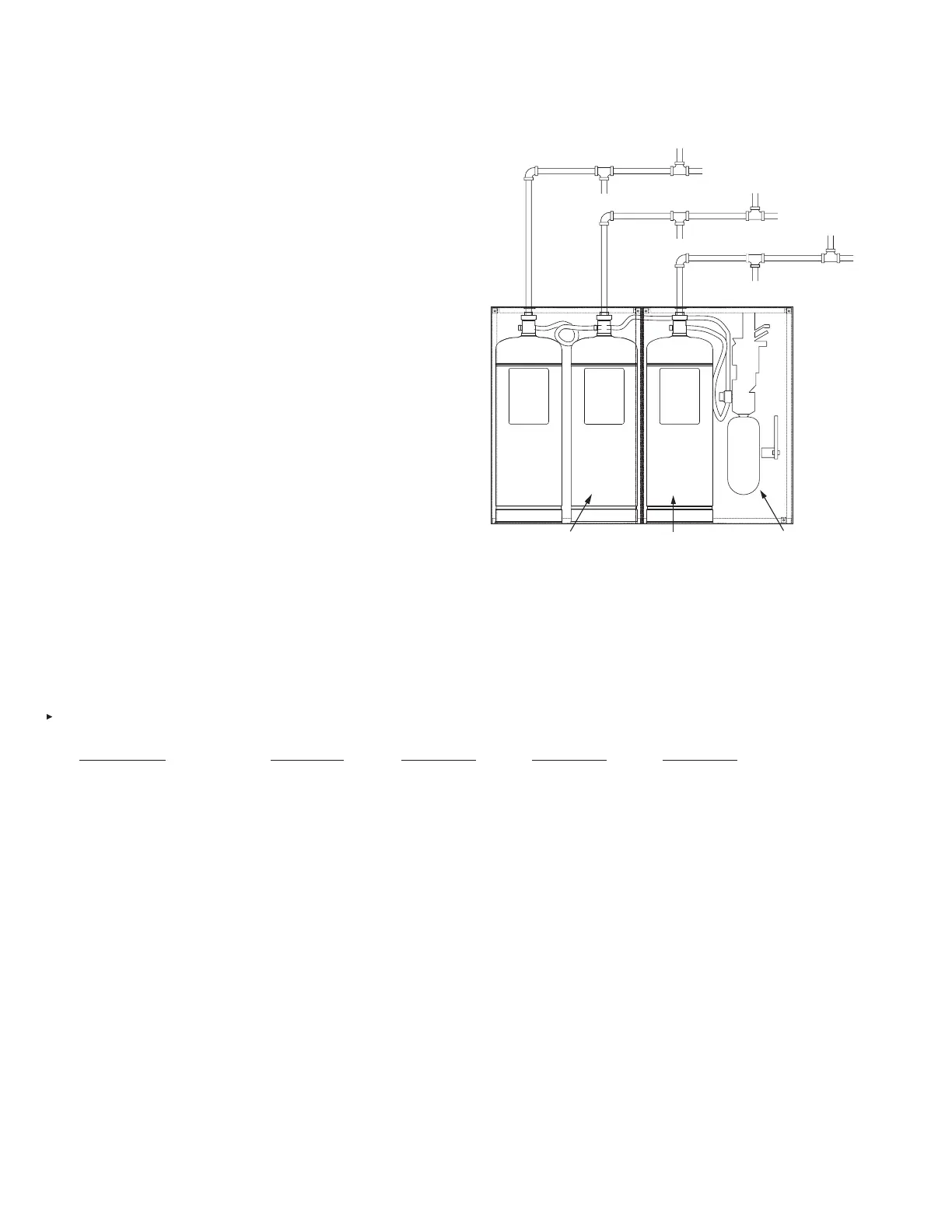

This optional conguration consists only of three 3-gallon tanks,

all pressurized from a single double-tank nitrogen cartridge with

expellant gas hoses connected as shown in Figure 4-138. Tanks

No. 1 and No. 2 must be connected directly to the regulator with

separate expellant gas hoses and Tank No. 3 must be connected

to Tank No. 2 with a third expellant gas hose as shown in Figure

4-136. Each tank must be connected to an independent distribu-

tion piping network as shown in Figure 4-138. Distribution piping

requirements for each network must be as follows:

1. The maximum length between the start of the rst branch

line and the start of the last branch line must not exceed

24 ft (7.3 m). When the supply line is split, the combined

total of both legs of the supply line (from the start of the

rst branch line to the start of the last branch line) must not

exceed 24 ft (7.3 m). See Figure 4-134.

2. The total length of all branch lines must not exceed 36 ft

(10.9 m). See Figure 4-138.

3. Use a 3/8 in. union to connect the tank adaptor to the 3/8 in.

supply line.

4. A maximum of two nozzles are allowed per duct branch line.

5. When using this 9.0 gallon system conguration, no mani-

folding of distribution piping is allowed.

6. When an AUTOMAN Regulated Release is utilized in this

conguration, additional regulator actuators cannot be used.

7. Only 3-gallon tanks can be utilized in this conguration.

8. The requirements of the following table must not be

exceeded for each 3-gallon tank:

9.0 GALLON SYSTEM

Duct Plenum Appliance

Requirements Supply Line Branch Line Branch Line Branch Line

Pipe Size 3/8 in. 3/8 in. 3/8 in. 3/8 in.

Maximum Length 40 ft 8 ft 4 ft 12 ft

(12.1 m) (2.4 m) (1.2 m) (3.6 m)

Maximum Rise 6 ft 4 ft 2 ft 2 ft

(1.8 m) (1.2 m) (0.6 m) (0.6 m)

Maximum 90° 9 4 4 6

Elbows

Maximum Tees 1 2 2 4

Maximum Flow 11* 4 2 4

Numbers

* Exceptions:

1. Twelve flow numbers are allowed in any one tank for duct and plenum protection ONLY.

2. Twelve flow numbers are allowed with any one tank using only two-flow appliance nozzles.

3. Twelve flow numbers are allowed with any one tank using only three-flow appliance nozzles.

Special Instructions:

1. When four Dean Industries GTI Gas Fryers are protected at low proximity as shown in Figure 4-66 on Page 4-32, the discharge piping must be as shown in Figure 4-67 on

Page 4-32.

2. For certain McDonald’s applications, 11.5 flow numbers are allowed when using a combination of one 2W duct nozzle, one 1/2N electrostatic precipitator nozzle,

one 1N plenum nozzle, and four two-flow appliance nozzles. Contact the Applications Engineering Department for additional information.

FIGURE 4-138

008126

3.0

GALLON

TANK

NO. 3

3.0

GALLON

TANK

NO. 2

3.0

GALLON

TANK

NO. 1

3 GALLON REGULATED

RELEASE ASSEMBLY,

OR 3 GALLON

REGULATED

ACTUATOR ASSEMBLY

TWO TANK ENCLOSURE

ASSEMBLY (PART NO.

430324) (INCLUDES

HOSES AND GROMMETS)

DOUBLE TANK NITROGEN

CARTRIDGE OR

LT-A-101-30 CARTRIDGE

(REGULATED ACTUATOR

ONLY)

NOTE: WHEN THREE 3.0 GALLON TANKS ARE CONNECTED TO ONE

AUTOMAN REGULATED RELEASE ASSEMBLY, NO ADDITIONAL

REGULATED ACTUATOR(S) ASSEMBLIES CAN BE USED.

Loading...

Loading...