SPECIFIC APPLICATION BY MODEL (Continued)

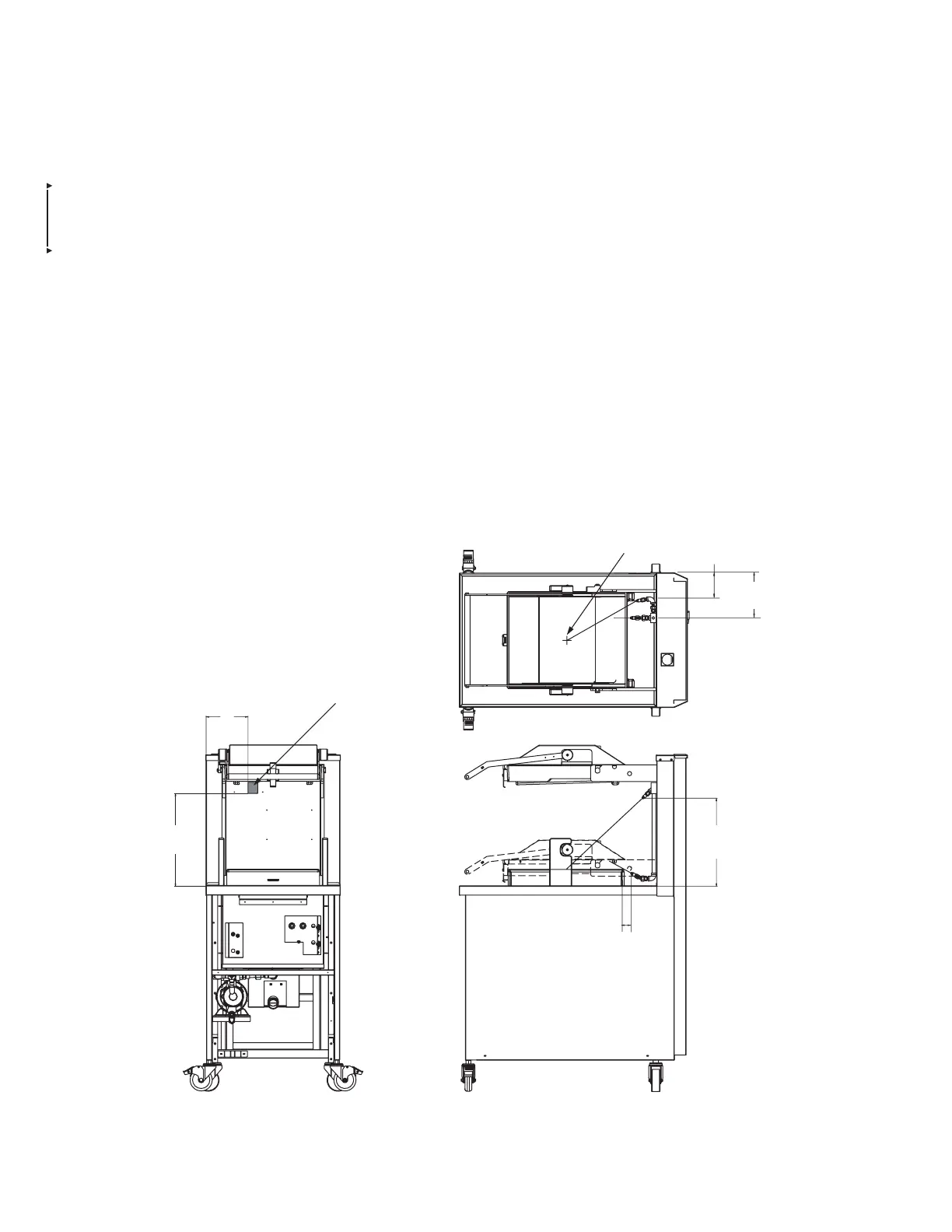

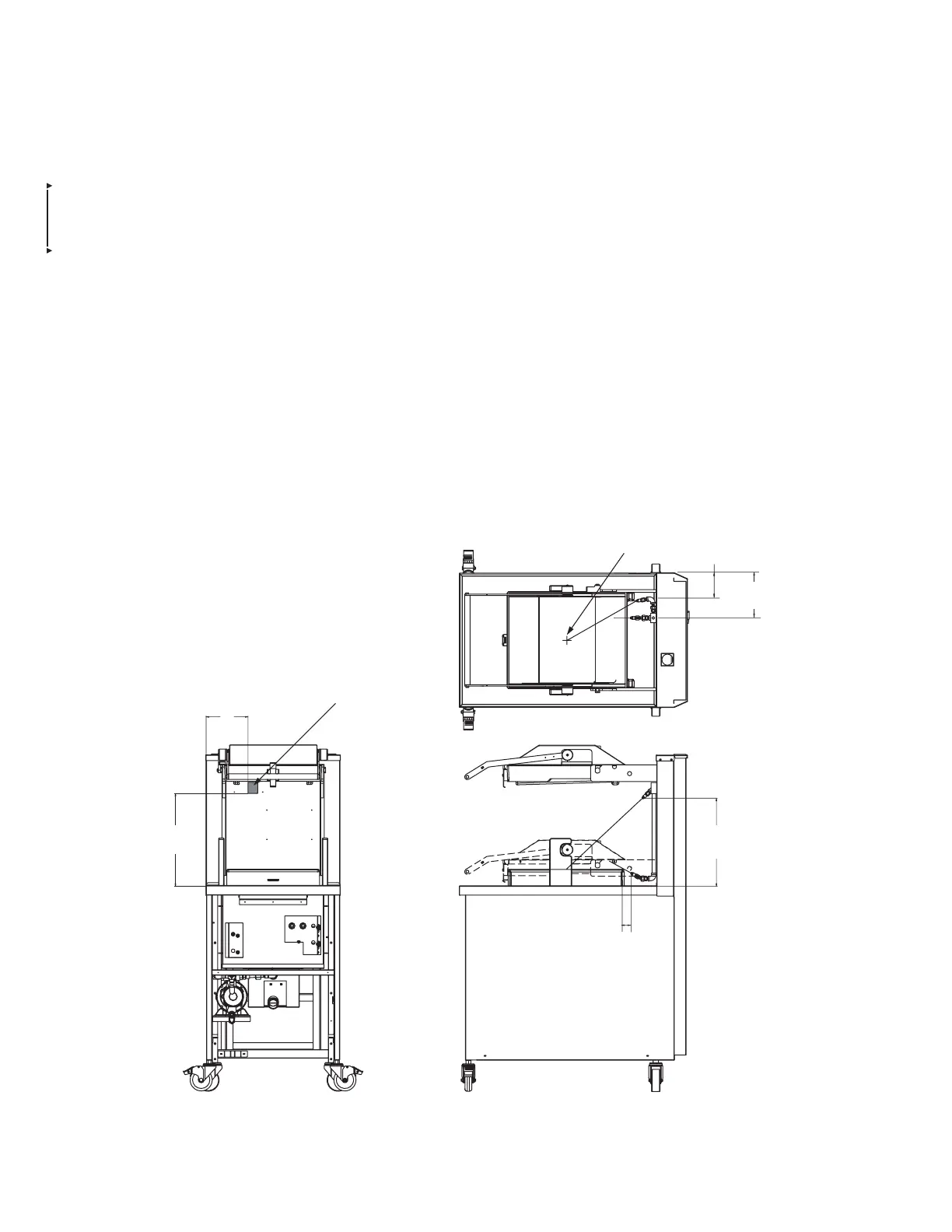

Henny Penny Dual Lift System – Models 580, 581, 582, 590,

591, 592, 680, 682, 691

Nozzle Type: One 1N nozzle (Upper position)

One 1F nozzle (Lower position)

Nozzle Location:

1N Nozzle (Upper position): From the Tee Block, position

nozzle tip 16 in. (406 mm) up from base of fryer surface and

5 in. (127 mm) in from left side of appliance back shroud

1F Nozzle (Lower position): Running down from the Tee Block

to the base of the fryer, position the nozzle tip 2 in. (51 mm) from

back side of fry vat, and 8 in. (203 mm) in from the left side of

appliance back shroud.

Nozzle Aiming Point:

1N Nozzle: At center point of fry vat

1F Nozzle: The 1F nozzle is a at spray nozzle and the spray

must be horizontal to that of the edge of the back lip of the fry vat

System Coverage: Each fryer requires a minimum of 3 gal

(11.4 L) of ANSULEX Low pH agent discharging through the two

one-ow nozzles (1N and 1F)

Note: In this application, R-102 agent storage tanks must

be pressurized from a dedicated R-102 double-tank nitrogen

cartridge. The cartridge utilized for this hazard-specic Henny

Penny fryer protection cannot be shared with tanks intended

for standard R-102 protection. Standard protection will require

an expellant gas cartridge installed in another actuation device

such as an AUTOMAN regulated release or regulated actuator

assembly.

FIGURE 4-73

007515

16 IN.

(406 mm)

16 13/16 IN.

(427 mm)

8 IN.

(203 mm)

2 IN.

(51 mm)

5 IN.

(127 mm)

7 9/16 IN.

(192 mm)

SIDE VIEW

TOP VIEW

FRONT VIEW

(TEE BLOCK LOCATION)

AIMING POINT

TEE

BLOCK

NOTE 1: IT IS RECOMMENDED THAT THE AGENT DISTRIBUTION

HOSE KIT (PART NO. 435982) BE UTILIZED DURING SYSTEM

INSTALLATION.

NOTE 2: VAT DIMENSIONS –

16 IN. (406 mm) WIDTH

20 1/4 IN. (514 mm) LENGTH

28 1/2 IN. (724 mm) DEPTH

MAXIMUM LID HEIGHT ABOVE VAT –

15 IN. (381 mm)

SECTION 4 – SYSTEM DESIGN

UL EX3470 ULC EX3470

PAGE 4-36 REV. 11 2014-SEP-01

R-102 Restaurant Fire Suppression Manual

Loading...

Loading...